Method using ion nitriding technology to prepare solar energy absorbing coating

A technology of solar energy absorption and ion nitridation, which is applied in the field of preparation of solar energy absorption coatings, can solve the problems of expensive operation, complex equipment, slow hot start, etc., and achieve the effects of simplifying the process, reducing production costs and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

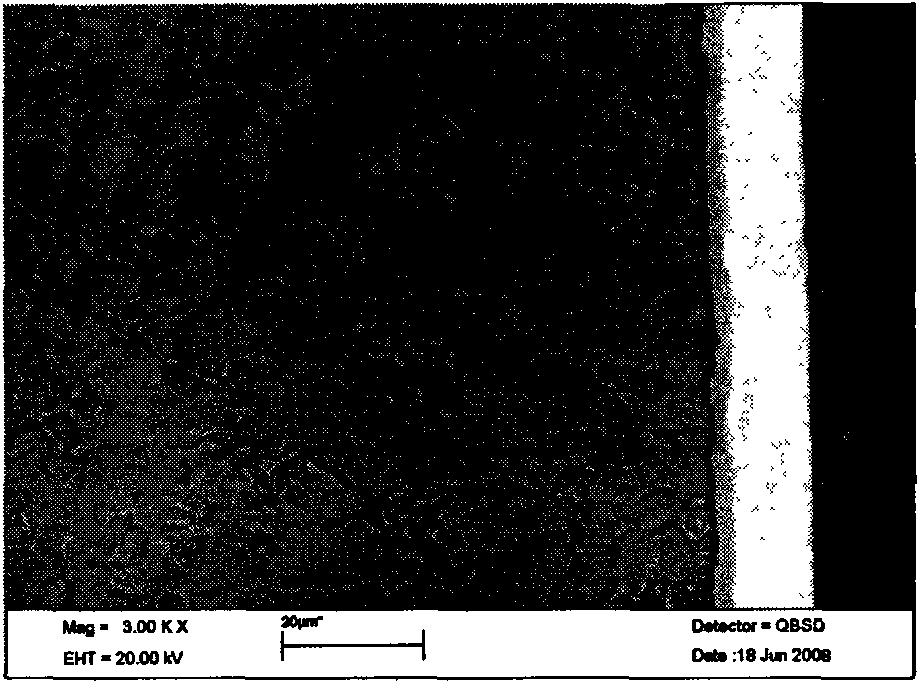

Image

Examples

Embodiment 1

[0024] 1. First, use chemical treatment to clean the surface of the aluminum alloy tube to make it chemically react with oil, dirt, rust, scale, and oxide film to form soluble substances, so that the surface of the aluminum alloy tube to be treated is smooth and clean. Specific steps are as follows:

[0025] (1) Etching the aluminum alloy pipe with a NaOH solution with a concentration of 8%-10% and a solution temperature of 40°C-60°C for 10-15 minutes;

[0026] (2) Rinse with cold water for about 2 minutes;

[0027] (3) neutralize in a dilute nitric acid solution with a volume fraction of 30%, so that the surface of the aluminum alloy tube is smooth and clean;

[0028] (4) Rinse with hot water at 50°C to 60°C for 2 to 3 minutes, and brush with a hard brush;

[0029] (5) Dry it in a drying oven at 100°C to 150°C for about 30 minutes, and set it aside.

[0030] 2. Ion nitriding treatment on the surface of aluminum alloy tube

[0031] 1. Furnace loading: seal both ends of the...

