Color filter, manufacture method thereof, and liquid crystal display unit

A manufacturing method and technology of color filters, which are applied in the direction of optical filters, photoplate making process of pattern surface, instruments, etc., can solve problems such as unevenness of color filters, reduction of production rate and cost, time-consuming and labor-intensive, etc., and achieve simple cost , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0289] At the time of preparation of the photosensitive coloring composition, it is preferable to further add the following epoxy resin as a binder polymer other than the said alkali-soluble resin. Examples of epoxy resins include compounds having two or more epoxy rings in the molecule, such as bisphenol A epoxy resins, cresol novolac epoxy resins, biphenyl epoxy resins, and alicyclic epoxy compounds. .

[0290]For example, examples of bisphenol A epoxy resins include EPOTOHTO YD-115, YD-118T, YD-127, YD-128, YD-134, YD-8125, YD-7011R, ZX-1059, YDF-8170, YDF-170, etc. (all of the above are manufactured by Tohto Chemical Co., Ltd.), DENACOLEX-1101, EX-1102, EX-1103, etc. (all of the above are manufactured by Nagase Chemical Co., Ltd.), PLACCEL GL-61, GL-62, G101, G102 (the above are all manufactured by Daicel Chemical Industry Co., Ltd.), etc. Moreover, as an epoxy resin which can be used, the similar bisphenol F type epoxy resin and bisphenol S type epoxy resin are mentione...

Embodiment 1

[0441]

[0442] -Preparation of Carbon Black Dispersion (K-1)-

[0443] A carbon black dispersion (K-1) was prepared according to the following recipe.

[0444] ・Carbon black (COLOR BLACK FW2 manufactured by Degussa Co., Ltd.) 26.7 parts

[0445] Dispersant (Kusumoto Kasei DISPARLON DA7500 acid value 26 amine value 40)

[0446] ...3.3 servings

[0447] ・Benzyl methacrylate / methacrylic acid (=72 / 28 [molar ratio]) copolymer (molecular weight 30000, 50% by mass solution of propylene glycol monomethyl ether acetate)

[0448] ...10 copies

[0449] ·Propylene glycol monomethyl ether acetate ...60 parts

[0450] The above-mentioned components were stirred for 1 hour using a homogenizer under the condition of 3000 rpm. The obtained mixed solution was microdispersed for 8 hours in a bead disperser (trade name: DESPERMAT, manufactured by Getzmann) using 0.3 mm zirconium...

Embodiment 2~ Embodiment 5

[0606] [Example 2 to Example 5, Comparative Example 2]

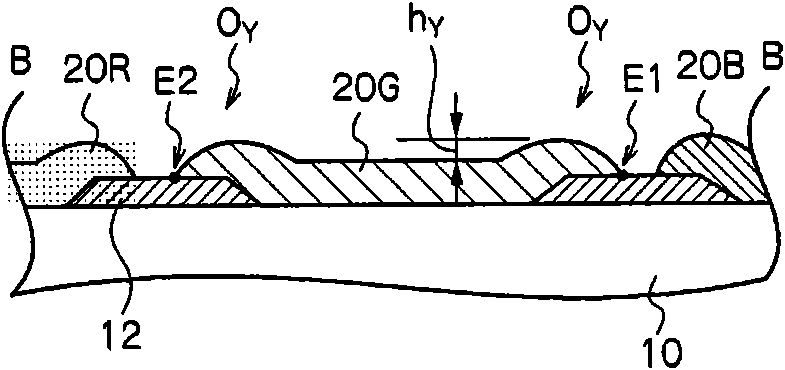

[0607] In addition to the film thickness of the resin black matrix, the cone length L B , film thickness of green pattern, cone length L C and the overlap O Y the length L O Except changing as shown in Table 2, a color filter and a liquid crystal display device were produced in the same manner as in Example 1, and the same evaluation as in Example 1 was performed. The evaluation results are shown in Table 2.

[0608] In detail, the film thickness of the resin black matrix is changed by adjusting the ejection amount of the slit coater, and the cone length L is changed by adjusting the developing time of the developing device. B .

[0609] In addition, the film thickness of the green pattern can be changed by adjusting the discharge amount of the slit coater, and the cone length L can be changed by adjusting the developing time of the developing device. C , by adjusting the exposure time of the exposure device to c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com