Method for preparing mesoscopic material with controllable appearance

A technology of morphology and gas tube, which is applied in the field of preparation of mesoscopic materials with controllable morphology, can solve the problems of inability to control pore size and structure, limited types of phase separation agents and surfactants, and achieve production costs Low, no environmental pollution, easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, bubble generating device

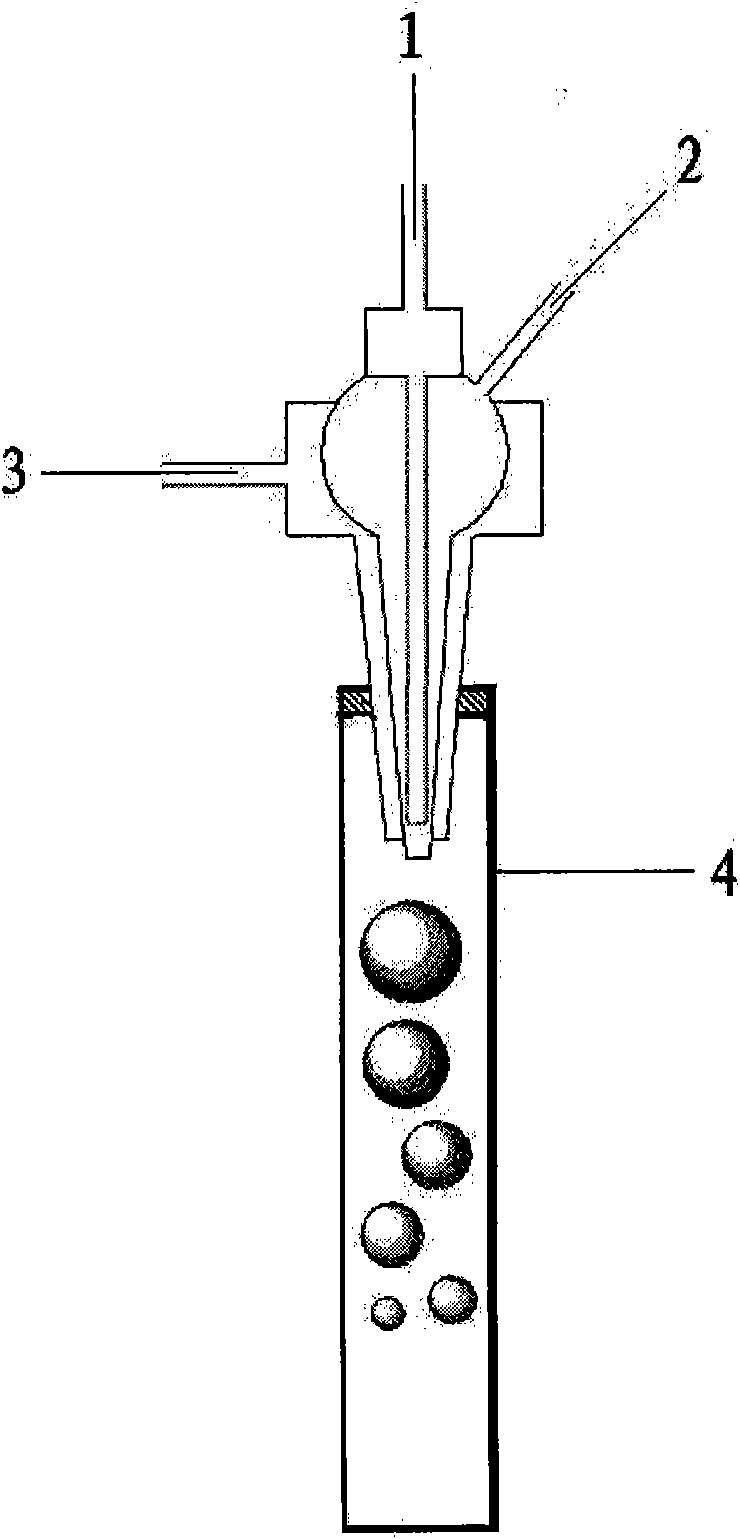

[0037] The special device used in the method for preparing mesoscopic materials with controllable morphology provided by the present invention is a bubble generating device, such as figure 1 As shown, it consists of a three-layer casing including an inner gas pipe 1, an outer gas pipe 3 and a liquid inlet pipe 2, wherein the inner gas pipe 1 is located in the chamber of the liquid inlet pipe 2, and the liquid inlet pipe 2 is located in the outer gas pipe Inside the tube 3 lumens.

[0038] In the above-mentioned bubble generating device, the distance between the inner gas pipe 1 and the liquid inlet pipe 2 is greater than 0 and less than 2 cm. The device may also include a curing channel 4 , the inlet of the curing channel 4 is connected to the gas outlets of the inner gas tube 1 and the outer gas tube 3 .

Embodiment 2

[0039] Embodiment 2, preparation of silica hollow spheres

[0040] The foaming type surfactant SDS (sodium dodecyl sulfate) of 1 weight part, the water of 100 weight parts, the 2M hydrochloric acid of 2 weight parts are mixed homogeneously, then add the tetraethyl orthosilicate of 20 weight parts, reaction 2 After one hour, inject bubbles into the bubbling device, the external air velocity is 400L / h, the internal air velocity is 10L / h, and react at 200°C in a 1m long, 6cm thick glass column, receive it with a flask, and A white powder was collected.

[0041] Hollow spheres of about 120nm can be seen under the transmission electron microscope.

Embodiment 3

[0042] Embodiment 3, preparation of silica hollow spheres

[0043] The foaming type surfactant SDS (sodium dodecyl sulfate) of 1 weight part, the water of 100 weight parts, the 2M hydrochloric acid of 2 weight parts are mixed homogeneously, then add the tetraethyl orthosilicate of 20 weight parts, reaction 2 After one hour, inject bubbles into the bubbling device, the external air velocity is 250L / h, the internal air velocity is 40L / h, and react at 250°C in a 1m long, 6cm thick glass column, receive it with a flask, and A white powder was collected.

[0044] Hollow spheres of about 150nm can be seen under the transmission electron microscope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com