A method and device for sealing electrodes in a hydrogenation furnace device for polysilicon production

A technology of hydrogenation furnace and polysilicon, which is applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of hydrogen easy to cause fire, short circuit of electrodes and chassis, insulation failure, etc., to improve conversion rate and production The effect of improving efficiency, increasing working pressure and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

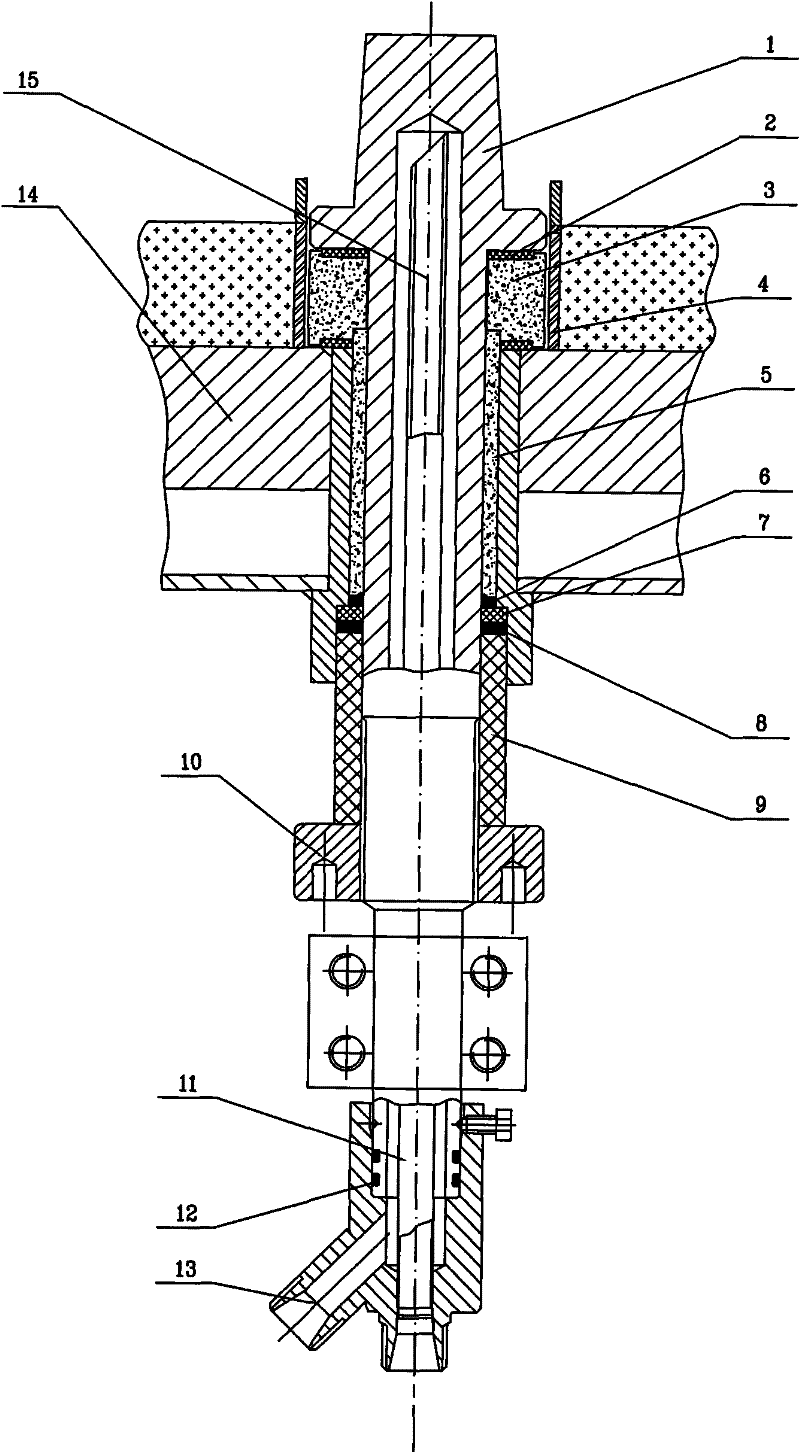

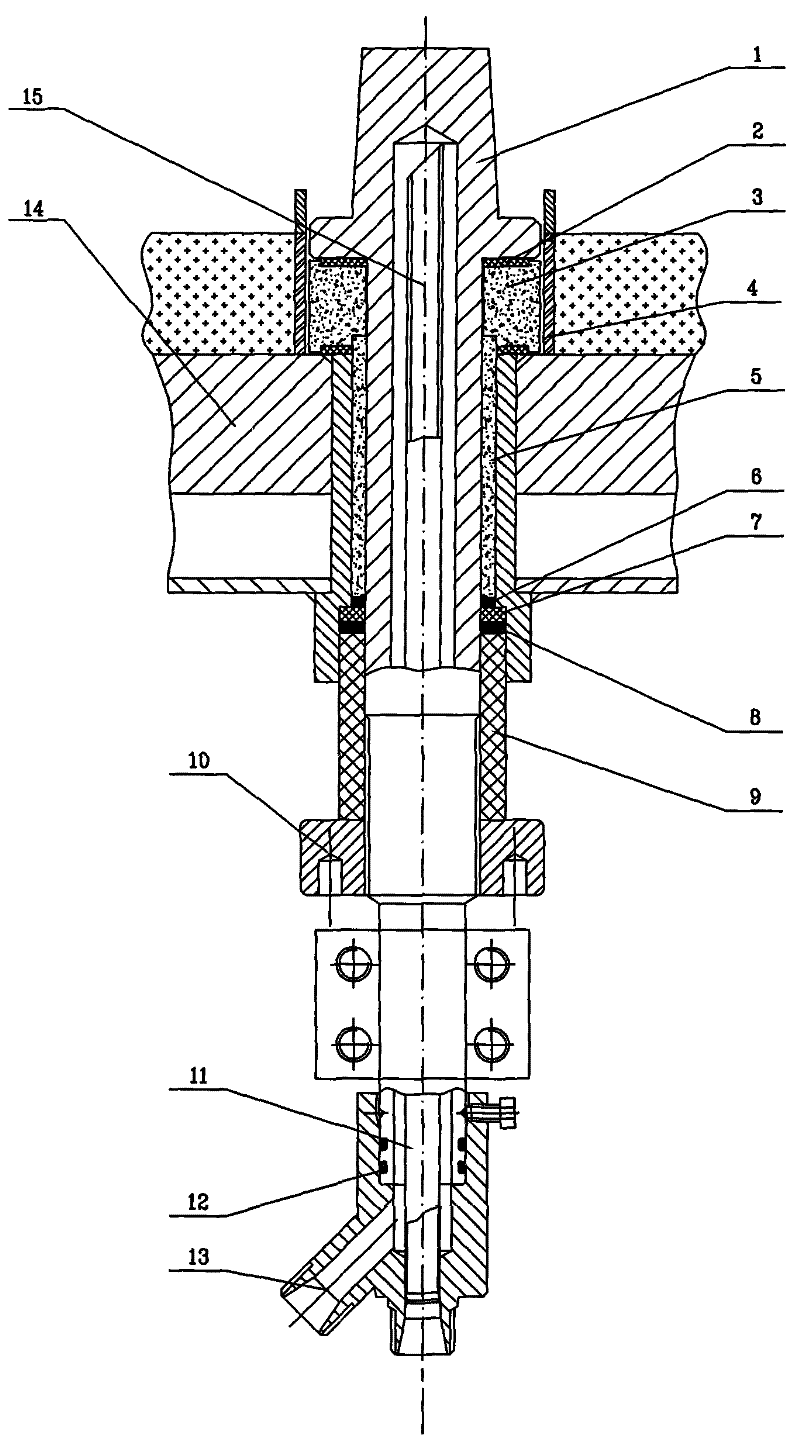

[0021] Such as figure 1 As shown, a method for sealing electrodes in a hydrogenation furnace device for polysilicon production, a zirconia ceramic sealing device, a flexible graphite sealing ring and an O-ring are set between the electrode 1 and the chassis 14 to jointly realize high temperature resistance, insulation and Sealing, tighten the stainless steel nut 10, the electrode 1 and the chassis 14 and the glass fiber bushing 9 are tensioned, so that the flexible graphite sealing ring, the O-ring and the polytetrafluoroethylene backing ring 7 are pressed and deformed to form a seal, and at the same time, the electrode 1 into the cooling water.

[0022] A device for sealing electrodes in a hydrogenation furnace device for polysilicon production, including a chassis 14, an electrode 1 is connected to the chassis 14 through a stainless steel nut 10, a boss is arranged under the top of the electrode 1, and a quartz tube 4, Flexible graphite sealing ring 2, zirconia ceramic insu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| electrical insulator | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com