Microwave-assisted coal extraction method through ethanol

A microwave-assisted, ethanol technology, applied in the petroleum industry, solid fuel, fuel and other directions, can solve the problems of long extraction time, low efficiency, high energy consumption, etc., and achieve a short extraction time, high efficiency and high economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

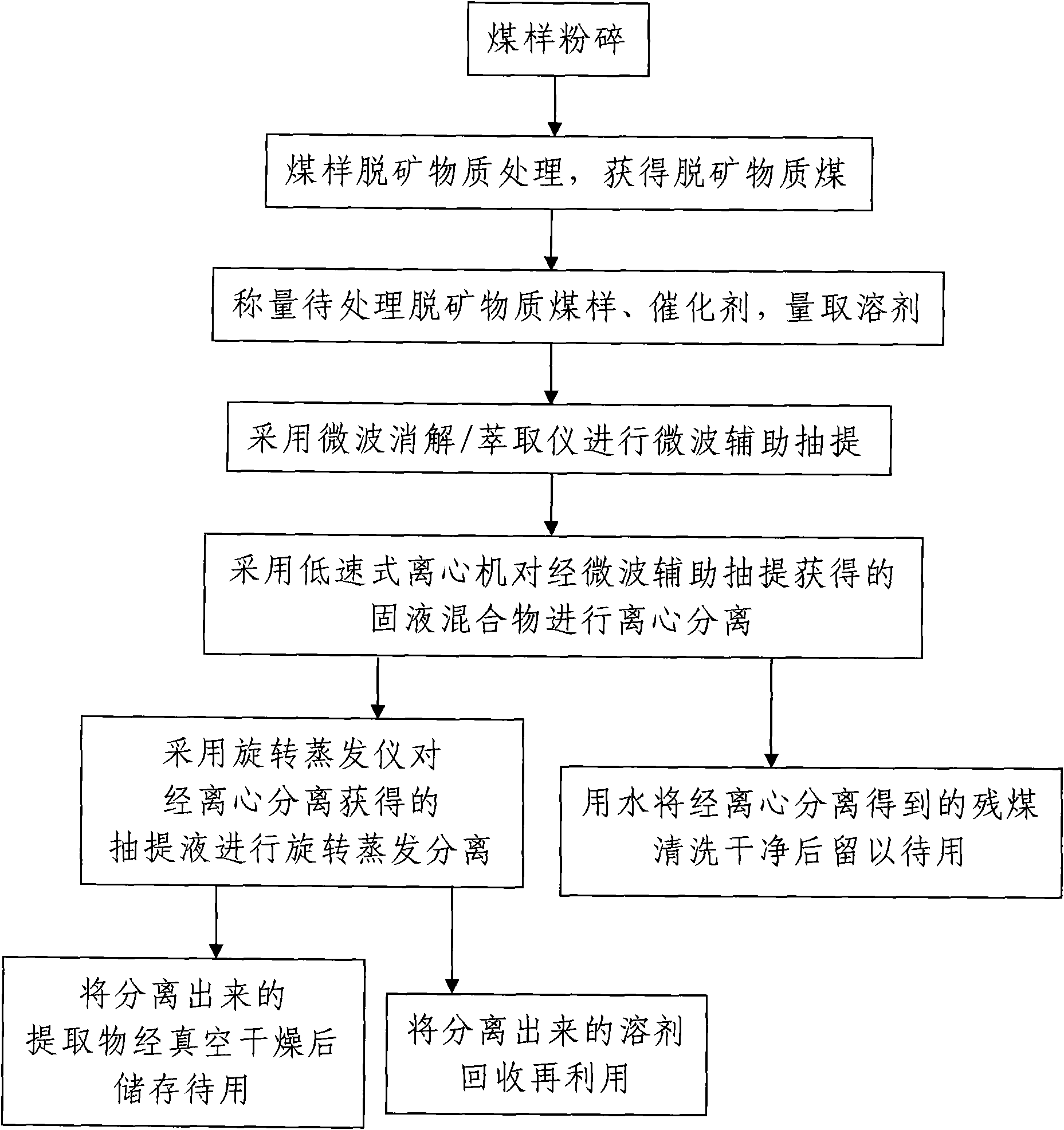

[0035] Such as figure 1 As shown, the microwave-assisted ethanol extraction method of coal of the present invention comprises the following steps:

[0036] Step 1. Coal sample crushing: use a pulverizer to crush the coal sample to be treated and dry it for later use, and the crushed particle size is 150-75 μm. The coal sample to be processed is long-flame coal, specifically long-flame coal that meets the standard GB5751-86 of "China Coal Classification".

[0037] In this embodiment, the coal sample to be processed is specifically Shenfu coal. In actual operation, the coal sample to be treated is pulverized and dried, and stored in a brown bottle for later use.

[0038] Step 2, coal sample demineralization treatment: the pulverized coal sample is subjected to conventional demineralization treatment and dried to obtain a demineralized coal sample. The drying described in this step is carried out in a vacuum drying oven, and the drying temperature is 105±5°C, and the drying ti...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that the coal sample to be treated in Step 1 is specifically Tongchuan coal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com