Enzymatic hydrolysis method for cellulosic substance

A technology for cellulosic substances and cellulose, which is applied in the field of continuous enzymatic hydrolysis of cellulosic substances to generate fermentable sugar, can solve the problems of harsh acid hydrolysis conditions, low sugar recovery rate and high sugar cost, and achieves improved recovery rate and reduced hydrolysis. Loss of sugar, effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

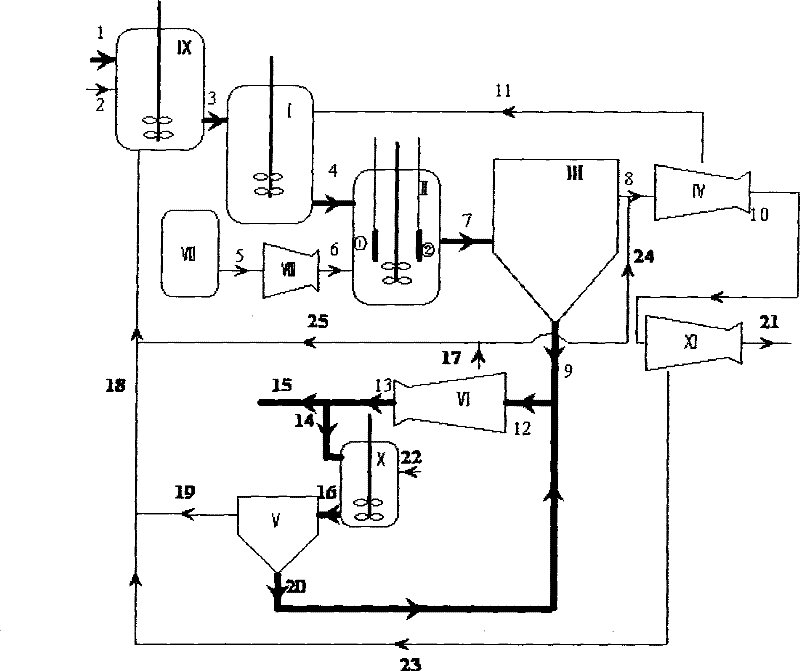

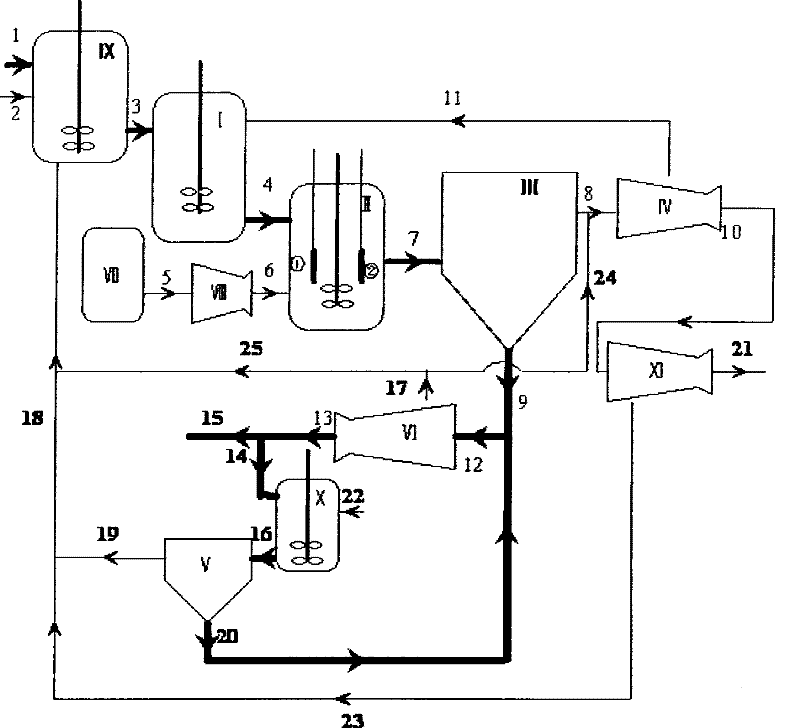

[0021] Such as figure 1 As shown, the equipment used in the process of enzymatic hydrolysis of cellulosic substances of the present invention is as follows: cellulosic substance suspension storage tank I, cellulosic substance hydrolysis tank II, cellulosic substance solid residue natural settling tank III, fiber in the hydrolysis sugar solution Cellulase recovery unit IV, cellulosic solid residue washing natural settling tank V, cellulosic solid residue separation device VI, cellulase storage tank VII, cellulase sterilization device VIII, cellulosic material suspension preparation and disinfection tank IX, cellulosic substance solid residue water washing tank X, hydrolysis sugar liquid concentration device XI, a total of 11 units, each unit can be sealed, and connected with pipelines, the whole device can be steam sterilized and kept sterile.

[0022] The cellulosic substance suspension storage tank I has a stirring device, which can keep the cellulosic substance in a relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com