Method for directly synthesizing dimethyl ether by CO2 of slurry reactor

A dimethyl ether and slurry bed technology, which is applied in the field of simultaneously producing clean fuel dimethyl ether and methanol, can solve the problem of low single-pass yield of methanol and DME, and achieve significant economic benefits, increase economic efficiency, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

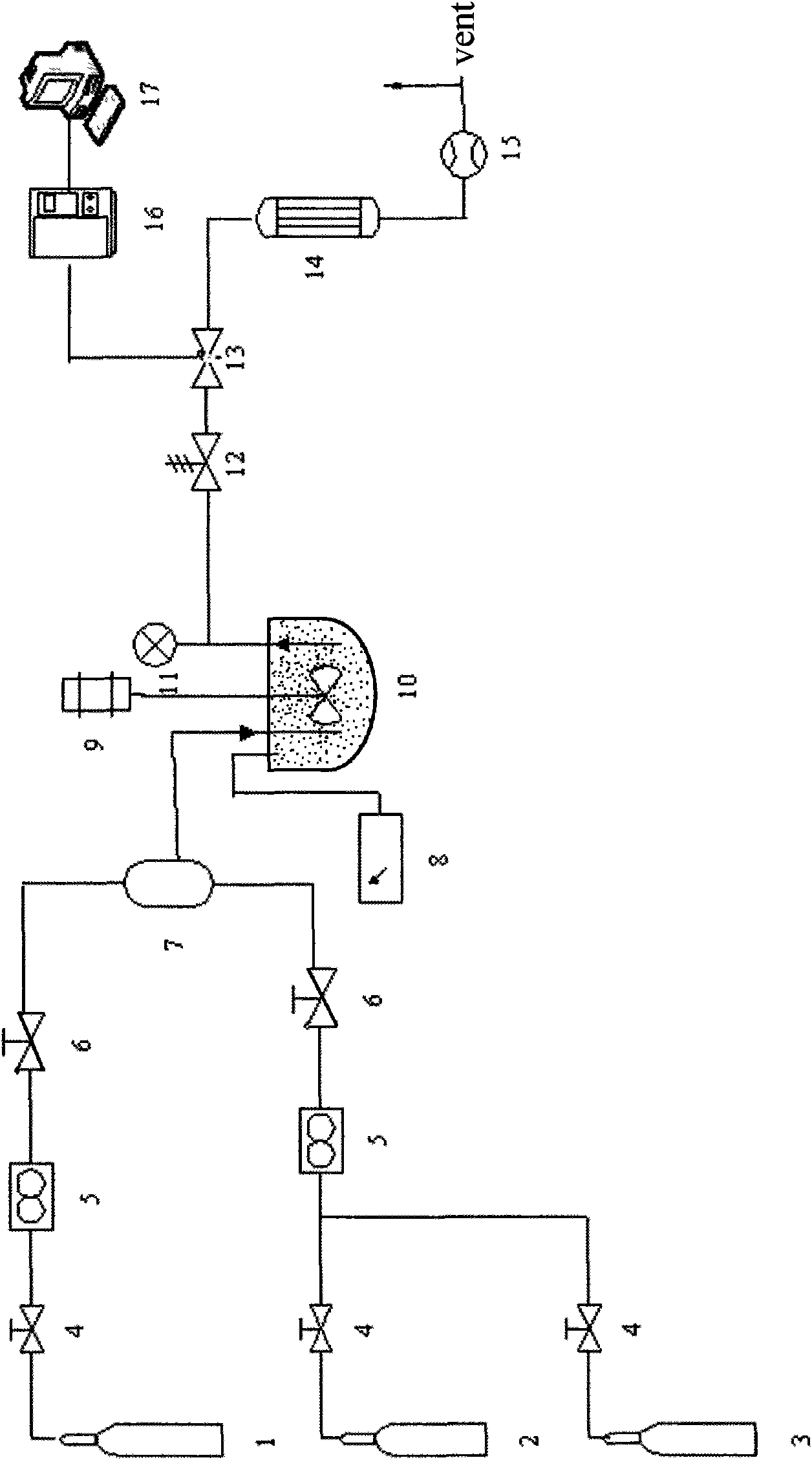

Method used

Image

Examples

Embodiment 1

[0025] (1) Implementation conditions

[0026] Choose CuO-ZnO-AL 2 O 3 -ZrO 2 / MgO-HZSM-5 is used as a catalyst, in which the MgO content is 1.0%, medical liquid paraffin is used as an inert liquid phase medium, and industrial CO 2 And H 2 It is the raw material gas for the reaction. The reactor is an electric heating permanent magnet rotating stirring autoclave. The operating temperature is 230℃, the operating pressure is 2.0Mpa, the stirring speed is 500r / min, and the hydrogen gas flow rate is 100Ncm. 3 ·Min -1 , CO 2 The gas flow rate is 300Ncm 3 ·Min -1 .

[0027] (2) Implementation results

[0028] CO 2 As a result of direct hydrogenation reaction, the selectivity of DME is 27%, the selectivity of methanol is 10%, and the selectivity of CO 2 The conversion rate was 12%.

Embodiment 2

[0030] (1) Implementation conditions

[0031] Choose CuO-ZnO-AL 2 O 3 -ZrO 2 / MgO-HZSM-5 is used as a catalyst, in which the MgO content is 2.0%, medical liquid paraffin is used as an inert liquid phase medium, and industrial CO 2 And H 2 It is the raw material gas for the reaction. The reactor is an electrically heated permanent magnet rotating stirring autoclave, with an operating temperature of 240°C, an operating pressure of 4.0Mpa, a stirring speed of 500r / min, and a hydrogen gas flow rate of 150Ncm. 3 ·Min -1 , CO 2 The gas flow rate is 450Ncm 3 ·Min -1 .

[0032] (2) Implementation results

[0033] CO 2 The selectivity of DME obtained from the direct reaction of hydrogenation is 45%, the selectivity of methanol is about 17%, and the selectivity of CO 2 The conversion rate is 25%.

Embodiment 3

[0035] (1) Implementation conditions

[0036] Choose CuO-ZnO-AL 2 O 3 -ZrO 2 / MgO-HZSM-5 is used as a catalyst, in which the MgO content is 10.0%, medical liquid paraffin is used as an inert liquid phase medium, and industrial CO 2 And H 2 It is the raw material gas for the reaction. The reactor is an electric heating permanent magnet rotating stirring autoclave, the operating temperature is 260℃, the operating pressure is 4.0Mpa, the stirring speed is 500r / min, and the hydrogen gas flow rate is 150Ncm. 3 ·Min -1 , CO 2 The gas flow rate is 450Ncm 3 ·Min -1 .

[0037] (2) Implementation results

[0038] CO 2 The selectivity of DME obtained by direct hydrogenation reaction is 32%, the selectivity of methanol is about 11%, and the selectivity of CO 2 The conversion rate is about 22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com