Three-band pulsing laser

A pulsed laser and pulsed laser technology, applied in the laser field, can solve the problems of inability to be used for fine micromachining, low single pulse energy, low repetition frequency, etc., and achieve compact overall cavity design, high frequency doubling conversion efficiency, and reduce device damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

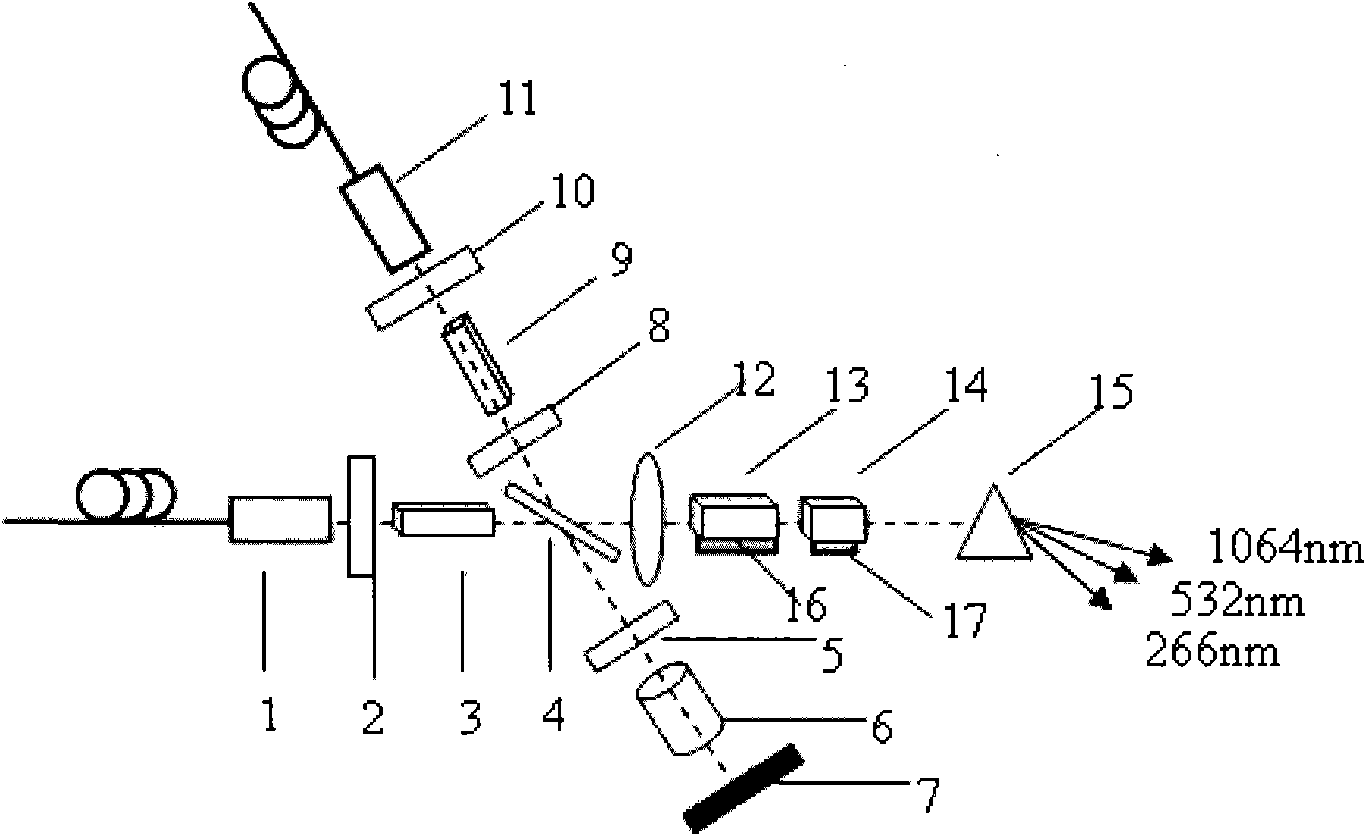

[0032] like figure 1 As shown, the three-band pulsed laser according to Embodiment 1 of the present invention includes: a pulsed laser seed source, a laser amplification device and a three-band output device.

