Method for preparing hexafluoroacetone

A technology of hexafluoroacetone and hexafluoroisobutenol is applied in the field of preparation of industrial-scale hexafluoroacetone, and can solve the problems of increasing the manufacturing cost of the reaction vessel, increasing capital and labor costs, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

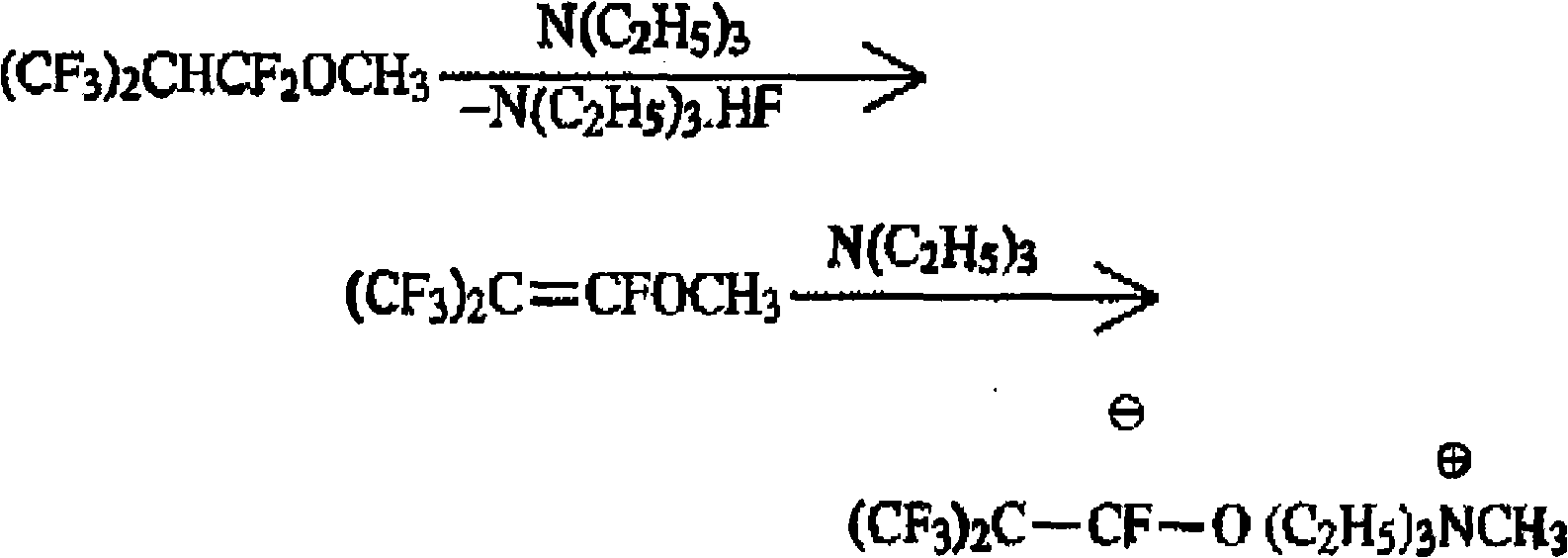

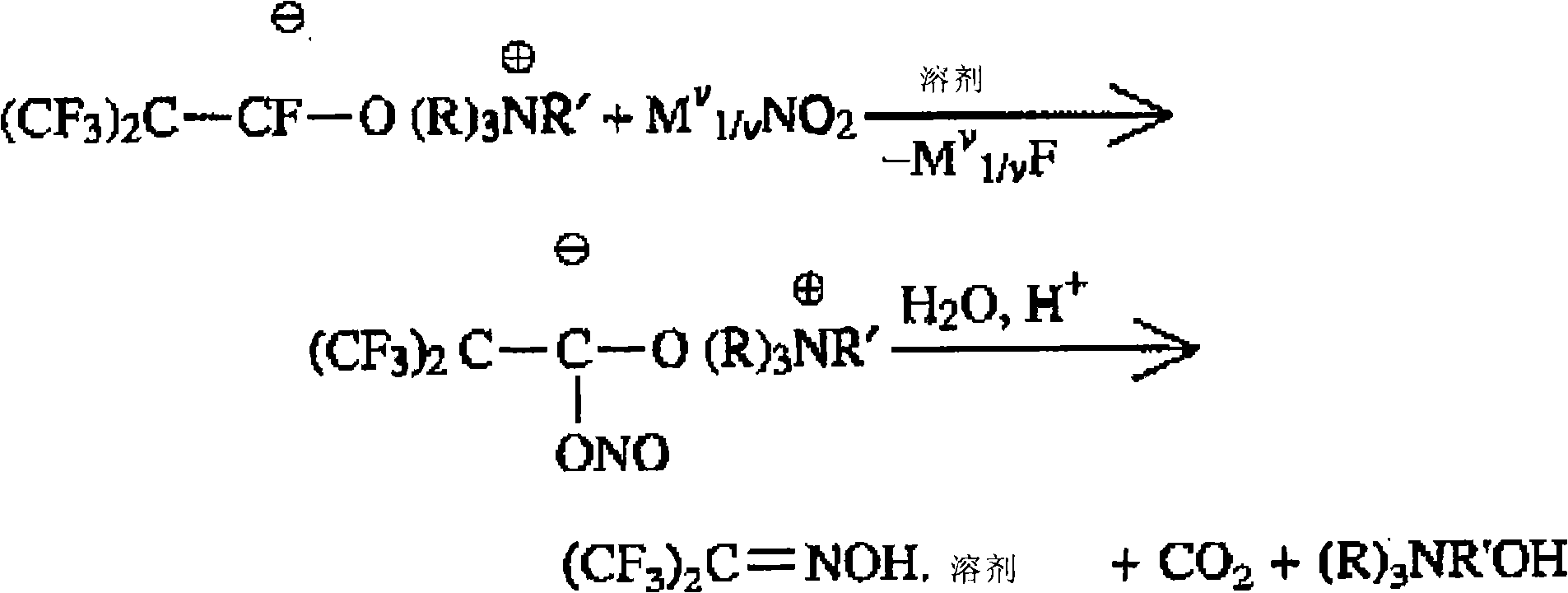

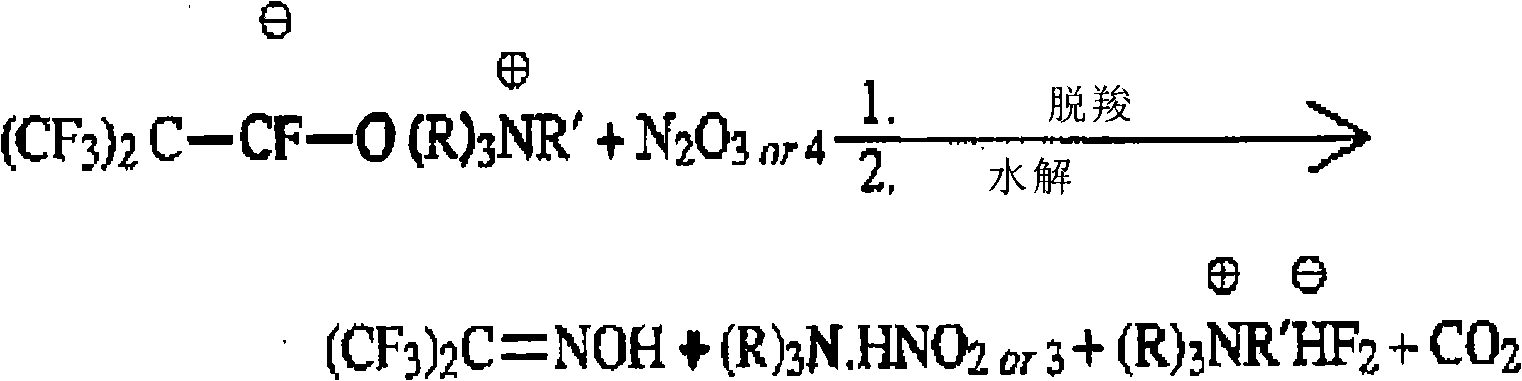

Method used

Image

Examples

Embodiment 1

[0080] Add 110.4 grams (0.5M) of 1-methoxy-1-perfluoroisobutene (purity 96%) and 100 milliliters of acetonitrile (water content 150ppm) in 500 milliliters of three-necked flasks, add 51 grams under the condition of stirring and cooling (0.5M) triethylamine, and the mixture was kept at room temperature for 1.5 hours to obtain a reaction mixture of tetramethylammonium salt of hexafluoroisobutenol in a stable state for use.

[0081] Add 48.5 grams (0.7M) of sodium nitrite and 100 milliliters of acetonitrile (water content 150ppm) in a 500 milliliter three-necked flask at one time, connect the bubbler bottle (add liquid paraffin in the bubbler bottle) at the tail gas discharge port, Slowly add the above-mentioned tetramethylammonium salt reaction mixture of hexafluoroisobutenol in a steady state to the three-necked flask containing the acetonitrile dispersion of sodium nitrite at a controlled flow rate under vigorous stirring and cooling, Control the release rate of carbon dioxide...

Embodiment 2

[0090] Add 263 grams (1.1M) of 1-methoxy-2H-octafluoroisobutane (purity 95%) and 200 milliliters of acetonitrile (water content 150ppm) in a 1000 milliliter three-necked flask, add under stirring and cooling 222 g (2.2 M) of triethylamine, and the mixture was kept at room temperature for 1.5 hours to obtain a reaction mixture of tetramethylammonium salt of hexafluoroisobutenol in a stable state for use.

