Hydrolytic oxidization processing system for high-concentration medical waste water

A hydrolysis oxidation and treatment system technology, applied in biological water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Operation and maintenance difficulties and other problems, to save investment costs and operational inconvenience, eliminate biological hazards, and realize the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

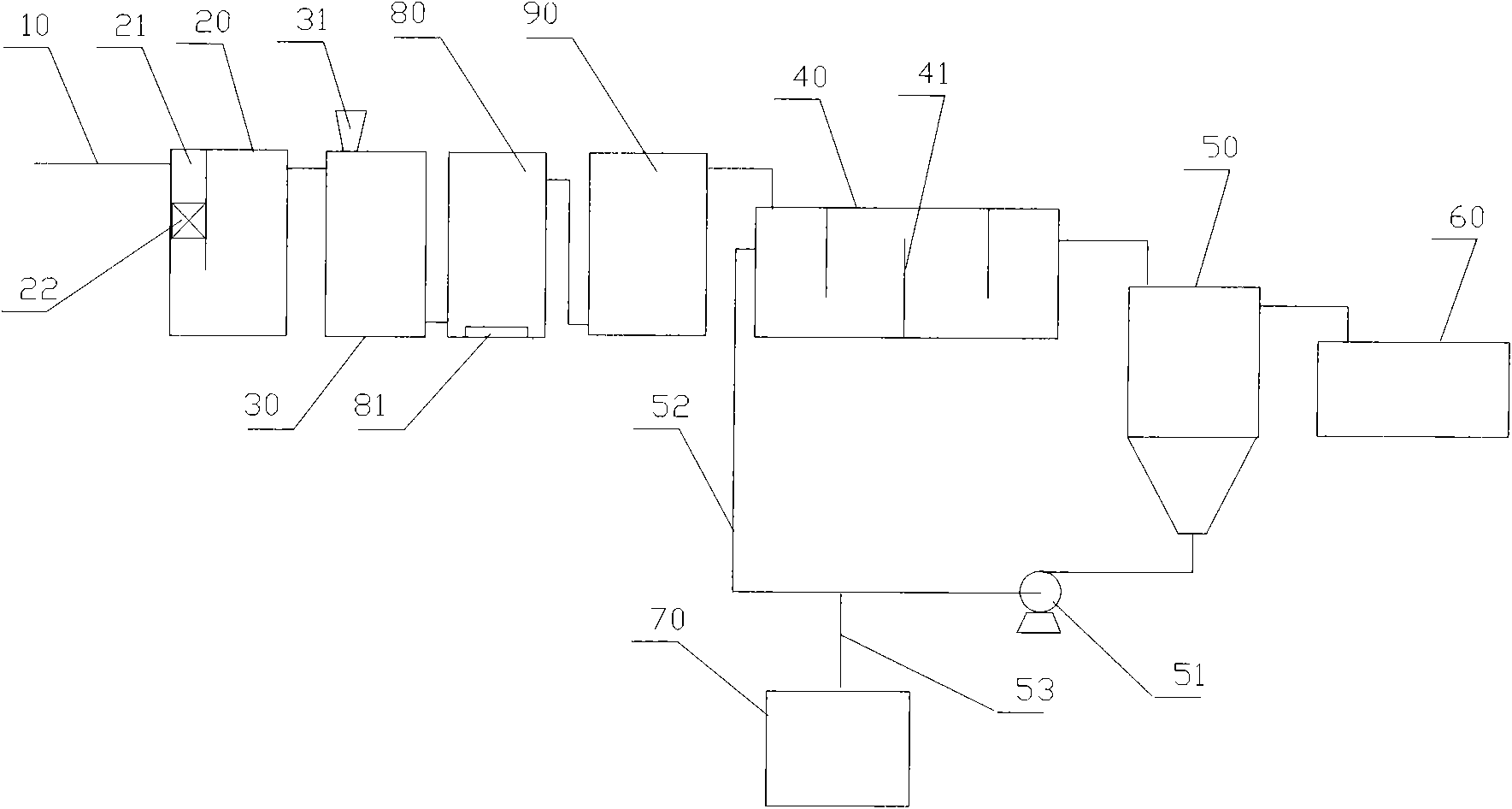

[0009] see figure 1 , the present invention provides a hydrolysis and oxidation treatment system for high-concentration medical wastewater, comprising a sealed sump 20, a sealed sterilization tank 30, a disinfectant removal tank 80, a hydrolysis tank 90, an activated sludge tank 40 and a secondary sedimentation tank Pool (secondary settling tank) 50, the water inlet pipe 21 of the closed sump is provided with a pipeline wet pulverizer 22, the closed sump and the closed sterilization tank are connected by pipeline sealing, and the de-sterilized The agent pool is provided with an aerator at the bottom of the pool or a disinfectant neutralizing drug dispenser at the top of the pool. The water inlet of the hydrolysis tank is located at the lower part, and the water outlet is located at the upper part. The water inlet of the activated sludge biological oxidation tank Both the water outlet and the water outlet are located in the upper part, and some vertical baffles are arranged in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap