Microwave chemical reactor

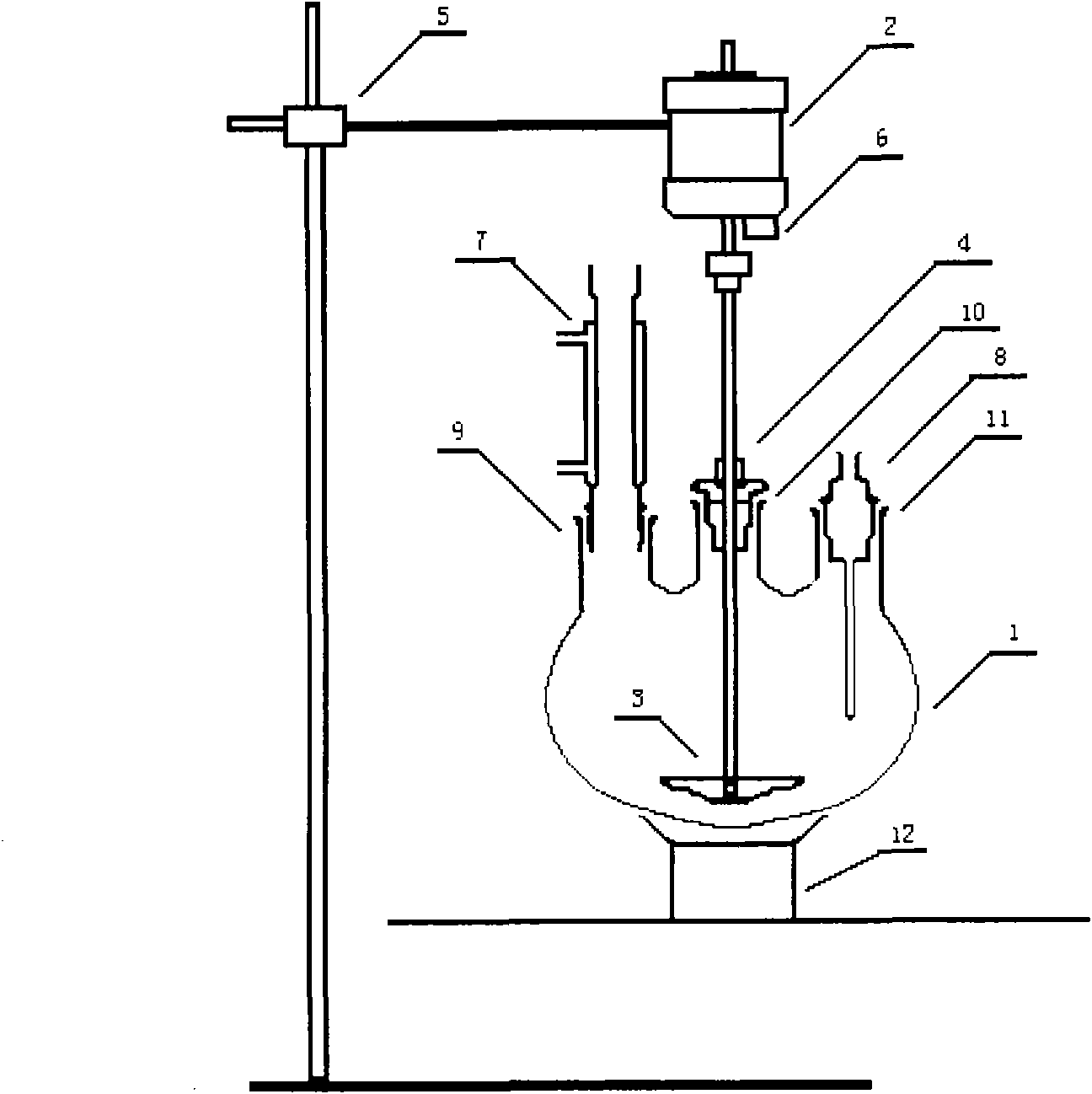

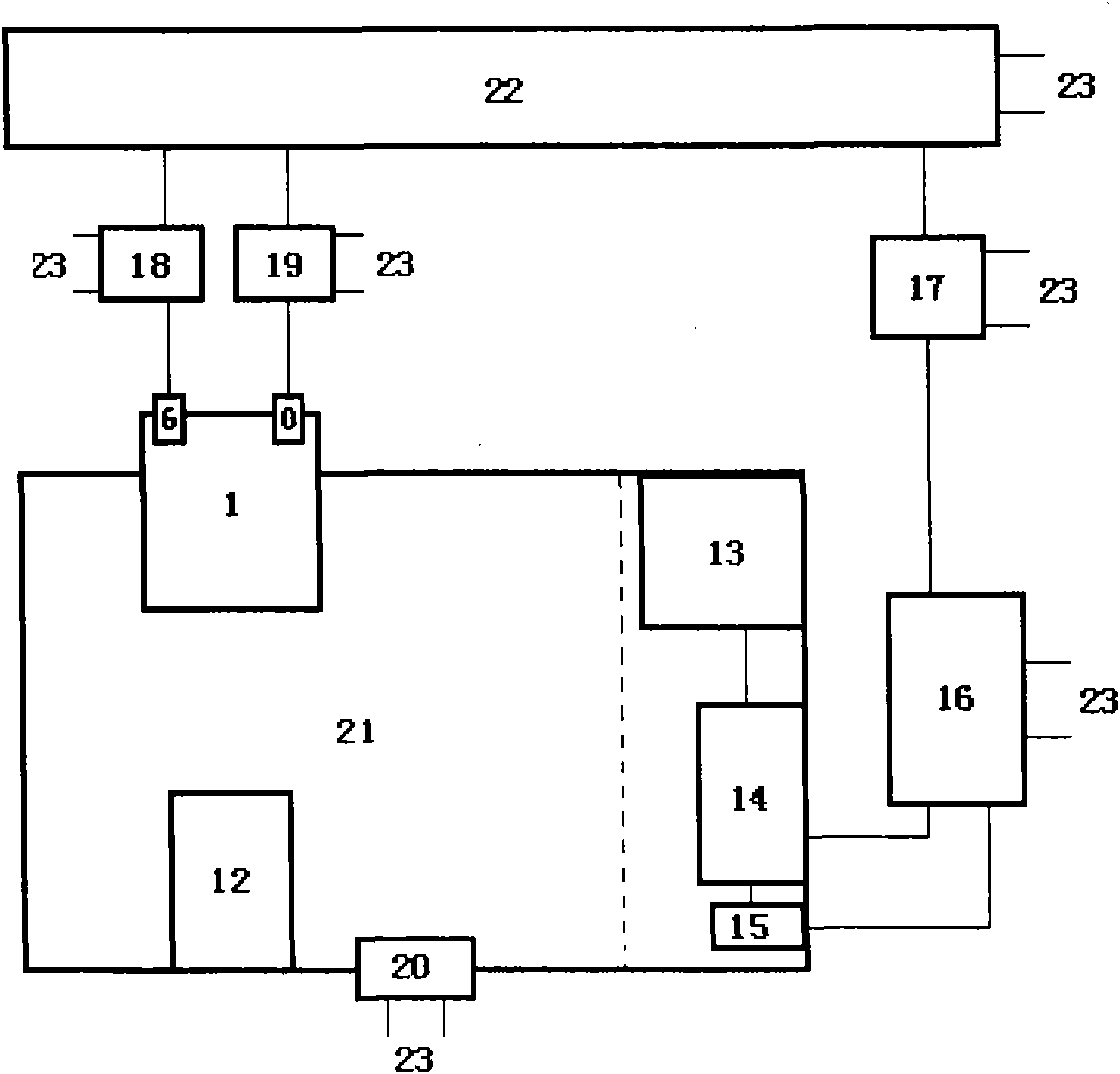

A chemical reactor and microwave technology is applied in the field of atmospheric pressure chemical reactors to achieve the effects of convenient loading and unloading, reducing microwave leakage and facilitating feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Microwave chemical reactors operate in constant power mode. Operate according to the specific embodiment, and the system for measuring is 350ml distilled water. After the instrument was energized, the rotating speed of the mechanical agitator (2) was adjusted to be 350rpm, and the constant power value of the microwave chemical reactor was as follows under the output voltages of different levels of the voltage regulating transformer (16):

[0023] Voltage regulating transformer(16)

[0024] 205±1

Embodiment 2

[0026]Microwave chemical reactors operate in constant power mode. Operated according to the specific embodiment, the measuring system is 350ml of 20% sucrose solution. After the instrument is powered on, adjust the rotating speed of the mechanical stirrer (2) to be 350rpm. After the system boils, use a 5ml pipette to draw the 70mg / 5ml citric acid aqueous solution and insert it from the upper opening of the glass straight condenser tube (7) into the 19 # After grinding port A (9) to a horizontal position, add the above-mentioned citric acid aqueous solution to the system, and take out the pipette. Let the system react under constant power and boiling state. The constant power value and the reaction rate constant of the microwave chemical reactor under different levels of output voltages of the measured voltage regulating transformer (16) are as follows:

[0027] The output voltage / V of voltage regulating transformer (16)

Embodiment 3

[0029] The microwave chemical reactor is regulated to keep the system in a constant temperature mode. The measurement system is 350ml distilled water. Operate according to the specific embodiment, but do not add reactants, only check the temperature fluctuation range when the high voltage is set to 185V and the low voltage is set to 0V in this technology (the difference is the maximum value), and the temperature of the control system is 60°C. Stirring speed: 788±5rpm. After three repeated measurements, each measurement was kept at a constant temperature for more than 1 hour, and the power variation range: 750±5~0J·s -1 , the maximum temperature fluctuation range is ±0.7℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com