Aluminum oxidation wastewater treatment and reclaimed water reuse technology

A technology for wastewater treatment and aluminum oxidation, which is applied in water/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc. The effect of small land area, high reclaimed water reuse rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

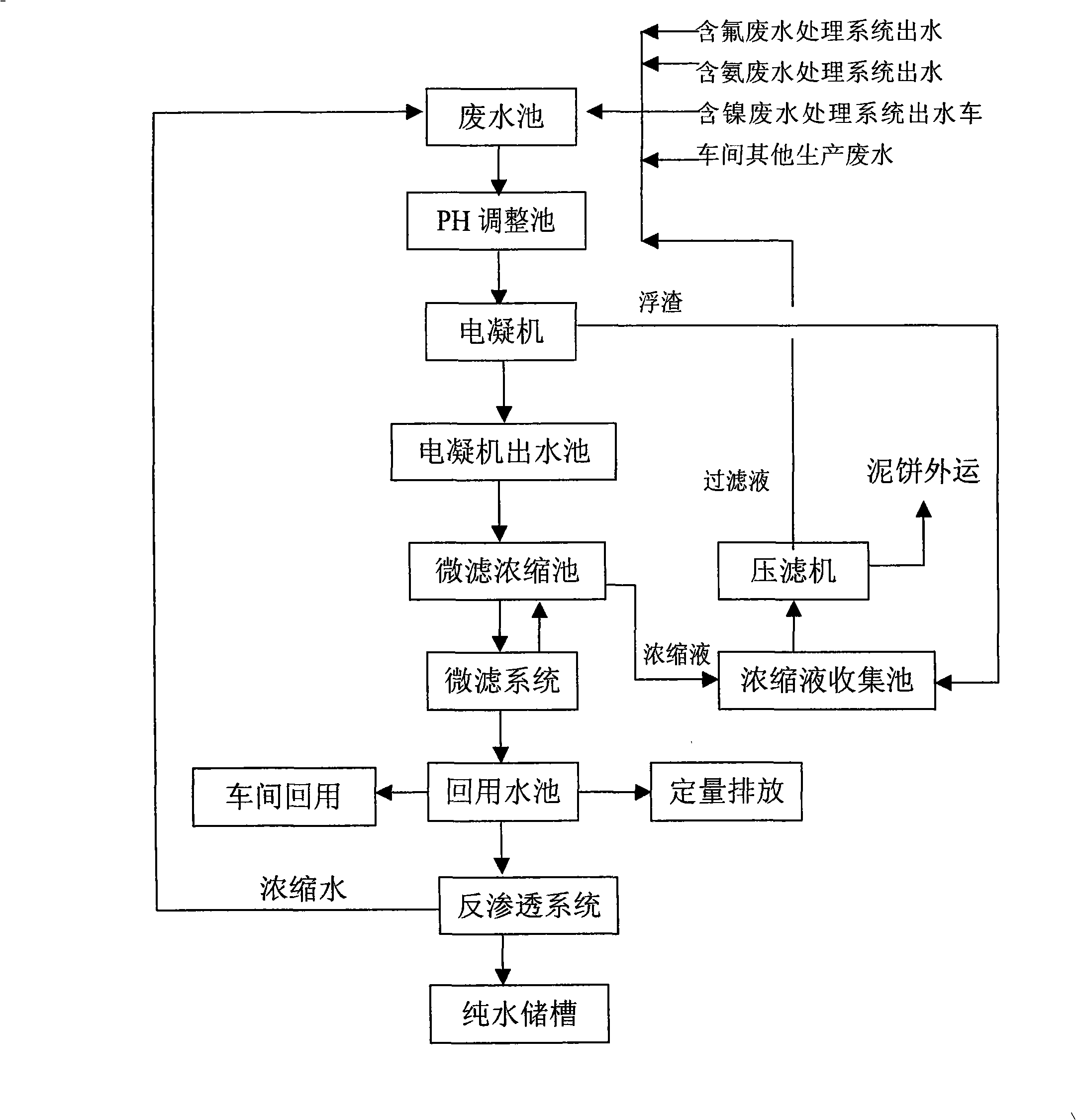

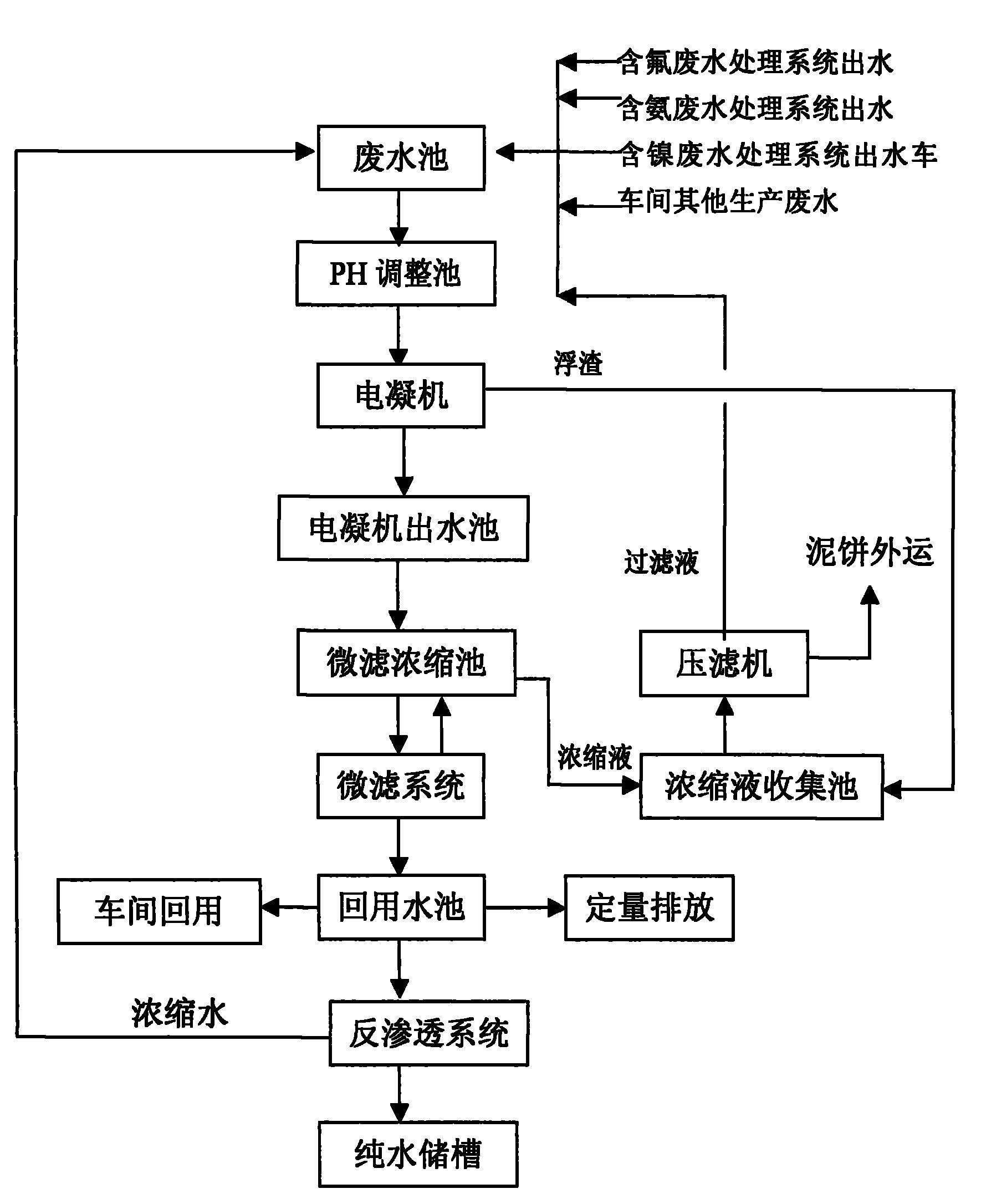

[0023] see figure 1 , the present invention relates to a method for treating aluminum oxidation wastewater and reclaimed water, in which high fluorine-containing wastewater, ammonia-containing wastewater and nickel-containing wastewater are pretreated respectively, and then discharged together with other production wastewater in the workshop to the wastewater pool;

[0024] Transport the water in the wastewater tank to the pH adjustment tank, adjust the pH to 4-6 in the pH adjustment tank, and then transport it to the electrocoagulation machine for electrocoagulation treatment. The wastewater after electrocoagulation treatment enters the electrocoagulation outlet pool, and Add alkali to the electrocoagulation outlet pool, adjust the pH value to 7-8, and then add activated carbon powder accounting for 2‰~5‰ of the water weight of the electrocoagulation outlet pool;

[0025] The wastewater from the electrocoagulation pool is transported to the microfiltration concentration pool,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com