System and process for coal powder preparation

A pulverized coal preparation and process technology, which is applied in the pulverized coal preparation system and process field, can solve the problems of inability to meet the requirements of fine pulverized coal particle size, low efficiency of pulverizing system, large coal pulverized particle size, etc., and achieve simple structure and improved grinding Efficiency and floor space savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

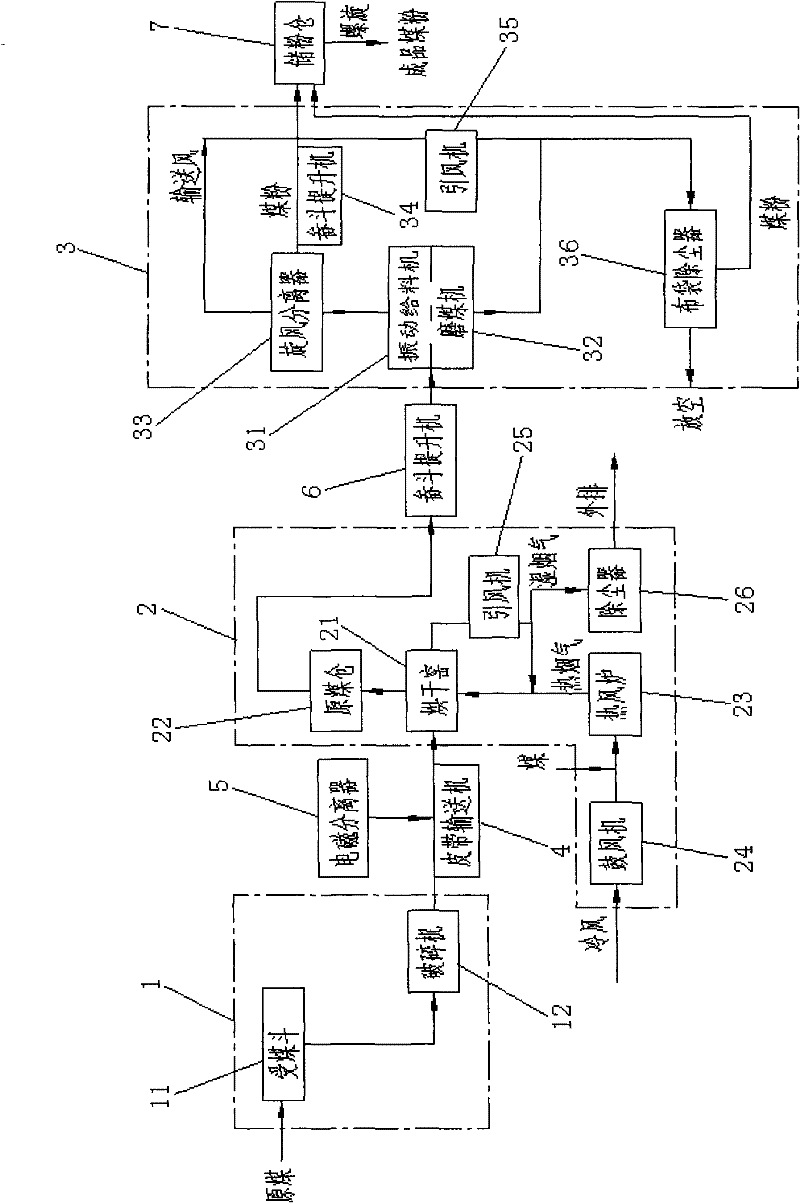

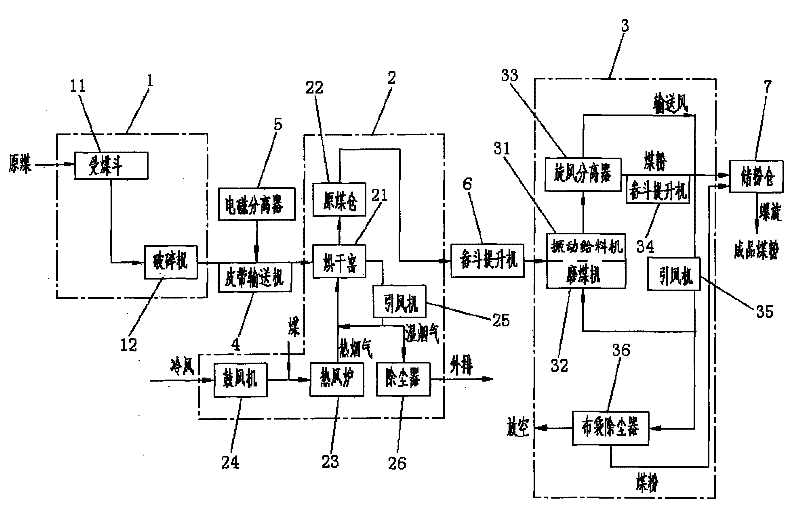

[0013] Such as figure 1 As shown, the pulverized coal preparation system of the present invention includes three parts: a crushing system 1 , a drying system 2 and a grinding system 3 .

[0014] The crushing system 1 includes a coal receiving hopper 11 and a hammer crusher 12 , the discharge port at the bottom of the coal receiving hopper 11 has a gate valve, and the discharge port of the coal receiving hopper 11 is connected to the feed port of the crusher 12 .

[0015] The drying system 2 includes a drum type drying kiln 21, the feed port of the kiln head of the drying kiln 21 communicates with the crusher 12 through a closed belt conveyor 4, and an electromagnetic separator 5 is arranged above the closed belt conveyor 4. The discharge port at the bottom of the drying kiln 21 is connected to the feed port of a raw coal bunker 22 , the air inlet at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com