Compound conducting film and touch screen using same

A composite conductive film and touch screen technology, which is applied in the direction of electrical digital data processing, input/output process of data processing, optics, etc., can solve the problems of reducing the strength of the film, increasing the light absorption of the material, and the conductivity and uniformity of the film layer. , to achieve the effect of improving light transmission performance, satisfying input durability, improving performance and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

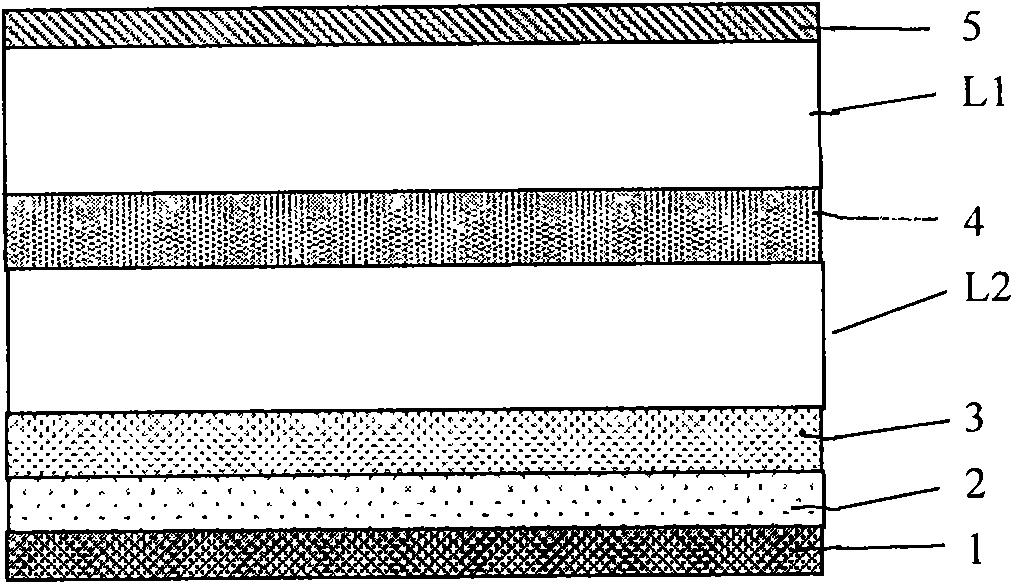

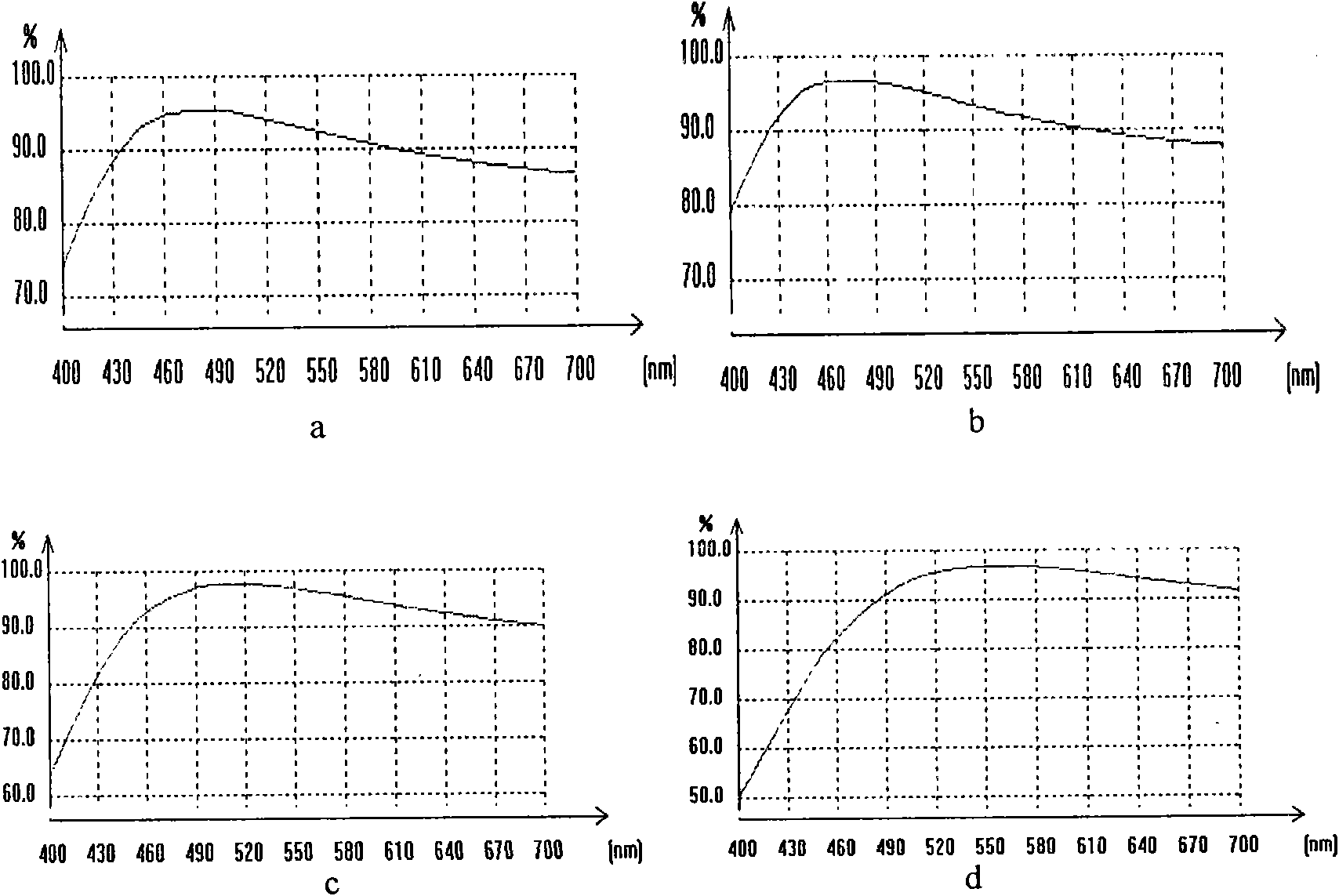

[0029] figure 1 The structure diagram of the composite conductive film of the present embodiment 1 is given, see figure 1 , the first flexible light-transmitting base layer L1 with the upper and lower surfaces is a PET film of 125 μm, and the second flexible light-transmitting base layer L2 with the upper and lower surfaces is a PET film of 75 μm, located on the lower surface of the first flexible light-transmitting base layer L1 and The elastic adhesive layer 4 between the upper surfaces of the second flexible light-transmitting base layer L2 can be made of hot-melt glue or resin, with a thickness of 15 μm. The inorganic dielectric film system and transparent conductive film layer formed by high refractive index inorganic dielectric film and low refractive index inorganic dielectric film are deposited by vacuum magnetron sputtering to form an overall transmittance of more than 80% in the light wavelength range of 380nm to 780nm Optical interference film system. A layer of h...

