Fermentation method of soybean paste

A fermentation method and soybean paste technology, which are applied in the field of fermentation engineering, can solve the problems of limited effect, reduced tyrosine concentration, easy reversion and mutation of strains, etc., and achieve the effects of mild operating conditions, simple and convenient operation, and promoting proliferation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

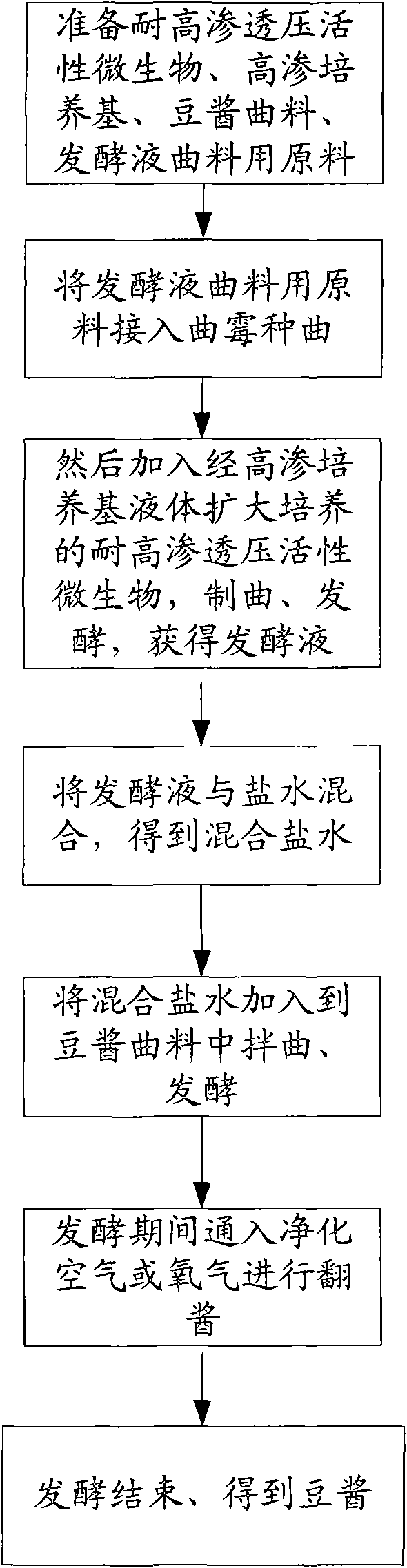

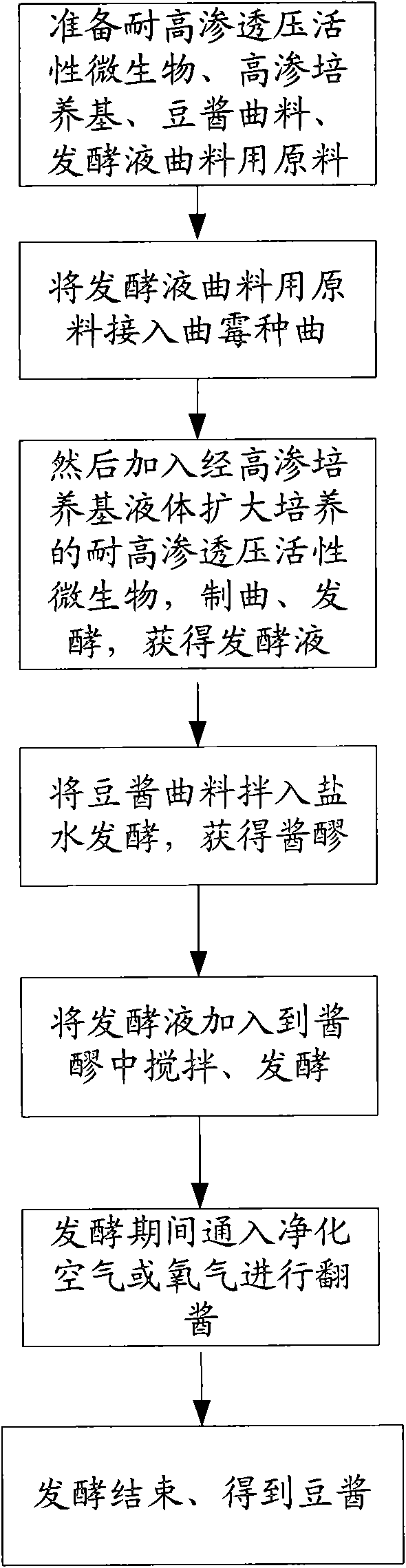

Method used

Image

Examples

Embodiment 1

[0046] 1) Prepare soybean paste koji, hyperosmotic medium with a NaCl content of 10%, hyperosmotic pressure-resistant Luxie yeast screened from soybean paste fermentation liquid, and raw materials for fermentation liquid koji;

[0047] 2) adding Aspergillus seed koji in the raw material for fermented koji;

[0048] 3) After activating hyperosmotic pressure-resistant Luxie yeast on a slant with hyperosmotic medium, carry out liquid expansion culture, and then use 10 2 The addition ratio of cfu / g fermented liquid koji raw materials is added to step 2) in the fermented liquid koji with aspergillus seed koji added to carry out koji making, after the koji making is completed, mix in 1.5 times the salt water of the fermented liquid koji weight, Stir and ferment to obtain a cell concentration of 10 4 cfu / mL fermentation broth;

[0049] 4) mixing the fermentation broth and brine in a weight ratio of 1:2 to obtain mixed brine;

[0050] 5) Mix the mixed brine and soybean paste koji in ...

Embodiment 2

[0054] 1) Prepare soybean paste koji, hyperosmotic medium with a NaCl content of 1%, halophilic Pediococcus halophilus that is resistant to high osmotic pressure screened from soybean paste fermentation liquid, and raw materials for fermentation liquid koji;

[0055] 2) adding Aspergillus seed koji in the raw material for fermented koji;

[0056] 3) After the hypertonic pressure-resistant Pediococcus halophilus is activated on a slant with a hyperosmotic medium, the liquid expansion culture is carried out, and then 10 7 The addition ratio of cfu / g fermented liquid koji raw materials is added to step 2) in the fermented liquid koji with aspergillus seed koji added to carry out koji making, after the koji making is completed, mix in salt water with 2 times the weight of fermented liquid koji, Stir and ferment to obtain a cell concentration of 10 6 cfu / mL fermentation broth;

[0057] 4) mixing the fermentation broth and brine at a weight ratio of 1:10 to obtain mixed brine;

...

Embodiment 3

[0062] 1) Prepare soybean paste koji, hyperosmotic medium with 10% NaCl content, Candida tropicalis, and raw materials for fermented koji;

[0063] 2) adding Aspergillus seed koji in the fermentation broth koji raw materials;

[0064] 3) After the Candida tropicalis resistant to hyperosmotic pressure is activated on a slant with a hyperosmotic medium, the liquid expansion culture is carried out, and then 10 6 The addition ratio of cfu / g fermented liquid koji raw materials is added to step 2) in the fermented liquid koji with aspergillus seed koji added to carry out koji making, after the koji making is completed, mix in 2.5 times the salt water of the fermented liquid koji weight, Stir and ferment to obtain a cell concentration of 10 5 cfu / mL fermentation broth;

[0065] 4) mixing the fermentation broth and brine in a weight ratio of 1:2 to obtain mixed brine;

[0066] 5) Mix the mixed brine and soybean paste koji in a weight ratio of 5:2, mix the soybean paste koji, pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com