[0091] Add 111 grams (0.7M) of sodium nitrite and 300 milliliters of acetonitrile (water content 150ppm) at one time in 1000 milliliters of three-necked flasks, connect the bubble bottle (in the bubble bottle, add liquid paraffin) at the tail gas discharge port, Slowly add the above-mentioned tetramethylammonium salt reaction mixture of hexafluoroisobutenol in a steady state to the three-necked flask containing the acetonitrile dispersion of sodium nitrite at a controlled flow rate under vigorous stirring and cooling, Control the release rate of carbon dioxide and maintain th...

Embodiment 3

[0100] In a 1000 milliliter three-necked flask, such as 110.4 grams (0.5M) of 1-methoxy-1-perfluoroisobutene (purity 96%) and 80 milliliters of acetone (water content 200ppm), add 51 gram (0.5M) of triethylamine, and the mixture was kept at room temperature for 1.5 hours to prepare a reaction mixture of tetramethylammonium salt of hexafluoroisobutenol in a stable state for use.

[0101] Add 51 grams (0.7M) sodium nitrite and 50 milliliters of acetone (water content 200ppm) of 99.5% sodium nitrite and 50 milliliters of acetone (water content 200ppm) in 500 milliliters of three-necked flasks at one time, connect bubble bottle (in bubble bottle, add liquid paraffin) at tail gas discharge port, Slowly add the above-mentioned tetramethylammonium salt reaction mixture of hexafluoroisobutenol in a steady state to the three-necked flask containing the acetone dispersion of sodium nitrite at a controlled flow rate under vigorous stirring and cooling, Control the release rate of carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com