K-waveband dielectric disk-loaded circular waveguide feed filter

A technology of electric filter and dielectric film, which is applied in the field of isolated wave-transparent feeder, can solve problems affecting system performance and cannot meet the mechanical isolation requirements of radar antennas, and achieve low insertion loss and simple and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

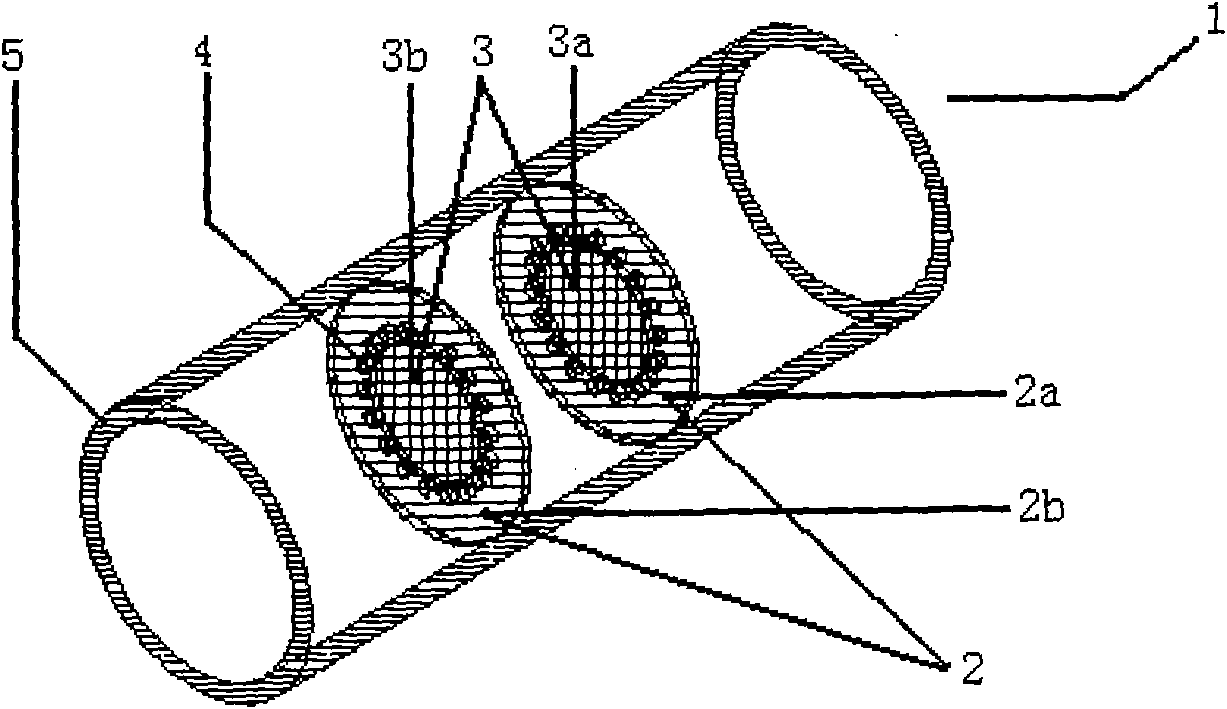

[0034] according to image 3Shown is a preferred embodiment of a K-band dielectric diaphragm-loaded circular waveguide feed filter 1 based on the present invention. In this preferred embodiment, the working center frequency is 24GHz and the bandwidth is 1.5GHz. The inner radius of the cylindrical metal cavity 5 is 4.3mm, the radius of the dielectric diaphragms 3a and 3b is 2.35mm, the distance between the two dielectric diaphragms 3a and 3b is 7mm, and the diameter of the metallized via hole 4 is 0.5mm. The distance between the edge of the metallized via hole 4 and the edge of the dielectric diaphragm 3 is 0.25 mm. In the invention, the diameter of the metallized via hole 4 can be as small as 0.2 mm. The metallized via holes 4 have an angular interval of 15 degrees and are uniformly arranged along the edge of the dielectric diaphragm 3 . The medium used to manufacture the microwave substrate 2 of the dielectric diaphragm 3 is alumina with a purity of 99% and a dielectric co...

Embodiment 2

[0036] according to image 3 Shown is another preferred embodiment of a K-band dielectric diaphragm-loaded circular waveguide feed filter 1 based on the present invention. In this preferred embodiment, the working center frequency is 20GHz and the bandwidth is 1.1GHz. The inner radius of the circular waveguide 5 is 4.7mm, the radius of the dielectric diaphragms 3a and 3b is 2.8mm, the distance between the two dielectric diaphragms 3a and 3b is 7.8mm, and the diameter of the metallized via hole 4 is 0.5mm. The distance between the edge of the metallized via hole 4 and the edge of the dielectric diaphragm 3 is 0.25 mm. In the invention, the diameter of the metallized via hole 4 can be as small as 0.2mm. The metallized via holes 4 have an angular interval of 15 degrees and are uniformly arranged along the edge of the dielectric diaphragm 3 . The medium used to manufacture the microwave substrate 2 of the dielectric diaphragm 3 is alumina with a purity of 99% and a dielectric c...

Embodiment 3

[0038] according to image 3 Shown is another preferred embodiment of a K-band dielectric diaphragm-loaded circular waveguide feed filter 1 based on the present invention. In this preferred embodiment, the working center frequency is 22GHz and the bandwidth is 1.3GHz. The inner radius of the circular waveguide 5 is 4.7mm, the radius of the dielectric diaphragms 3a and 3b is 2.8mm, the distance between the two dielectric diaphragms 3a and 3b is 8.3mm, and the diameter of the metallized via hole 4 is 0.6mm. The distance between the edge of the metallized via hole 4 and the edge of the dielectric diaphragm 3 is 0.25mm. In the invention, the diameter of the metallized via hole 4 can be as small as 0.2mm. The metallized via holes 4 have an angular interval of 15 degrees and are uniformly arranged along the edge of the dielectric diaphragm 3 . The medium used to manufacture the microwave substrate 2 of the dielectric diaphragm 3 is beryllium oxide with a purity of 99.5% and a die...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com