Embodiment 2

[0047] Figure 4 The structural diagram of the composite conductive film in Example 2 is given. see Figure 4 , this embodiment is basically the same as Embodiment 1, and the difference from Embodiment 1 is that the film system can be formed by interlacing the multi-layer inorganic dielectric film 3 with high refractive index and the inorganic dielectric film 2 with low refractive index, and can also achieve a very high High transmittance. The advantage of the multi-layer film system is that it can reduce the degree of interference of the coating on the color of the transmitted light.

Embodiment 3

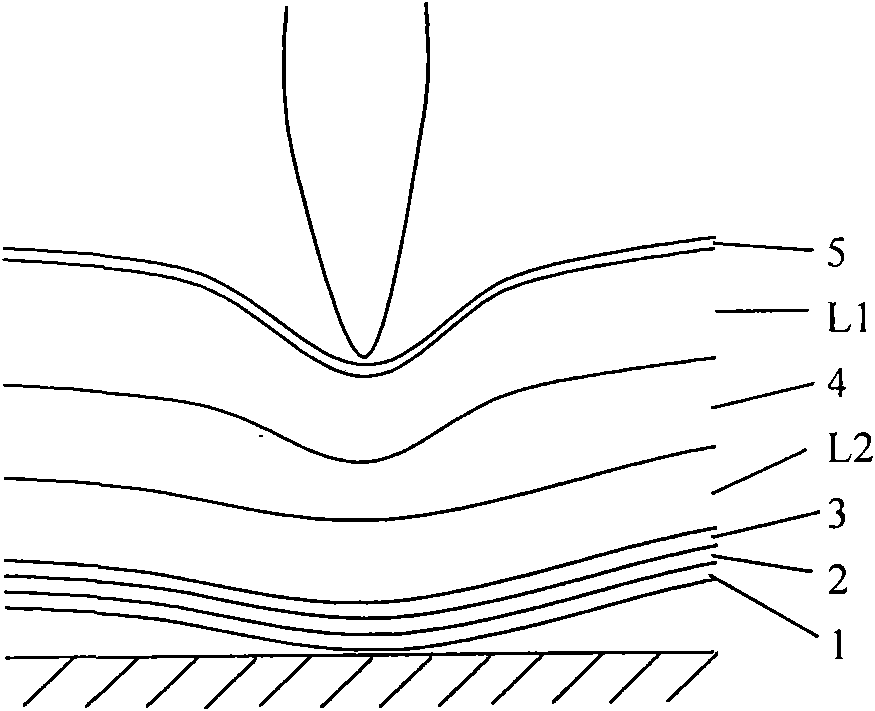

[0049] Figure 5 A schematic diagram of the structure of the touch screen film group in Example 3 is given. see Figure 5 According to the composite conductive film of the present invention, as the upper substrate P1 of the touch screen module, it is opposed to another lower substrate P2 separated by spacers and spacers 6, and the lower substrate P2 can be conductive glass, other conductive films Or the composite conductive film of the present invention. The edge of the transparent conductive film layer is plated / printed with electrodes, which are led out by wires. The composite conductive film according to the present invention can also be used as the lower substrate P2 of the touch screen module.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com