Highly corrosion-resistant members and processes for production thereof

A technology with high corrosion resistance and manufacturing method, applied in bearing components, rotating parts resistant to centrifugal force, ion implantation plating, etc., can solve problems such as intolerance to long-term use, and achieve excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

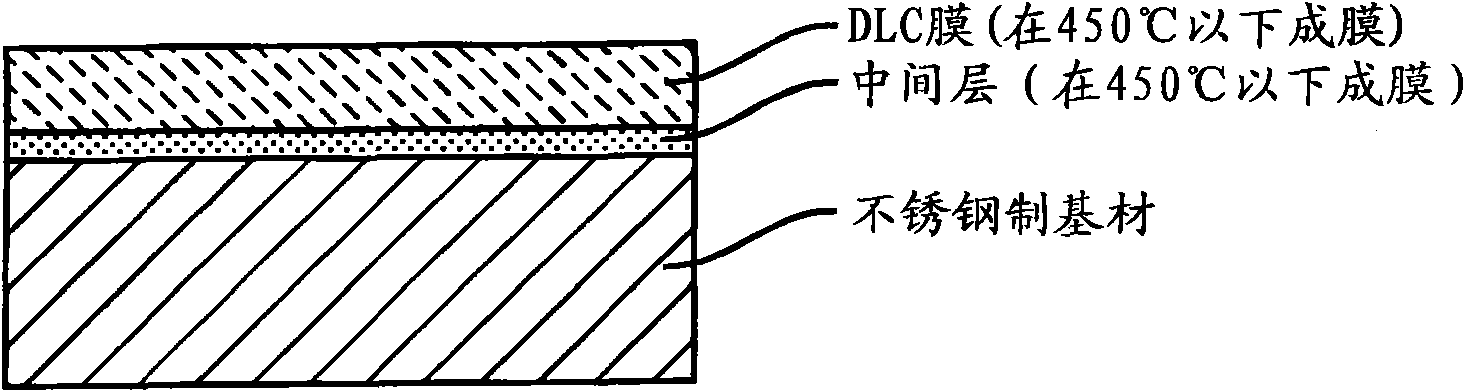

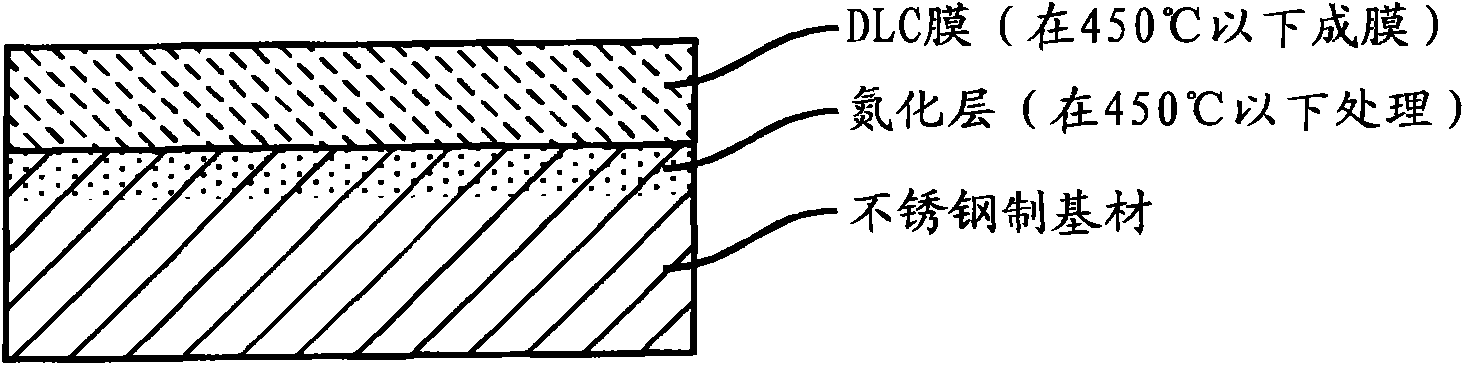

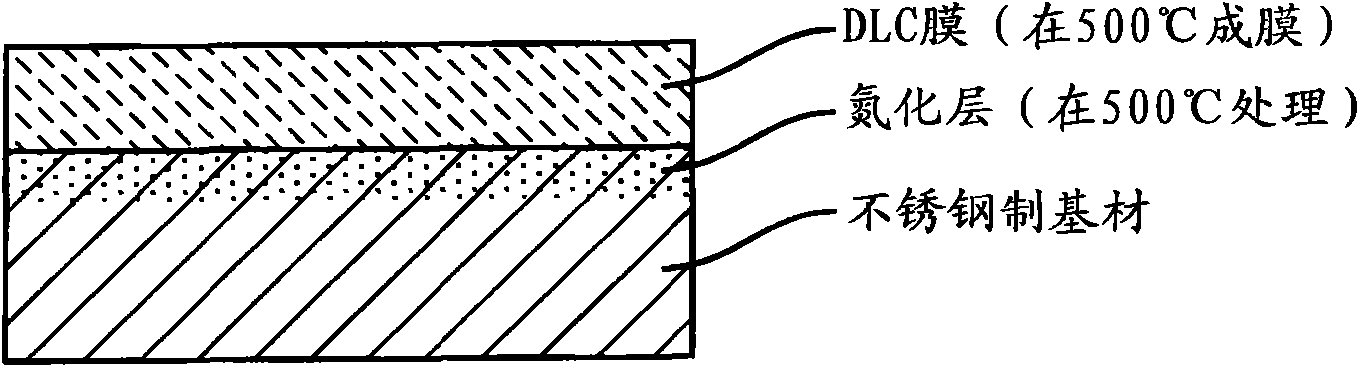

[0063] In the present embodiment, a titanium film (intermediate layer) and a DLC film are formed on the outer peripheral surface of the base material in the following order to produce Figure 4 The pump shaft 10 is shown.

[0064] In addition, a PIG type plasma CVD apparatus (APIG-1060D, hereinafter abbreviated as "PIG") manufactured by Shinko Seiki Co., Ltd. was used for the formation of the titanium film and the DLC film. The PIG device has a plasma source consisting of a hot cathode filament and an anode. The source gas introduced into the device is decomposed and dissociated by the plasma generated in the plasma source, and a film is formed on the surface of the substrate (hot cathode PIG plasma CVD method). In addition, since the sputtering cathode connected to the DC power supply is arranged in this PIG device, the film formation can also be performed by the DC sputtering method. The surface temperature of the substrate is measured by a thermocouple arranged near the sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com