Crystal continuous producing device and method for continuously producing polysilicon by using same

A production equipment, polycrystalline silicon technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problem of continuous production of crystals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

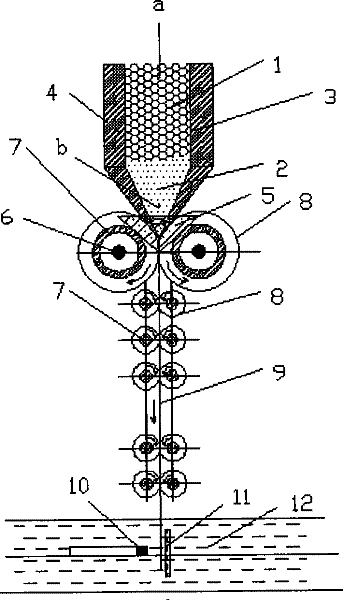

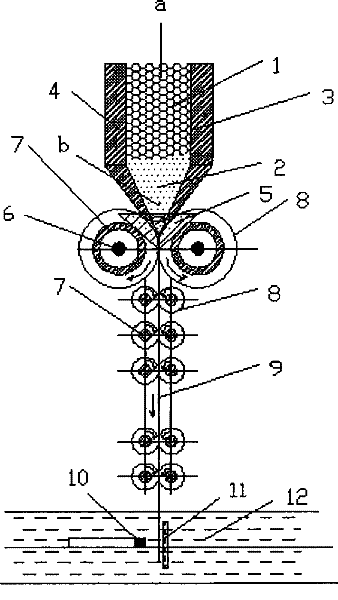

[0046] This example is used to illustrate the method for continuously producing polysilicon using the continuous crystal production equipment of the present invention.

[0047] In a helium atmosphere, use the figure 1 In the device shown, solar-grade silicon with a purity of 99.999% (5N-grade silicon produced by Tianjin Sunshine Metal Silicon Co., Ltd.) is used as solid silicon 1 and put into the built-in Si through the feed port a. 3 N 4 Layered quartz crucible (purchased from Hebei Jinglong Group's up and down transparent upper end is a 12-inch high-purity quartz crucible) 3, heated by a heater 4 arranged around the quartz crucible 3, so that the solid silicon 1 becomes Silicon 2 in the molten state, the silicon 2 in the molten state enters a guide roller pair 8 at the end of a temperature of 1430°C after coming out of the discharge port b of the quartz crucible 3 (the quartz guide roller has a layer of Si on its outside. 3 N 4 The ceramic layer, the axial length of the g...

Embodiment 2

[0049] This example is used to illustrate the method for continuously producing polysilicon using the continuous crystal production equipment of the present invention.

[0050] In a helium atmosphere, use the figure 1 In the device shown, solar-grade silicon with a purity of 99.9999% (6N-grade silicon produced by Tianjin Sunshine Metal Silicon Co., Ltd.) is used as solid silicon 1 and put into the built-in Si through the feed port a. 3 N 4 Layered quartz crucible (purchased from Hebei Jinglong Group's up and down transparent upper end is a 12-inch high-purity quartz crucible) 3, heated by a heater 4 arranged around the quartz crucible 3, so that the solid silicon 1 becomes Silicon 2 in the molten state, the silicon 2 in the molten state enters a guide roller pair 8 at the end of a temperature of 1470°C after coming out of the discharge port b of the quartz crucible 3 (the quartz guide roller has a layer of Si on its outside. 3 N 4 The ceramic layer, the axial length of the ...

Embodiment 3

[0052] This example is used to illustrate the method for continuously producing polysilicon using the continuous crystal production equipment of the present invention.

[0053] In a helium atmosphere, use the figure 1 In the device shown, solar-grade silicon with a purity of 99.9999% (6N-grade silicon produced by Tianjin Sunshine Metal Silicon Co., Ltd.) is used as solid silicon 1 and put into the built-in Si through the feed port a. 3 N 4 Layered quartz crucible (purchased from a 12-inch high-purity quartz crucible with a transparent upper end customized by Hebei Jinglong Group) 3, heated by a heater 4 arranged around the quartz crucible 3, so that the solid silicon 1 becomes It is silicon 2 in a molten state, and the silicon 2 in a molten state enters a guide roller pair 8 at the end of a temperature of 1500°C after coming out of the discharge port b of the quartz crucible 3 (the quartz guide roller has a layer of Si on its outside. 3 N 4 The ceramic layer, the axial leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com