Analysis chip and analysis method

A chip and substance technology, applied in the field of analytical chips, can solve the problems of air bubble obstruction, difference in detection sensitivity, residual air bubbles, etc., and achieve the effect of suppressing residue, high sensitivity, and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

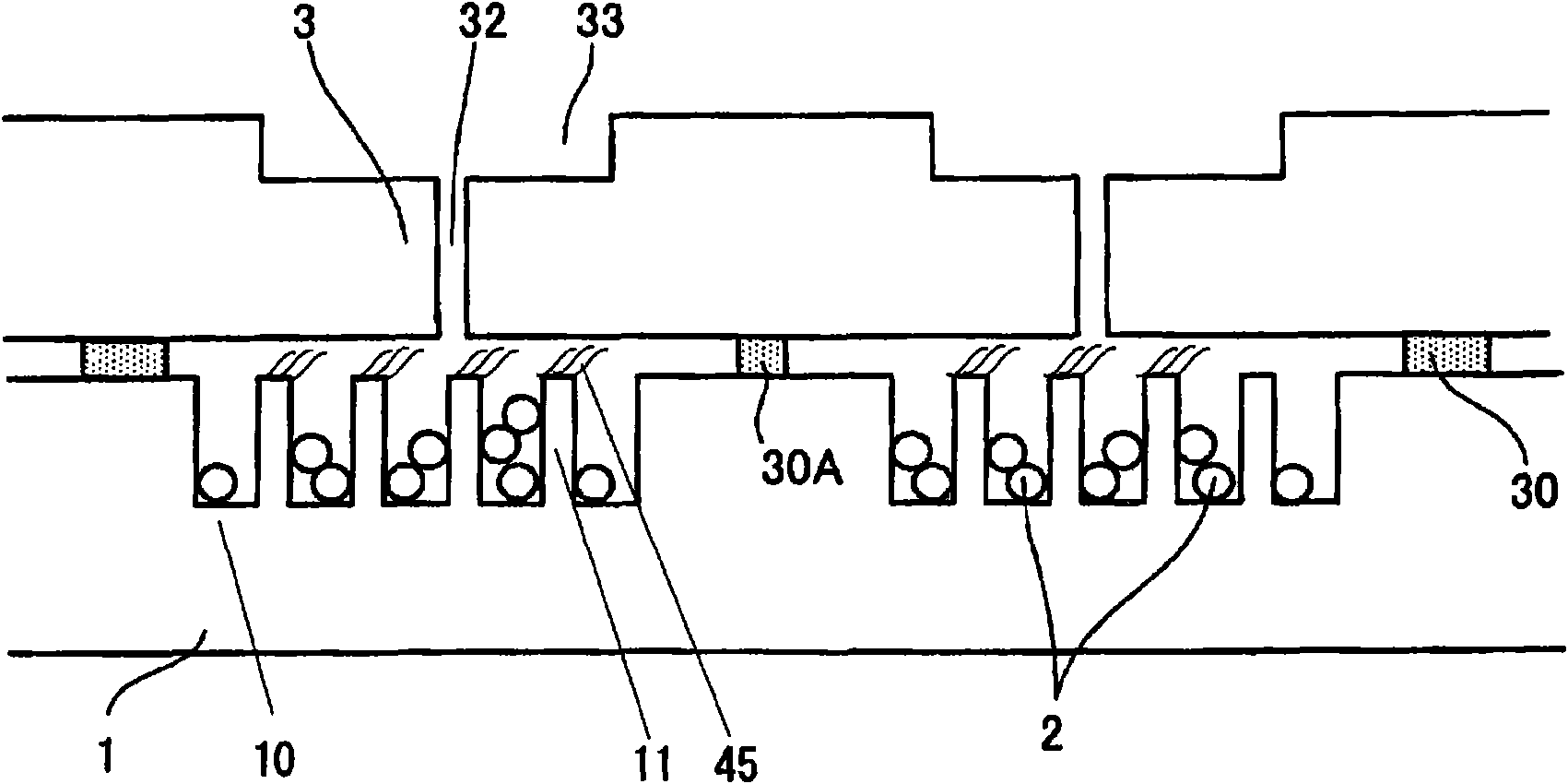

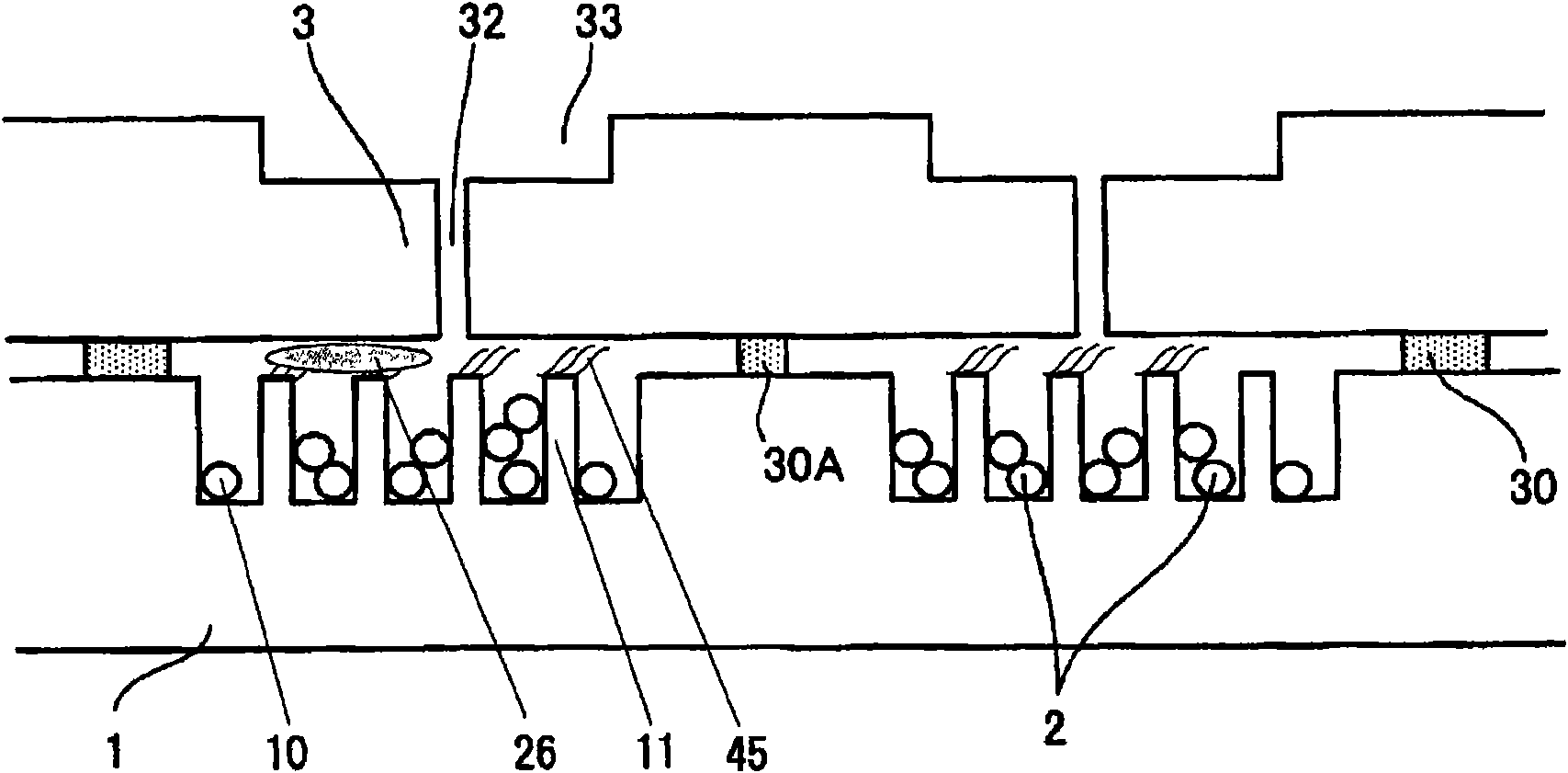

Embodiment 1

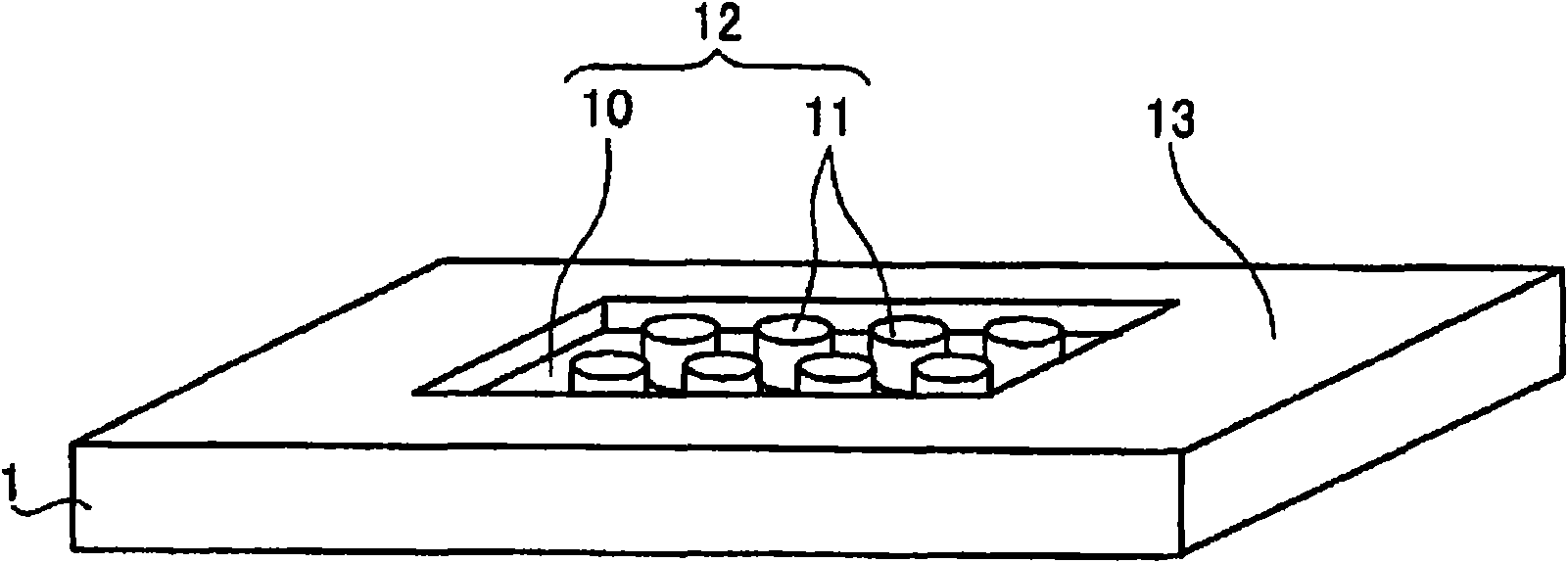

[0142] (1) Fabrication of substrates for analytical chips

[0143] Using LIGA (Lithographie Galvanoformung Abformung) technique which is a well-known method, a mold for injection molding was produced, and a substrate made of polymethyl methacrylate (PMMA) having the following shape was obtained by injection molding. The average molecular weight of the PMMA used was 50,000, carbon black (#3050B manufactured by Mitsubishi Chemical) was contained in PMMA at a ratio of 1% by weight, and the substrate was made black. The spectral reflectance and spectral transmittance of the black substrate were measured. As a result, the spectral reflectance was 5% or less at any wavelength in the visible