Nuclear power 1E-level K3-type thermal shrinkage material and preparation process

A technology of heat shrinkage and nuclear power, applied in the field of cable accessories manufacturing, to achieve the effect of improving flame retardancy and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 150g POE (model 8999), 355g EVA (model 18-3), 10g antioxidant AT-10, 200g aluminum hydroxide after coupling treatment, 115g magnesium hydroxide after coupling treatment, 35g after coupling treatment Nitrogen-based flame retardant (FR-PN), 15g of EPDM 4045 was added to the internal mixer, mixed for 20 minutes at 135°C, and then 20g of lubricant stearic acid, 15ml of sensitizer (TMPTA) and 12ml tin methyl mercaptide heat stabilizer, knead for 10 minutes. Obtain the masterbatch of 1E grade K3 heat-shrinkable material, press the material with a hydraulic press to prepare samples, and then irradiate 150KGy with an electron accelerator to obtain nuclear power 1E grade K3 heat-shrinkable material 1 # .

Embodiment 2

[0022] Mix 150g POE (model 8999), 350g EVA (model 14-2), 10g antioxidant 7910, 175g aluminum hydroxide after coupling treatment, 100g magnesium hydroxide after coupling treatment, 75g nitrogen-based barrier after coupling treatment Fuel agent (FR-PN), 15g of EPDM rubber into the internal mixer, mixing at 135°C for 20 minutes, then add 20g of lubricant zinc stearate, 10ml of sensitizer (TMPTA) and 12ml of methyl sulfide The tin alcohol heat stabilizer was kneaded for 10 minutes. Obtain the masterbatch of 1E grade K3 heat-shrinkable material, press the material with a hydraulic press to prepare samples, and then irradiate 170KGy with an electron accelerator to obtain nuclear power 1E grade K3 heat-shrinkable material 2 # .

Embodiment 3

[0024] 160g POE8999, 350EVA1405, 10g antioxidant 1010, 175g aluminum hydroxide after coupling treatment, 125g magnesium hydroxide after coupling treatment, 50g nitrogen-based flame retardant (FR-PN) after coupling treatment, 15g silicon Rubber and 12ml of tin mercaptide heat stabilizer were added to the internal mixer, and the mixture was mixed for 20 minutes at 135°C, then 20g of lubricant flyaway and 10ml of sensitizer (TMPTA) were added, and kneaded for 10 minutes. Obtain the masterbatch of 1E grade K3 heat-shrinkable material, press the material with a hydraulic press to prepare samples, and then irradiate 170KGy with an electron accelerator to obtain nuclear power 1E grade K3 heat-shrinkable material 3 # .

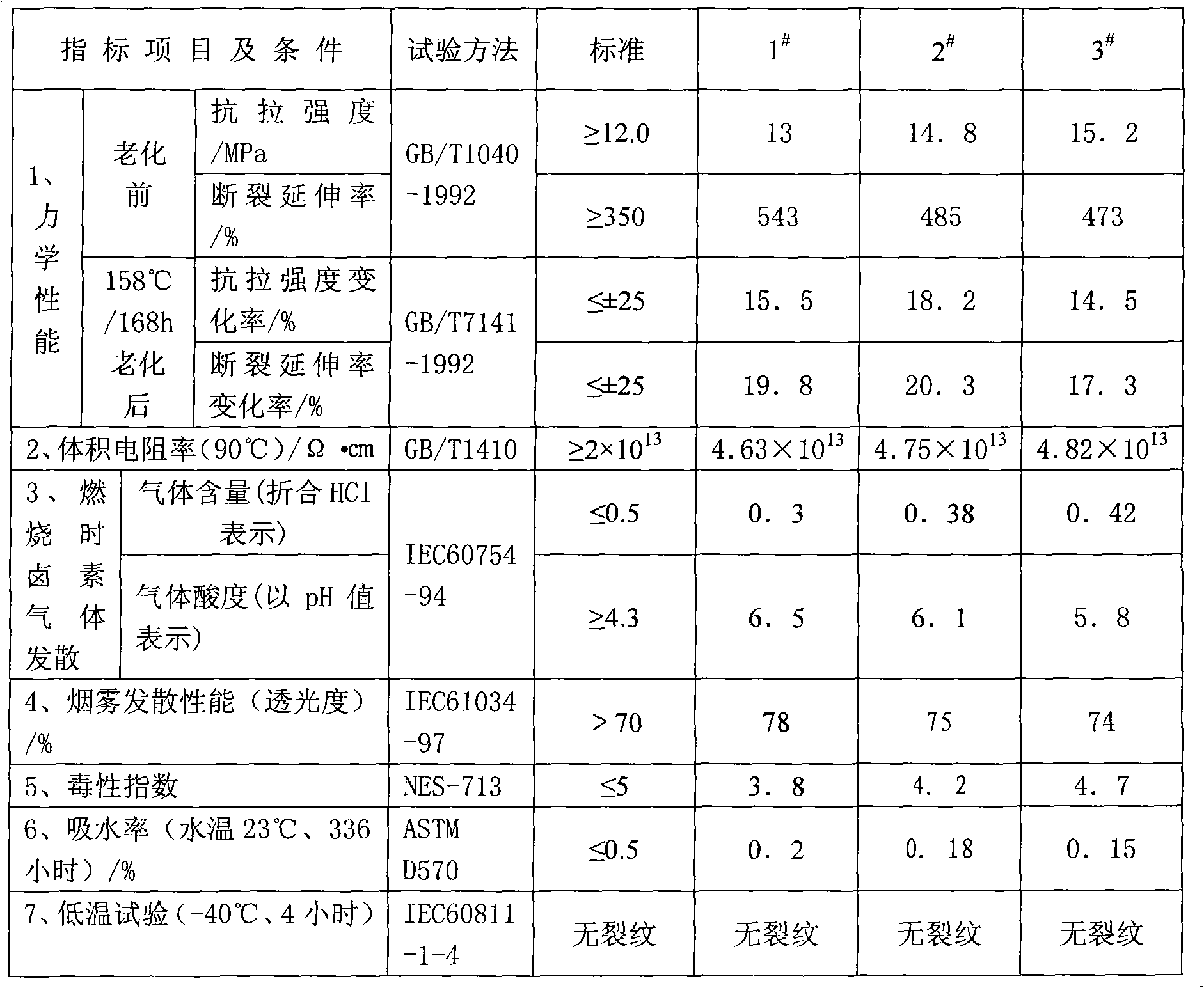

[0025] The obtained sample performance index:

[0026] 1. Material thermal life evaluation:

[0027] 1) Thermal life evaluation method:

[0028] According to the IEC60216 standard and the IEEE383-2003 standard, the mathematical model recommended for the accelerated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com