Zinc-aluminum-titanium-carbon intermediate alloy refiner, preparation method thereof and use thereof

A master alloy and refining agent technology, applied in the field of metal materials, can solve problems such as pollution, prolonging the holding time, and environmental pollution, and achieve the effects of simple operation process, prolonging the holding time, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

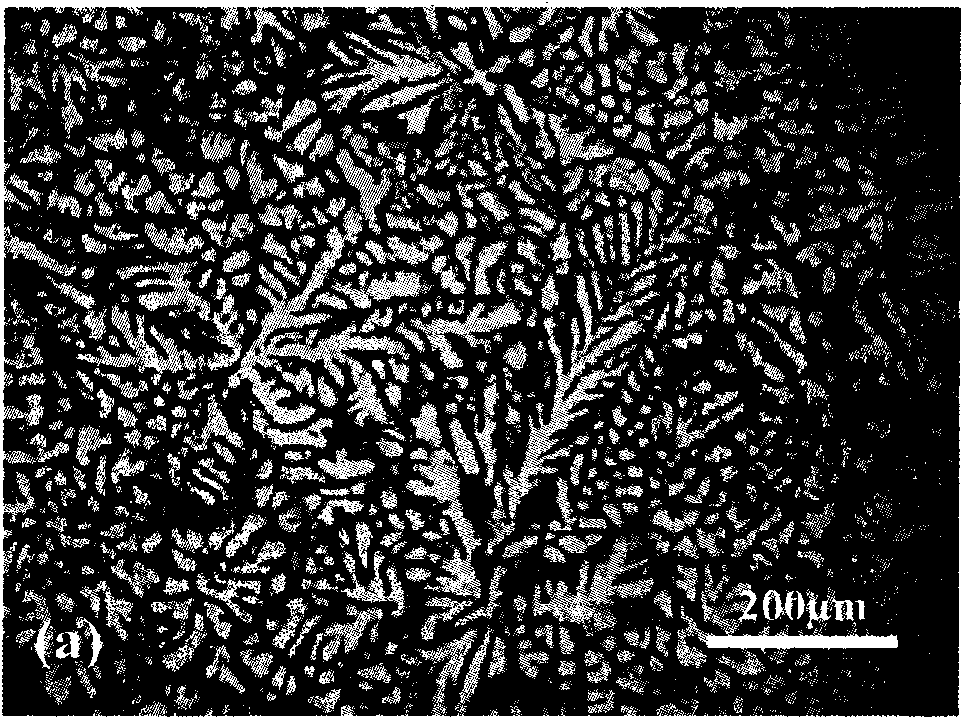

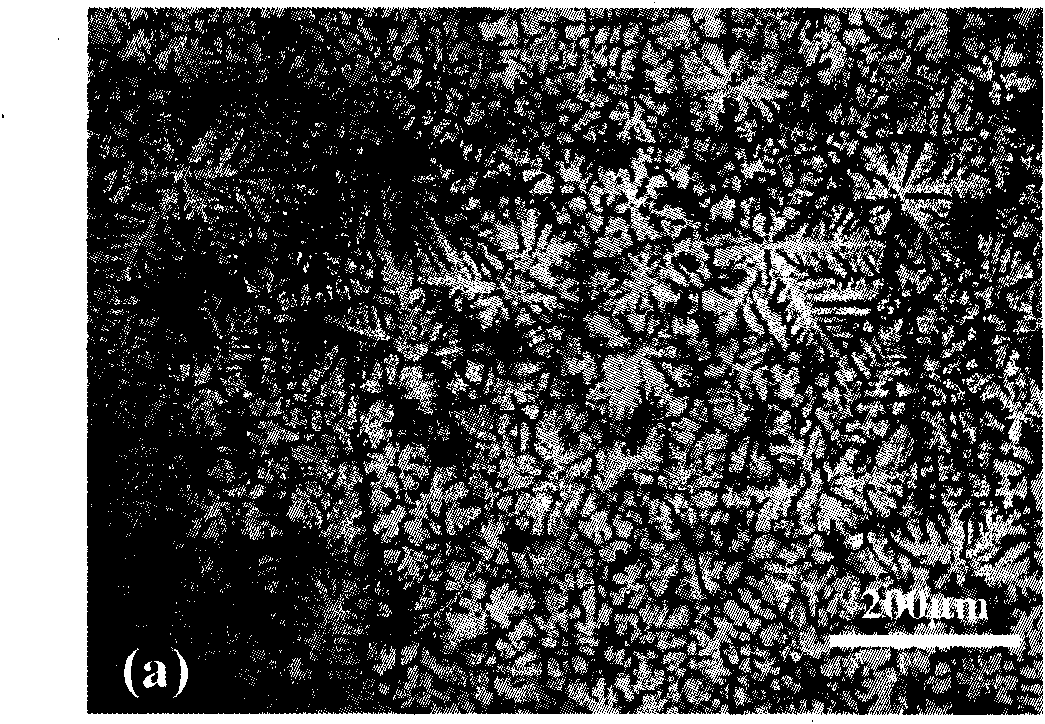

Embodiment 1

[0024] According to the following mass proportions: 47.2% pure zinc, 47.2% pure aluminum, 5% titanium sponge, 0.6% graphite powder; mix titanium sponge and graphite powder, divide into several parts, each part has a mass of 0.1-2 kg and wrap it in aluminum foil , standby; use a medium-frequency induction furnace to melt industrial pure aluminum to between 1000-1300 ° C, then add the inclusions of the mixture of titanium sponge and graphite powder to the molten aluminum in batches, react for another 5 minutes, and stop heating. Add pure zinc after the melt temperature drops to about 920°C, and then continue heating, and the temperature is controlled between 750-900°C. During the heating process, the electromagnetic stirring effect of the medium-frequency induction furnace is used