Process for treating methylsulfonic acid plating solution generated in cold mill electrolytic tinning unit

A technology of electro-tinning unit and methanesulfonic acid, which is applied in the field of iron and steel, can solve the problems of poor treatment effect and achieve the effect of solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

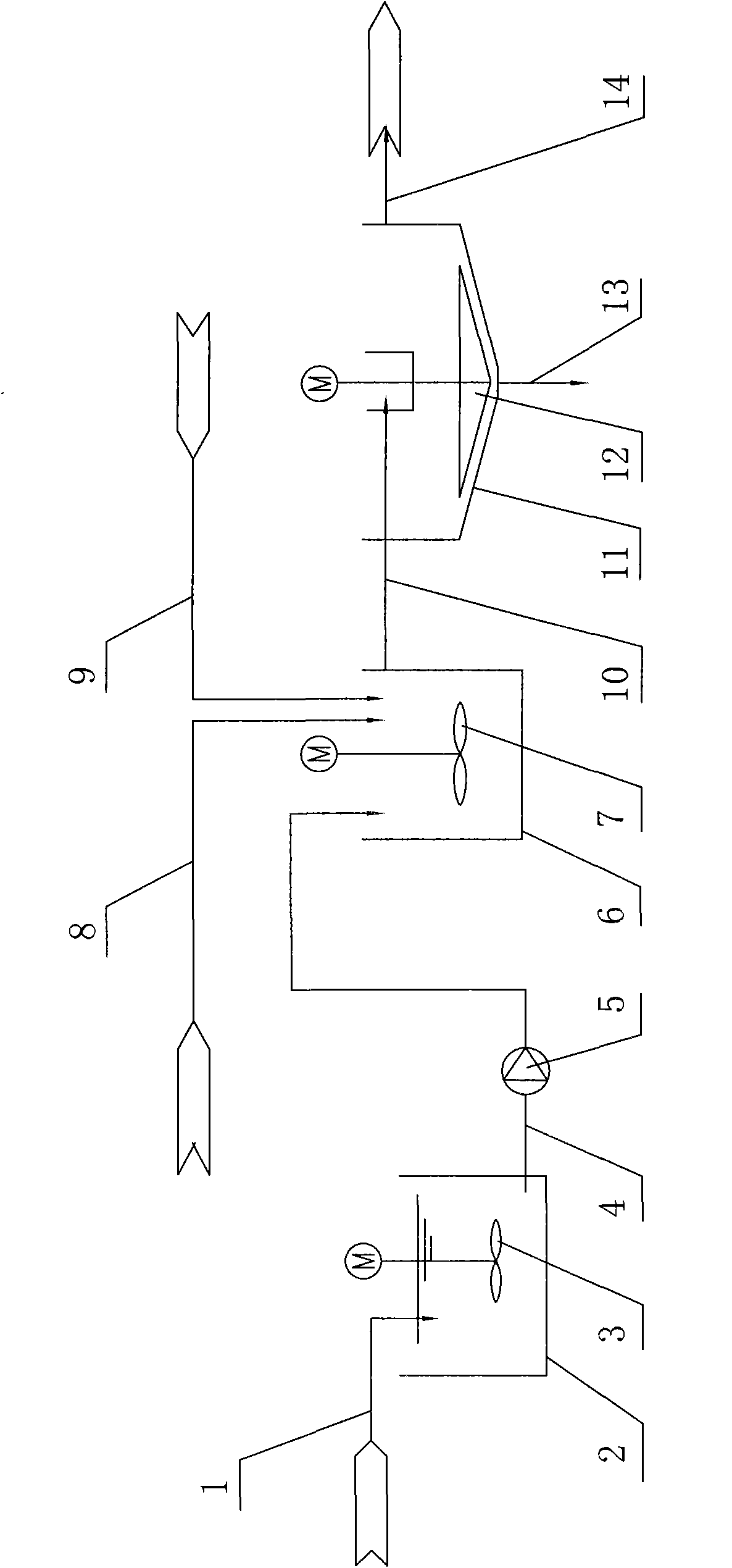

Image

Examples

Embodiment 1

[0013] The treatment process of the methanesulfonic acid plating solution that the cold-rolled electrotin plating unit produces, it comprises the steps:

[0014] 1) The methanesulfonic acid plating solution (MSA) wastewater produced by the cold-rolled tinning unit enters a separate wastewater regulating tank, and the mixer is set to continuously stir (the residence time of the wastewater in the wastewater regulating tank is not limited); then the wastewater is lifted by a pump into the reaction pool;

[0015] 2) Add polyacrylamide (PAM) and Ca(OH) to the reaction pool 2 , to carry out neutralization and flocculation reactions, so that the pH in the wastewater is raised from 1 to 2 to 8, and Ca(OH) 2 The dosage of polyacrylamide (PAM) is determined according to the pH. The dosage of polyacrylamide (PAM) is 5mg / L (according to the addition of 5mg polyacrylamide per liter of wastewater in the reaction tank). for 12 minutes; then sent to the sedimentation tank;

[0016] 3) Stay...

Embodiment 2

[0019] The treatment process of the methanesulfonic acid plating solution that the cold-rolled electrotin plating unit produces, it comprises the steps:

[0020] 1) The methanesulfonic acid plating solution (MSA) wastewater produced by the cold-rolled tinning unit enters a separate wastewater regulating tank, and the mixer is set to continuously stir (the residence time of the wastewater in the wastewater regulating tank is not limited); then the wastewater is lifted by a pump into the reaction pool;

[0021] 2) Add polyacrylamide (PAM) and Ca(OH) to the reaction pool 2 , to carry out neutralization and flocculation reactions, so that the pH in the wastewater is raised to 6, Ca(OH) 2 The dosage of polyacrylamide (PAM) is determined according to the pH. The dosage of polyacrylamide (PAM) is 5mg / L (according to the addition of 5mg polyacrylamide per liter of wastewater in the reaction tank). for 10 minutes; then sent to the sedimentation tank;

[0022] 3) Stay in the sediment...

Embodiment 3

[0024] The treatment process of the methanesulfonic acid plating solution that the cold-rolled electrotin plating unit produces, it comprises the steps:

[0025] 1) The methanesulfonic acid plating solution (MSA) wastewater produced by the cold-rolled tinning unit enters a separate wastewater regulating tank, and the mixer is set to continuously stir (the residence time of the wastewater in the wastewater regulating tank is not limited); then the wastewater is lifted by a pump into the reaction pool;

[0026] 2) Add polyacrylamide (PAM) and Ca(OH) to the reaction pool 2 , to carry out neutralization and flocculation reactions, so that the pH in the wastewater is raised to 9, Ca(OH) 2 The dosage of polyacrylamide (PAM) is determined according to the pH. The dosage of polyacrylamide (PAM) is 5mg / L (according to the addition of 5mg polyacrylamide per liter of wastewater in the reaction tank). for 15 minutes; then sent to the sedimentation tank;

[0027] 3) Stay in the sediment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com