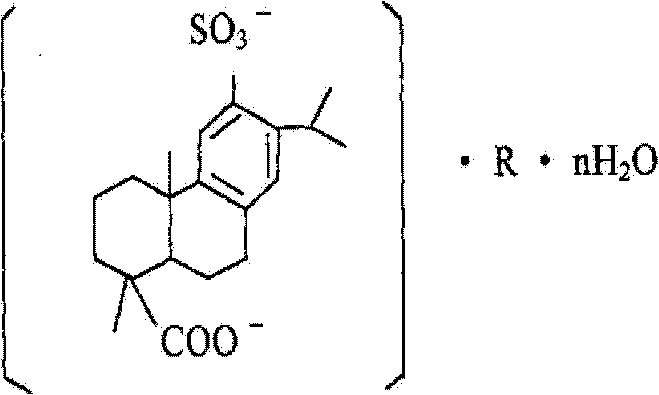

preparation method of disodium sulfodehydroabietate (DSDA) and composition

A technology of disodium abietic acid and dehydroabietic acid, which is applied in the direction of drug combination, medical preparations containing active ingredients, digestive system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

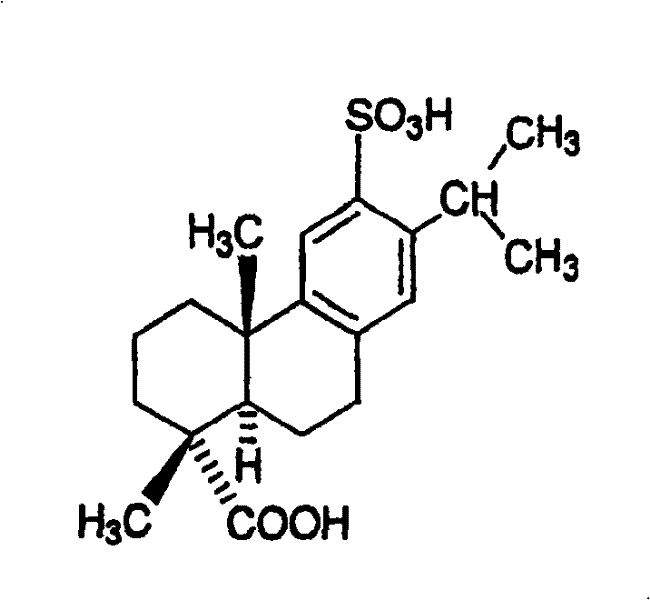

[0203] Preparation of disodium sulfonated dehydroabietic acid:

[0204] (1) Preparation of abietic acid

[0205] Take 5 kg (about 15.5 mol) of golden yellow 310 resin, that is, rosin calcium grease, crush it, place it in a three-necked flask equipped with a stirrer and a reflux condenser, add 3 L of industrial ethyl acetate (about 30.6 mol) and 600 ml of hydrochloric acid, Adjust the pH value to 3-4, heat and reflux under stirring, react for 1 hour, stop stirring and let stand for a while, so that the insoluble matter settles completely, pour out the supernatant while it is hot, and place the supernatant for crystallization (about 2 days). Filtrate, wash the filter cake with an appropriate amount of ethyl acetate, combine the lotion and filtrate, concentrate and recover about 1L of ethyl acetate, continue to place it for crystallization, crystallize and filter out, then wash with industrial ethyl acetate, dry the crystallization, and obtain crude abietic acid A total of 2225g...

Embodiment 2

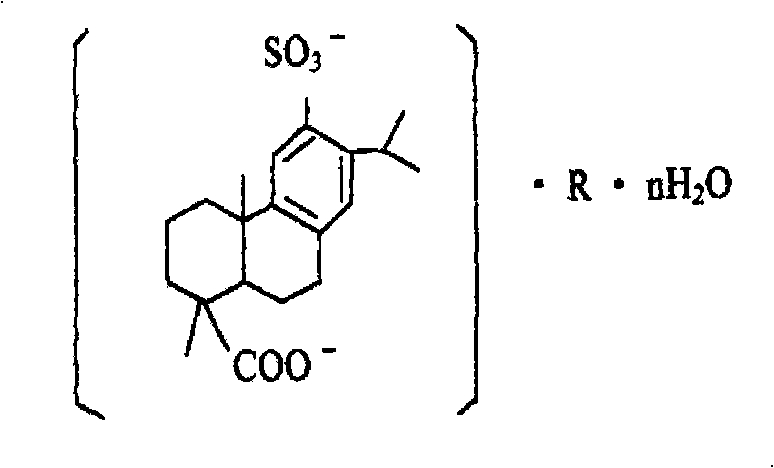

[0215] Preparation of disodium sulfonated dehydroabietic acid granules, capsules and solutions:

[0216] (1) The weight proportion of combination and the binder selected in each prescription are listed in Table 8

[0217] The weight ratio of combination and the selected adhesive unit in each prescription of table 8: gram

[0218] Raw materials

Prescription 1

Prescription 2

Prescription 3

Prescription 4

Prescription 5

Prescription 6

Prescription 7

Disodium sulfonated dehydroabietic acid (calculated as anhydrous matter)

500

500

500

500

500

500

500

300

400

500

400

300

400

500

70

40

70

70

40

70

90

10% pvp

water

30% ethanol

70% ethanol

95% ethanol

10% pvp ethanol solution

5% pvp ethanol solution

[0219] (2) Pulverize disodium sulfonated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com