Fly ash heat preservation plate material production device

A technology for production equipment and thermal insulation boards, applied in the direction of supply equipment, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of unfavorable resources and environmental protection, limitation of thermal insulation effect, insufficient strength, etc., to achieve resource utilization and reduce boards Density, the effect of improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

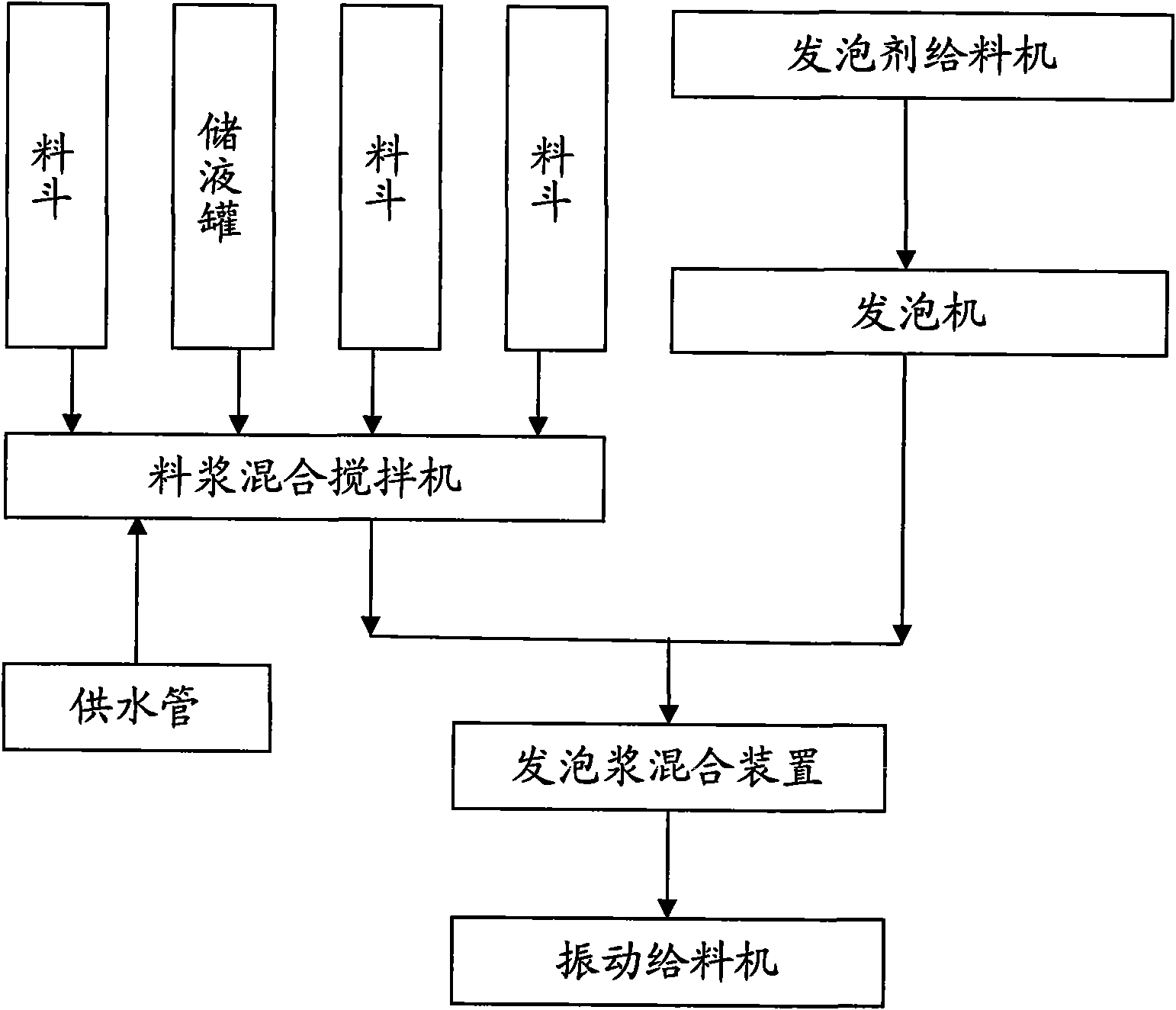

[0007] see figure 1 , the present invention provides a kind of fly ash insulation plate production device, is made up of slurry mixing mixer, foaming agent, foaming slurry mixer and extruding molding machine, the outlet of described slurry mixing mixer and foaming agent are respectively The feed port of the foamed slurry mixer is connected by a screw feeder, the outlet of the foamed slurry mixer is connected to the feed end of the extruder, and the slurry mixing paddle is provided with a light burning Magnesium powder feed hopper, fly ash feed hopper, glass fiber feed hopper and magnesium chloride solution feed pipe are respectively connected to light-burned magnesium powder hopper, fly ash hopper, glass fiber hopper and Magnesium chloride solution storage tank.

[0008] The proportioning of the main raw materials of the slurry is: 200 parts of fly ash (parts by mass, the same below), 100-150 parts of lightly burned magnesium powder, 1-2 parts of oxalic acid, 5-15 parts of gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com