Manufacturing method for aluminium alloy automobile hub with high performance and big size

A manufacturing method and technology of automobile wheels, applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve problems such as high cost, low market competitiveness, and complex forming control, and achieve low cost, strong market competitiveness, and improved fatigue Effects on performance and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

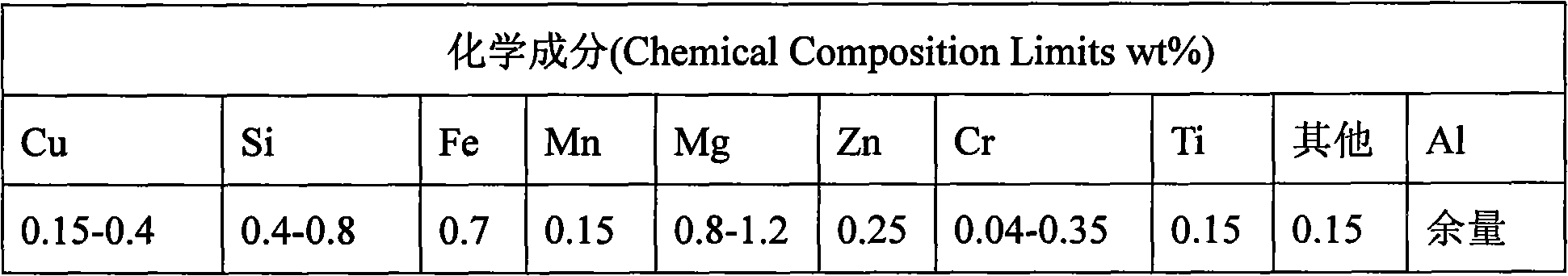

[0014] The present invention will be further described below in conjunction with embodiment. The alloy composition mass percentage (%) of the 6061 aluminum alloy sheet material adopted in the embodiment is:

[0015]

[0016] After melting the 6061 aluminum alloy in a power frequency electric furnace, add SiB with a mass fraction of 0.5% relative to the aluminum alloy 2 As a refiner to refine the grains, and after refining, cool in a static furnace to the liquidus temperature of the alloy within the range of -670°C, keep it warm for 30 minutes, and cast it on a semi-continuous casting machine after primary cooling and secondary cooling. Diameter aluminum alloy cylindrical billet, the casting speed is 125mm / min, the cooling water flow rate is 0.05-0.75m 3 / min. will subsequently The diameter of the aluminum alloy cylindrical billet is heated at a frequency of 618°C for 20 minutes, and its solid phase ratio reaches 65-70%, and then the designed shape is extruded on a 2,50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com