Embodiment 2

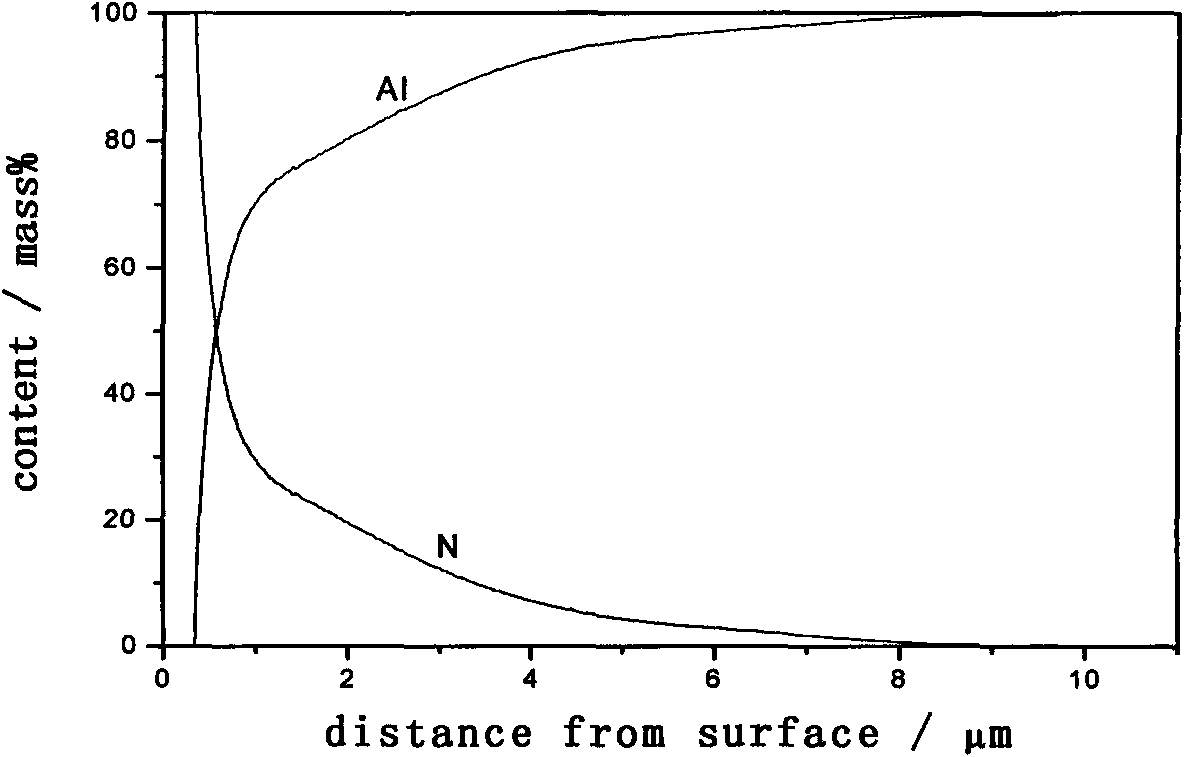

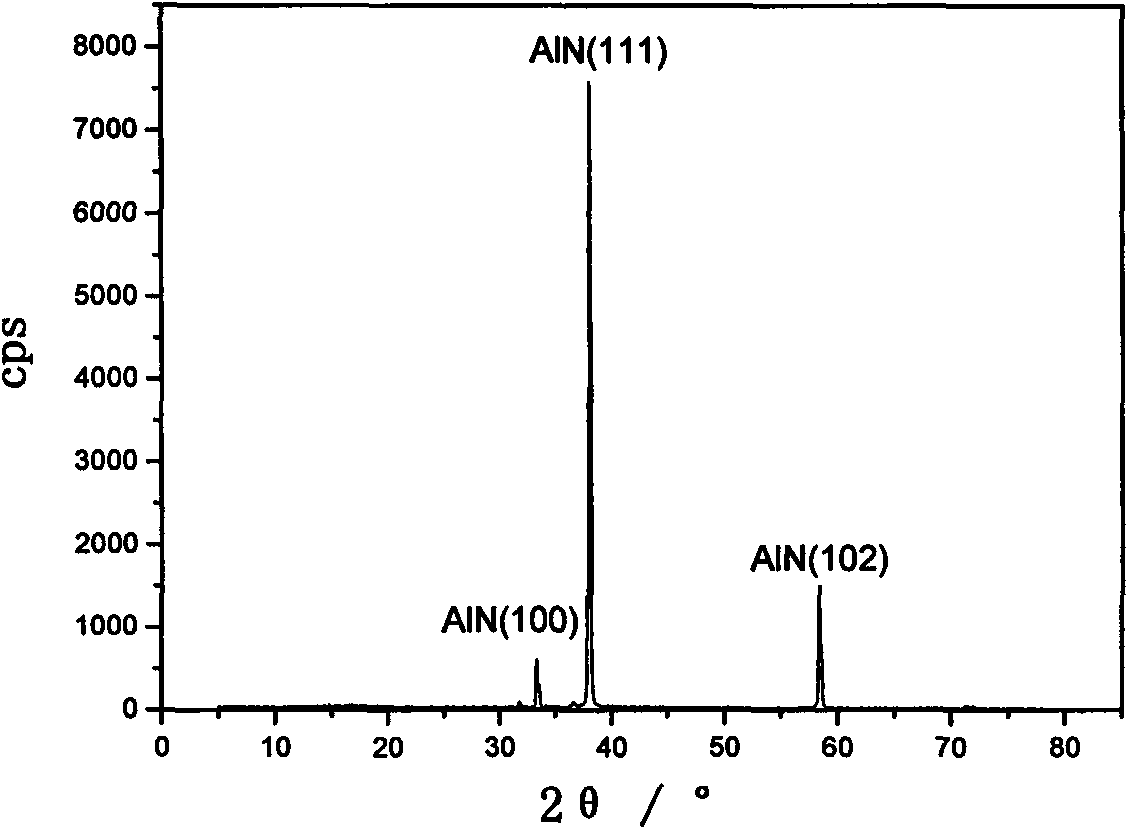

[0037] According to the method of Example 1, a net-like sponge-type porous graphite source was added in the ion nitriding furnace, and ion nitriding treatment was performed on the surface of the aluminum alloy tube. When the temperature rises to 350°C, adjust the graphite electrode voltage to 400V, carry out ion nitriding, and keep the temperature for 2 hours. After slowly cooling out of the furnace, a gradient AlN-Al composition gradient is formed on the surface of the aluminum alloy tube, which is the solar energy absorbing coating.

[0038] The light-to-heat conversion efficiency of the aluminum nitride coating prepared in this example without a vacuum insulation layer is 92.4% of that of the existing solar vacuum heat collecting tube finished product.

Embodiment 3

[0040]According to the method of Example 1, a grid-shaped sponge-type porous graphite electrode was added in the ion nitriding furnace, and ion nitriding treatment was performed on the surface of the aluminum alloy tube. After sputtering and cleaning at a pressure of 40Pa and a voltage of 550V, 99.99% high-purity nitrogen is introduced, the volume ratio of argon and nitrogen is controlled to be 0.4, the pressure is increased to 400Pa, the power supply voltage is adjusted to 700V, and the graphite electrode voltage is adjusted. 500V, keep the temperature at 450°C, perform ion nitriding on the surface of the aluminum alloy tube, keep it warm for 1 hour, and form a gradient AlN-Al with a gradient change on the surface of the aluminum alloy tube, which is the solar absorbing coating.

[0041] The light-to-heat conversion efficiency of the aluminum nitride coating prepared in this example without a vacuum insulation layer is 91.6% of the finished product of the existing solar vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com