Gas absorbent for reducing gas concentration

A gas concentration and absorbent technology, applied in the field of harmful gas absorption materials, can solve problems such as complex preparation methods, achieve the effects of improving solubility, ensuring safety, and eliminating hidden dangers of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a gas absorbent for reducing gas concentration, the absorbent is a liquid mixed micellar solution composed of an ionic surfactant, a nonionic surfactant and water, by weight percentage, wherein The total weight of the ionic surfactant and the nonionic surfactant accounts for 10-20% of the total weight of the absorbent, and the rest is water. Wherein, the ionic surfactant is sodium lauryl sulfate. The nonionic surfactant is any one of alkylphenol polyoxyethylene ether (Triton x-100), Tween 80, and castor oil polyoxyethylene ether (EL-20).

[0030] In the above-mentioned absorbent, when the ionic surfactant adopts sodium lauryl sulfate, and the nonionic surfactant adopts alkylphenol polyoxyethylene ether (triton x-100), sodium lauryl sulfate The weight ratio of alkylphenol polyoxyethylene ether (Triton x-100) in the absorbent is preferably 1:3.

[0031] In the above-mentioned absorbent, when the ionic surfactant adopts sodium lauryl sulfate, and...

Embodiment 2

[0037] The gas absorbent for reducing the gas concentration provided in this example is specifically made by mixing ionic surfactants, nonionic surfactants, and water to form a mixed micellar solution, wherein the ionic surfactant Adopt sodium lauryl sulfate, its consumption is 5%, non-ionic surface active agent adopts alkylphenol polyoxyethylene ether (triton x-100), its consumption is 15%, other composition is water.

