Nanometer hole metal-organic frame material in single-level or multilevel pore canal structure and preparation method thereof

A technology of pore structure and nano-holes, applied in the fields of organic chemistry, non-metallic elements, copper-organic compounds, etc., can solve the problems of difficulty in preparing nano-hole metal-organic framework materials, disappearance, and limited material development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

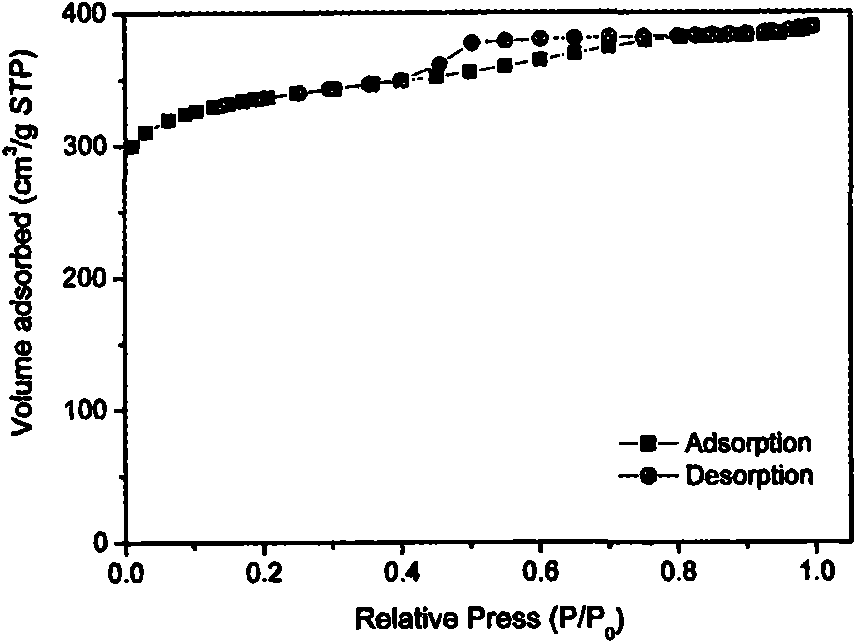

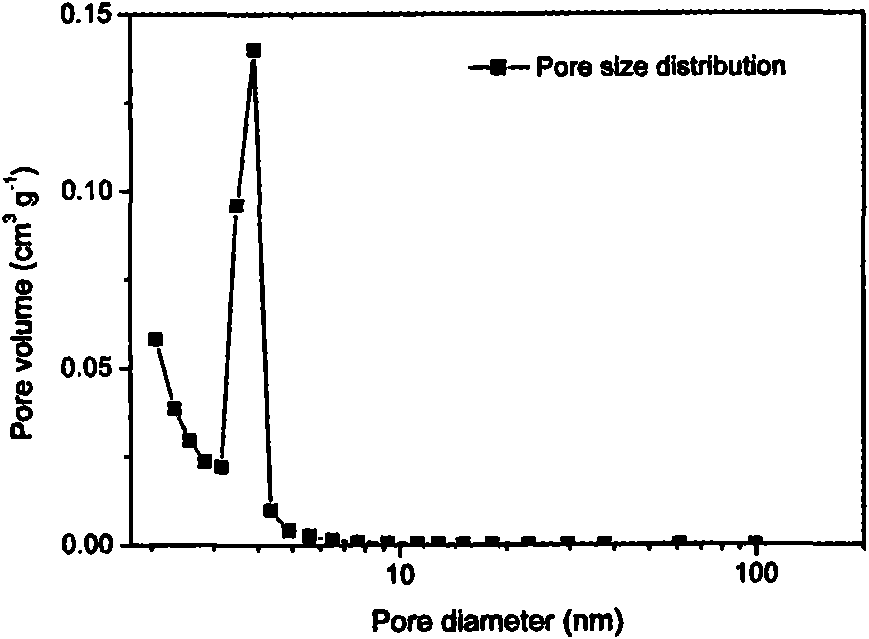

[0038] Weigh 1.093 g (0.0045 mol) of copper nitrate trihydrate and dissolve it in 15 mL of water as reaction component A. Weigh 0.525 g (0.0025 mol) of 1,3,5-benzenetricarboxylic acid and dissolve it in 15 mL of ethanol as reaction component B. Weigh 0.495 g (0.00136 mol) of cetyltrimethylammonium bromide as reaction component C. Add reaction component A to reaction component B, or add reaction component B to reaction component A, put it into a 60mL reactor, then add reaction component C to the reactor containing the mixture of A and B , stir and mix evenly, place the reaction kettle in an oven or dry box and heat to 120 degrees Celsius, and the reaction time is 12 hours. The obtained reaction mixture was suction filtered, washed with 50 mL of water, and washed once with 10 mL of ethanol, then the product was put into a round bottom flask, and 50 mL of ethanol was added to heat to reflux for 3 hours. After the reflux is completed, suction filter, then put the solid product i...