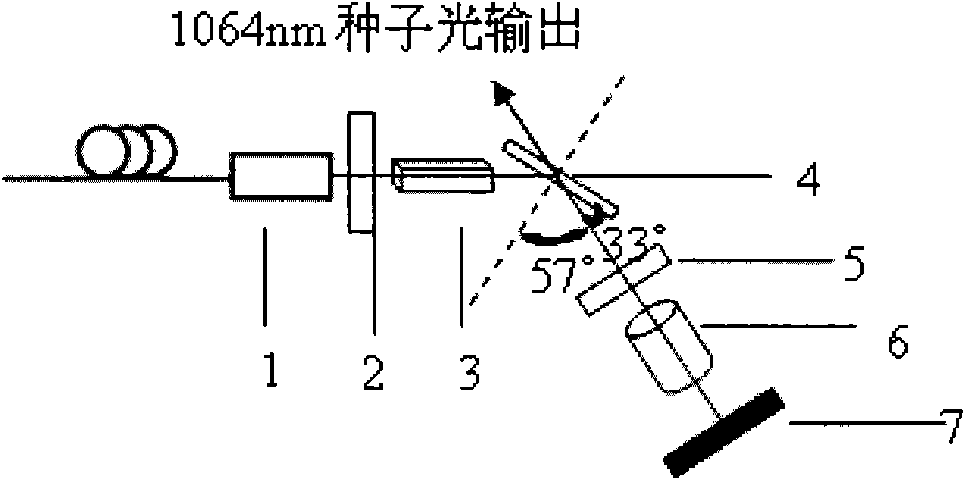

[0033] The pulsed laser seed source includes a first LD (laser diode) pump source 1, a first plane mirror 2, a first laser crystal 3, a polarizer 4, a first 1 / 4 wave plate 5, an electro-optic Q switch 6, and a second plane mirror 7 (total reflection plane mirror). The first LD pumping source 1 comprises a pulse LD, an optical fiber and an optical fiber coupled output head ( figure 1 The pulse LD is not shown in the figure, only the optical fiber and the fiber coupling output head that lead out the pump light emitted by the pulse LD are shown, and the fiber coupling output head can shape the pump light), the light output surface of the fiber coupling output head Anti-reflection film of pump light wavelength (808nm) is plated; one side of the first plane mirror 2 facing...

Embodiment 2

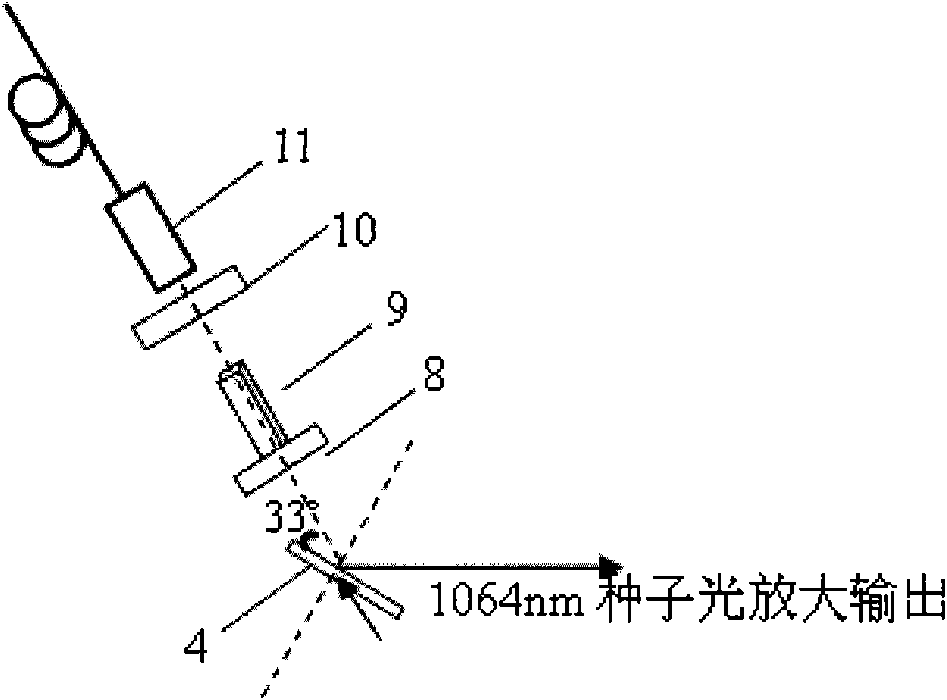

[0041] Figure 5 Represent the schematic diagram of the pulsed laser according to embodiment 2 of the present invention, its structure is similar to embodiment 1, only the laser amplifying device in the present embodiment is a one-way amplifying device, has omitted the second 1 / 4 wave plate 8, and has adopted A third plane mirror 18 is used instead of the third plane mirror 10 in Embodiment 1. The angle between the third flat mirror 18 and the horizontal direction is approximately 45°, which is placed between the second LD pump source 11 and the second laser crystal 9 of the laser amplifying device, for receiving the seed laser and reflecting it to the second Laser crystal 9; and its one side facing the polarizer 4 is coated with an anti-reflection film for the wavelength of pump light, and the other side is coated with an anti-reflection film for the wavelength of pump light and a high-reflection film for the wavelength of the seed light (that is, the fundamental frequency la...

Embodiment 3

[0044] Image 6 A schematic diagram showing a pulsed laser according to Example 3 of the present invention. As shown in the figure, its structure is substantially the same as that of Embodiment 2, except that the axial direction of the laser amplifying device forms an included angle of 33° with the polarizer 4, and the third plane mirror 18 forms an included angle of 57° with the axis of the three-band output device, so that The seed laser light emitted from the polarizer 4 is amplified by the second laser crystal 9 and then reflected by the third plane mirror 18 to the focusing mirror 12 .

[0045] The invention injects seed light into the laser amplifying device, thereby reducing damage to the laser seed source part (not amplifying in the cavity of the pulse laser seed source) while realizing high energy output. The frequency doubling conversion efficiency is directly related to the power density of the fundamental frequency laser to a certain extent, and the pulse width of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com