Prepartion method of ternary system quantum dots containing Cd*Zn*Se

A ternary system and quantum dot technology, applied in chemical instruments and methods, non-metal elements, nanostructure manufacturing, etc., can solve the problems of high price, high temperature, high toxicity, etc., and achieve easy large-scale production and difficult production The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

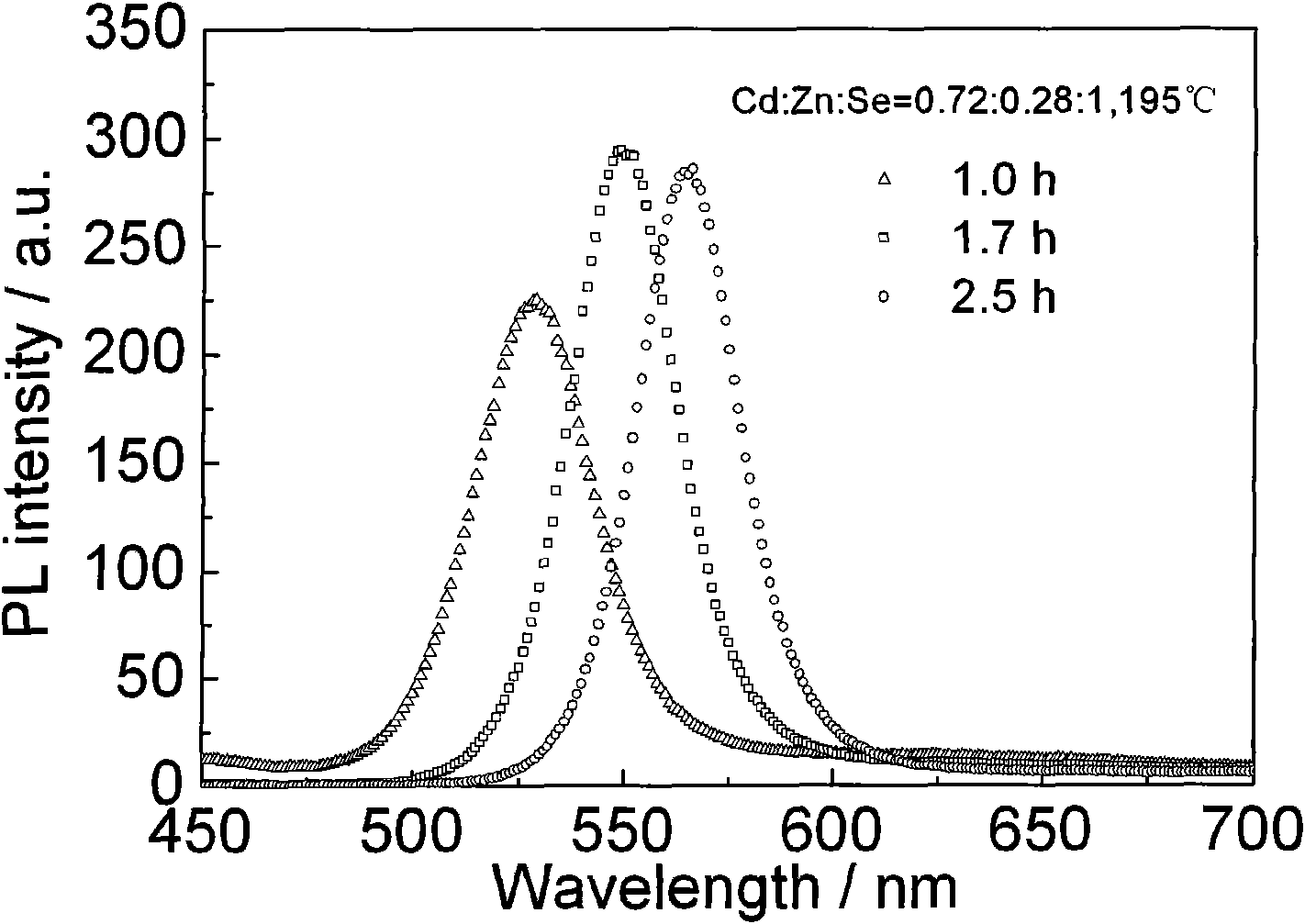

[0014] according to figure 1 , step one; prepare Cd precursor solution: 0.125gCd(MA) 2 (cadmium myristate), 10mL toluene and 0.50mL oleic acid were added to a three-necked flask, heated to 80°C to make Cd(MA) 2 (cadmium myristate) was dissolved in toluene and oleic acid, and then cooled to 60°C for 20 minutes to form a transparent solution; step 2, preparing Zn precursor solution: 0.046gZn(MA) 2 (zinc myristate), 10mL toluene and 0.50mL oleic acid were added to a three-necked flask, heated to 80°C to make Zn(MA) 2 (Zinc myristate) was dissolved in toluene and oleic acid, and then cooled to 60°C for 20 minutes to form a transparent solution; step 3, preparation of Se precursor solution: 0.048g Se powder (0.6mmol) was dissolved in 0.963g trioctyl In base phosphine, vortex at room temperature until completely dissolved, dilute with 40mL toluene, and store in a sealed container; Step 4, Cd x Zn 1-xPreparation of Se ternary system quantum dots: add the above Cd precursor soluti...