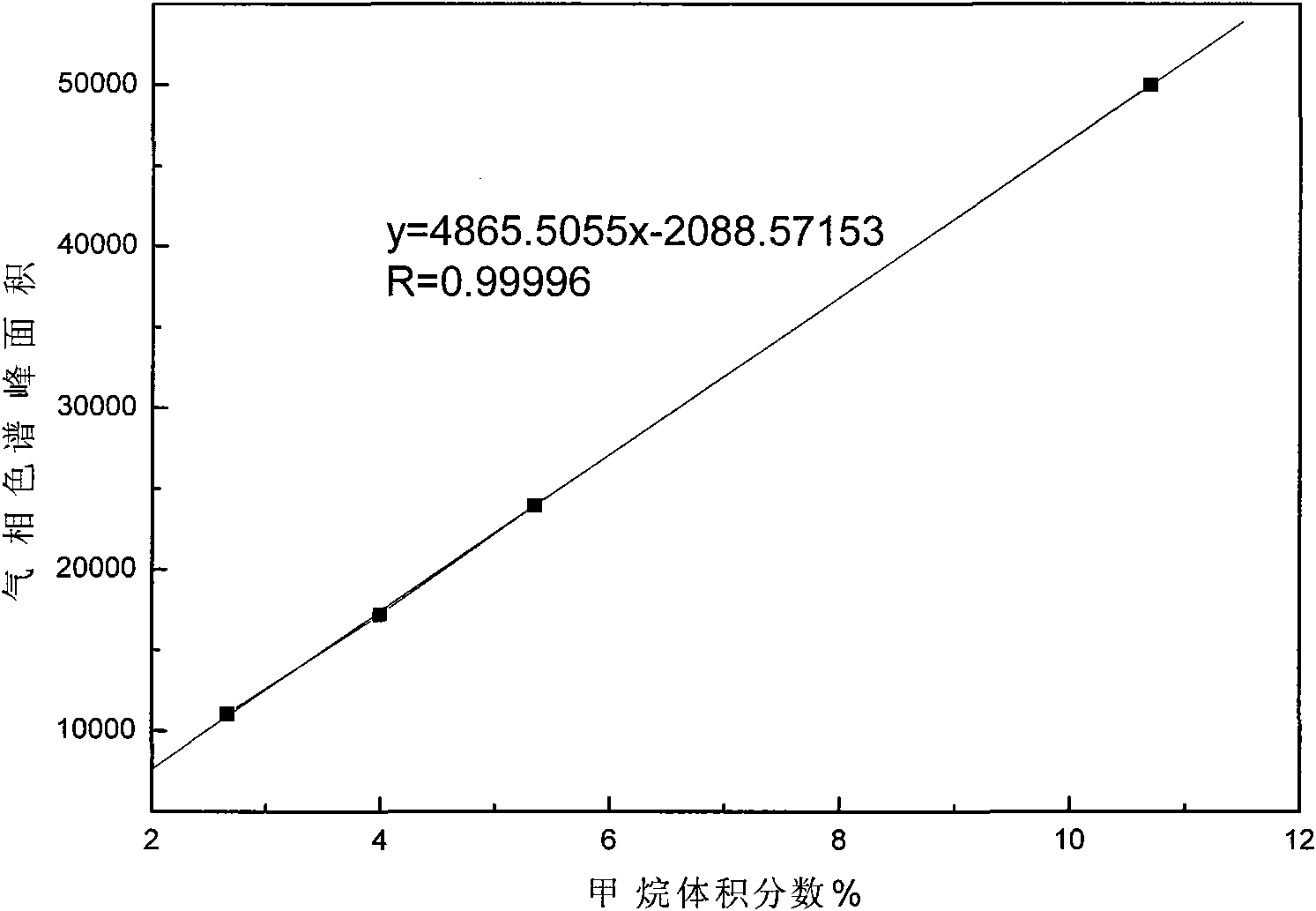

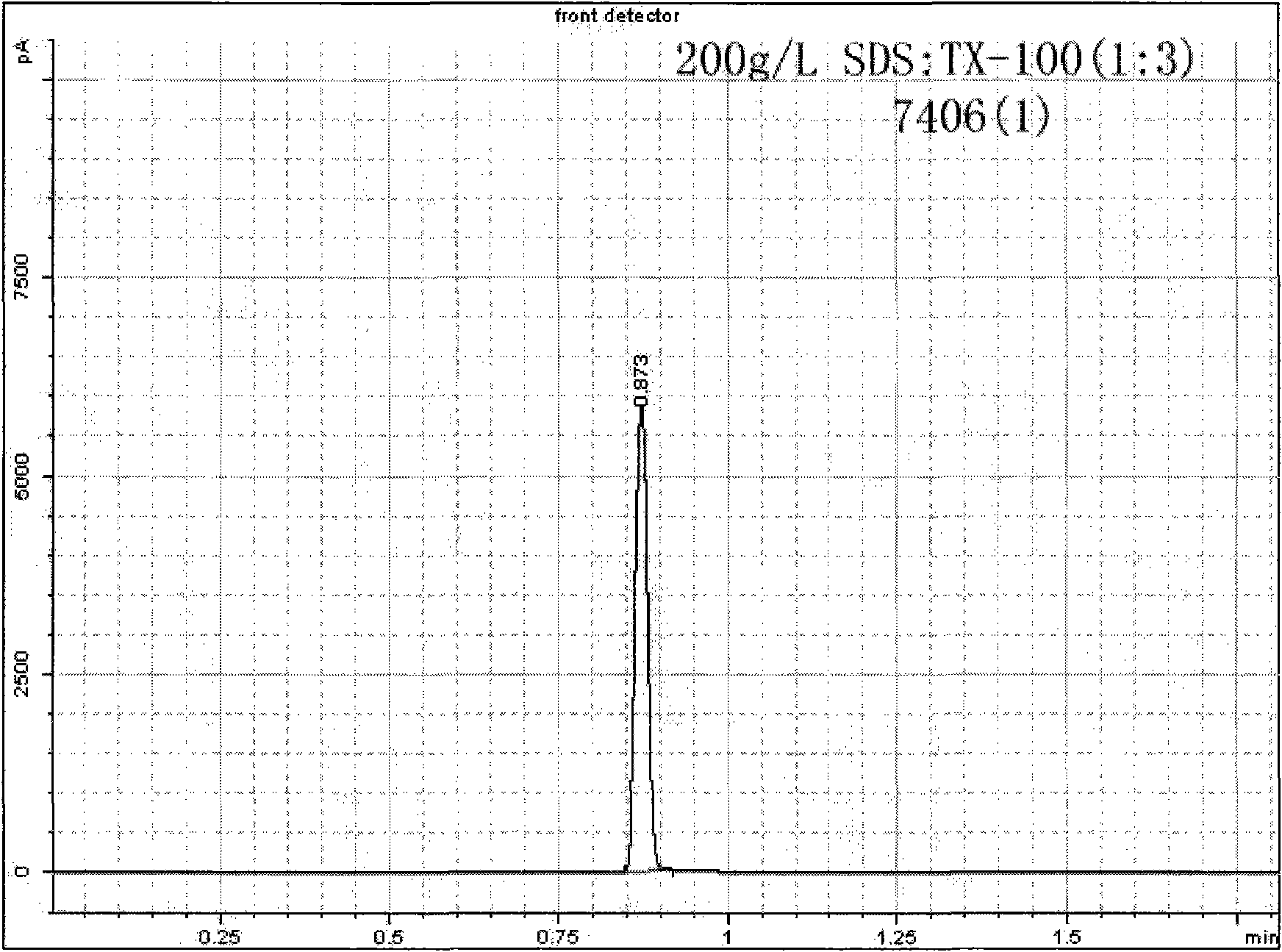

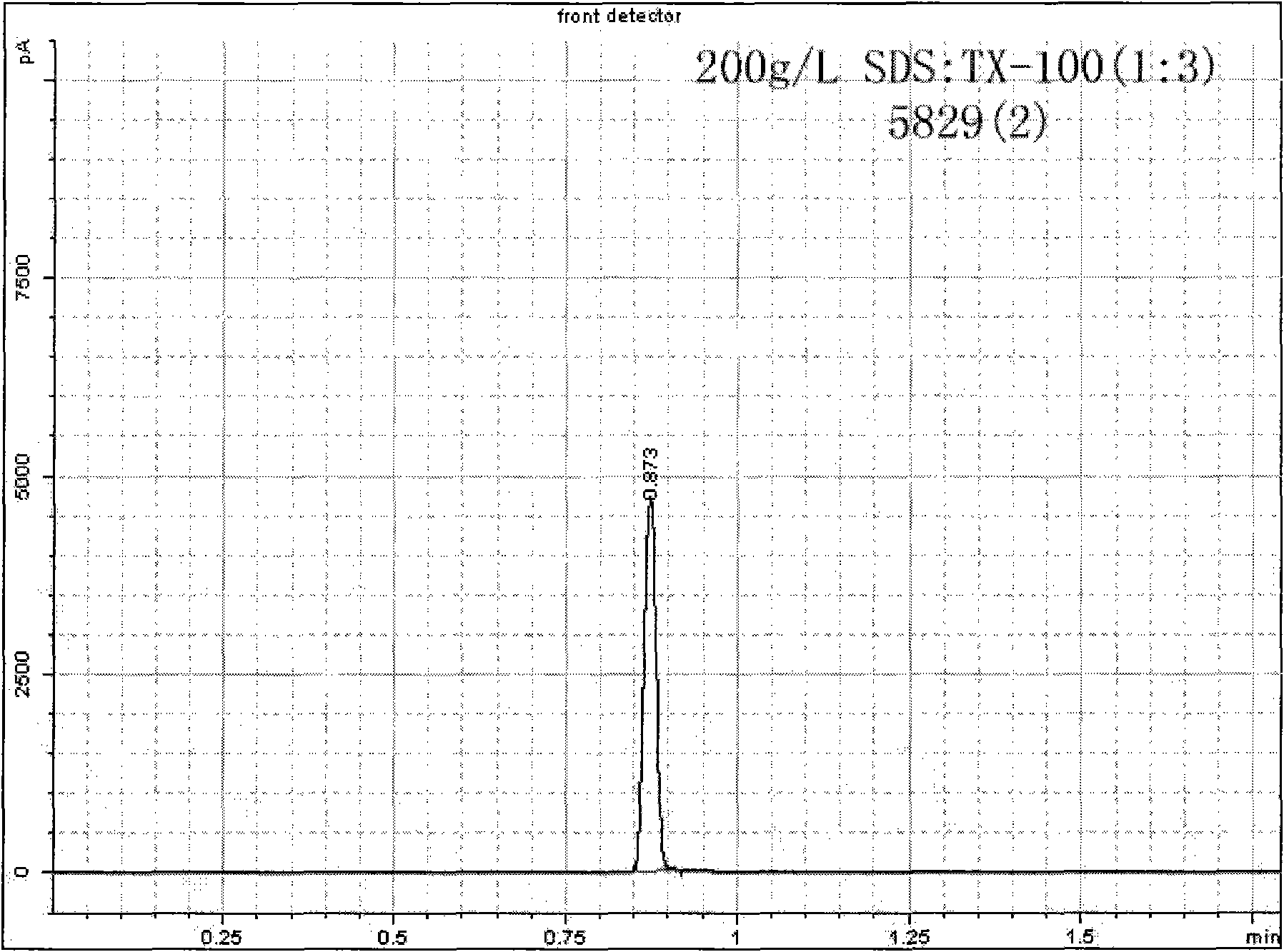

[0038] Gas absorbent in the present embodiment, when the concentration of sodium lauryl sulfate in absorbent as ionic surfactant is 5%, and as nonionic surfactant Triton x- When the concentration of 100 in the absorbent is 15%, the absorption liquid obtained after the absorbent of the composition absorbs methane carries out headspace gas chromatographic analysis, Figure 2a ~ Figure 2cIt is the gas chromatogram obtained after three headspace extraction gas chromatography analyzes after the absorbent absorbs methane (the peak area calculated according to the th...

Embodiment 3

[0040] The gas absorbent for reducing the gas concentration provided in this example is specifically formed by mixing ionic surfactants, amphoteric surfactants and water to form a liquid mixed micellar solution, wherein the ionic surfactants are Sodium lauryl sulfate, its consumption is 15%, nonionic surfactant is Tween 80, and its consumption is 5%, and other components are water.

[0041] The gas absorbent in this embodiment, after testing, when the concentration of sodium lauryl sulfate in the absorbent as the ionic surfactant is 15%, and Tween 80 as the ionic surfactant is added to the absorbent When the concentration in is 5%, the absorbing liquid obtained after the absorbent absorbing methane is carried out headspace gas chromatographic analysis, Figure 3a ~ Figure 3c It is the gas chromatogram obtained after carrying out three headspace extraction gas chromatography analysis after the absorbent absorbs methane (the peak area calculated according to the three headspace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com