to mix the components in the melt evenly, and then the melt is poured into the casting mold to obtain the zinc-aluminum-titanium-carbon intermediate alloy refiner. The composition of the obtained refin...

Embodiment 2

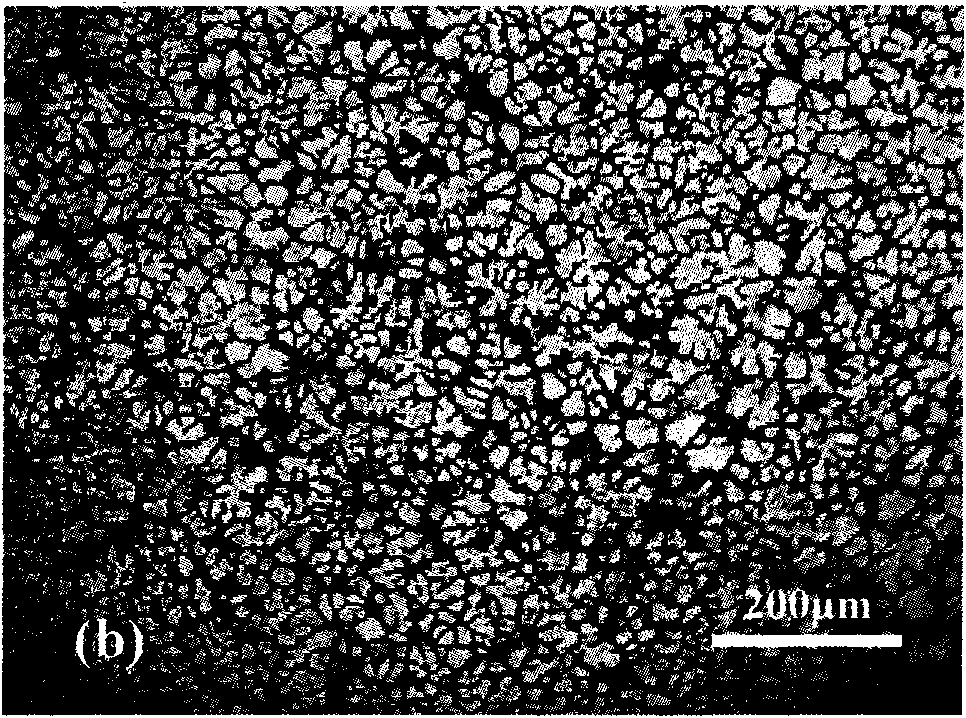

[0027] According to the following mass proportions: 71.6% pure zinc, 24% pure aluminum, 4% titanium sponge, 0.4% graphite powder; mix titanium sponge and graphite powder, divide into several parts, each part has a mass of 0.1-2 kg and wrap it in aluminum foil , Fen Fen; Melt pure aluminum to 1200°C in an intermediate frequency induction furnace, add Fen Nong sponge titanium and graphite powder mixture inclusions to the molten aluminum in batches, continue to react for 10 minutes, and stop heating. After the temperature of the above-mentioned melt drops to about 950°C, pure zinc is added, and the heating is continued, and the temperature is controlled between 700-850°C. During the heating process, the electromagnetic stirring effect of the medium-frequency induction furnace is used to mix the components in the melt evenly, and then the melt is poured into the mold, and after solidification, the zinc-aluminum-titanium-carbon intermediate alloy refiner is obtained. Its chemical co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com