Embodiment 2

[0041] Weigh 1.093 g (0.0045 mol) of copper nitrate trihydrate and dissolve it in 15 mL of water as reaction component A. Weigh 1.05 g (0.0025 mol) of 1,3,5-benzenetricarboxylic acid and dissolve it in 15 mL of ethanol as reaction component B. Weigh 0.495 g (0.00136 mol) of cetyltrimethylammonium bromide as reaction component C. Weigh 0.163 g (0.00136 mol) of 1,3,5-trimethylbenzene as reaction component D. Add reaction component A to reaction component B, or add reaction component B to reaction component A, put it into a 60mL reaction kettle, then add reaction components C and D into the reaction kettle, and stir evenly. The reaction kettle is placed in an oven or a drying box and heated to 120 degrees Celsius, and the reaction time is 12 hours. The obtained reaction mixture was suction filtered, washed with 50 mL of water, and washed once with 10 mL of ethanol, then the product was put into a round bottom flask, and 50 mL of ethanol was added to heat to reflux for 3 hours. ...

Embodiment 3

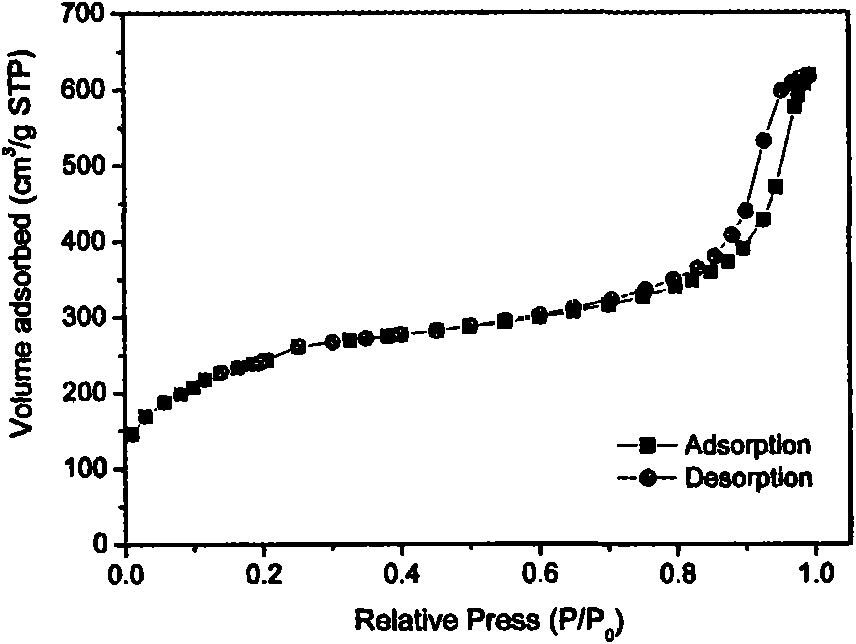

[0044] Weigh 1.093 g (0.0045 mol) of copper nitrate trihydrate and dissolve it in 15 mL of water as reaction component A. Weigh 0.525 g (0.00125 mol) of 1,3,5-benzenetricarboxylic acid and dissolve it in 15 mL of ethanol as reaction component B. Weigh 1.62 g (0.01 mol) of triethanolamine as reaction component C. Add reaction component A to reaction component B, or add reaction component B to reaction component A, put it into a 60mL reaction kettle, then add reaction component C to the reaction kettle, and stir evenly. The reaction kettle is placed in an oven or a drying box and heated to 120 degrees Celsius, and the reaction time is 12 hours. The obtained reaction mixture was suction filtered, washed with 50 mL of water, and washed once with 10 mL of ethanol, then the product was put into a round bottom flask, and 50 mL of ethanol was added to heat to reflux for 3 hours. After the reflux is completed and the suction filtration is completed, the product is put into a round-bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com