Embodiment 2

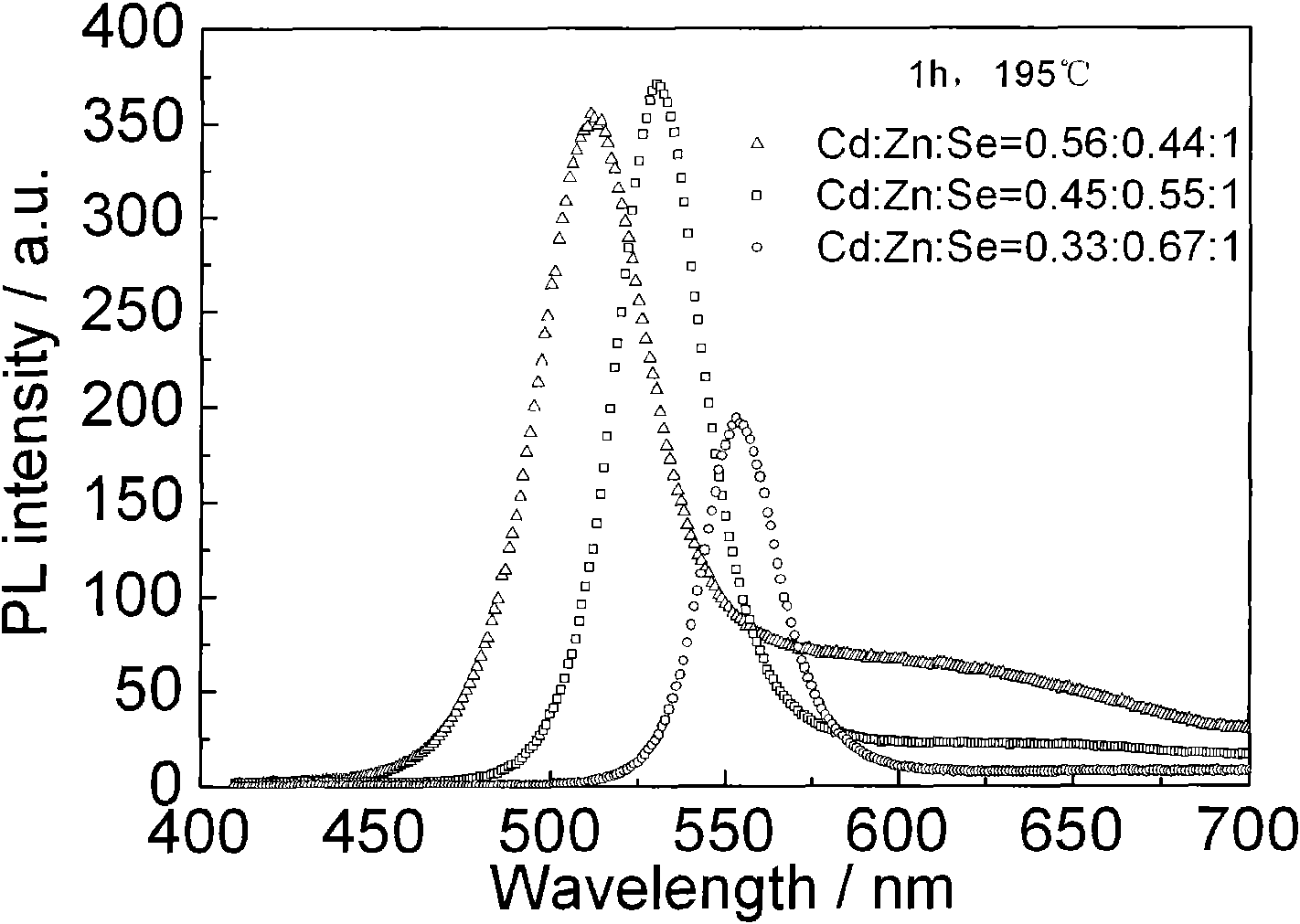

[0016] according to figure 2 , step 1, prepare Cd precursor solution: 0.106gCd(MA) 2 (cadmium myristate), 10mL toluene and 0.50mL oleic acid were added to a three-necked flask, heated to 80°C to make Cd(MA) 2 (cadmium myristate) was dissolved in toluene and oleic acid, and then cooled to 60 ° C for 20 minutes to form a transparent solution; step 2, the preparation of Zn precursor solution: 0.068gZn (MA) 2 (zinc myristate), 10mL toluene and 0.50mL oleic acid were added to a three-necked flask, heated to 80°C to make Zn(MA) 2 (Zinc myristate) was dissolved in toluene and oleic acid, then cooled to 60°C and kept for 20 minutes to form a transparent solution; Step 3, prepare TOP-Se solution: 0.048g Se powder (0.6mmol) was dissolved in 0.963g trioctyl Phosphine, use a vortex shaker until it is completely dissolved, dilute with 40mL, and store in a sealed seal; Step 4, Cd x Zn 1-x Preparation of Se ternary system quantum dots: add the above Cd precursor solution, Zn precursor s...

Embodiment 3

[0018] Step 1, prepare Cd precursor solution: 0.125gCd(MA) 2 (cadmium myristate), 10mL octadecene (ODE) and 0.50mL oleic acid were added to a three-necked flask, heated to 80°C to make Cd(MA) 2 (cadmium myristate) was dissolved in octadecene (ODE) and oleic acid, and then cooled to 60 ° C for 20 minutes to form a transparent solution; step 2, prepare Zn precursor solution: 0.046gZn (MA) 2 (zinc myristate), 10mL octadecene (ODE) and 0.50mL oleic acid were added to a three-necked flask, heated to 80°C to make Zn(MA) 2 (Zinc myristate) was dissolved in octadecene (ODE) and oleic acid, then cooled to 60°C and kept for 20 minutes to form a transparent solution; Step 3, prepare TOP-Se solution: 0.048g Se powder (0.6mmol) was dissolved in In 0.963g trioctylphosphine, use a vortex shaker until completely dissolved, dilute with 40mL octadecene (ODE), and keep in a sealed container; Step 4, Cd x Zn 1-x Preparation of Se ternary system quantum dots: add the above Cd precursor solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com