light region (wavelength of 400nm to 800nm). The rate is 0.5% or less. Neither the spectral reflectance nor the spectral transmittance has a specific spectral pattern (peak, etc.) in the visible light region, and the spectrum is similarly flat. It should be noted that the spectral reflectance i...

Embodiment 2

[0167] Evaluation using the analysis chip 1 was performed in the same manner as in Example 1, except that the test substance solution prepared in Example 1 (6) was degassed as described below.

[0168] 175 μl of the test substance solution was put into a 0.2 ml PCR tube (72.737.002 manufactured by Ashisuto Co., Ltd.), and degassed in a degasser (aspirator NDA-015 manufactured by ULVAC Co., Ltd.) with the cap opened. The ultimate pressure during degassing is 50hPa in the display of the device, and the degassing time is 25 minutes.

[0169] In the same manner as in Example 1 (7), the number of bubbles in the test substance solution observed on the substrate after the hybridization reaction was counted, and the average value of the number of bubbles per 1 time obtained after implementing the result 6 times was: 0.4 (Table 1).

[0170] In addition, in the same manner as in Example 1 (8), when the difference in background signal value (CV value) was calculated, it was 6.7% (Table ...

Embodiment 3

[0181] In Example 1 (4), sodium deoxycholate (one type of anionic surfactant) was used instead of sodium dodecyl sulfate (SDS) as a surfactant, and 120 mg of the surfactant-coated The treated microparticles were prepared to produce "Analysis Chip 3". Using this analysis chip 3, the test substance solution was degassed and evaluated in the same manner as in Example 2.

[0182] The operability of microparticle injection was evaluated in the same manner as in Example 1 (5). As a result, the average time required after 10 implementations was 3 minutes to 5 minutes, so the operability evaluation of microparticle encapsulation into the analysis chip 3 was " B" (Table 2).

[0183] In this analysis chip 3, the number of bubbles generated in the test substance solution was counted after the hybridization reaction in the same manner as in Example 1 (7). As a result, the average number of bubbles after 10 implementations was 0.6 (Table 2).

[0184] In addition, the difference in backgr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com