Method for extracting titanium dioxide from titaniferous materials

A technology of titanium dioxide and titanium raw materials, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high water consumption, environmental pollution, waste and by-products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

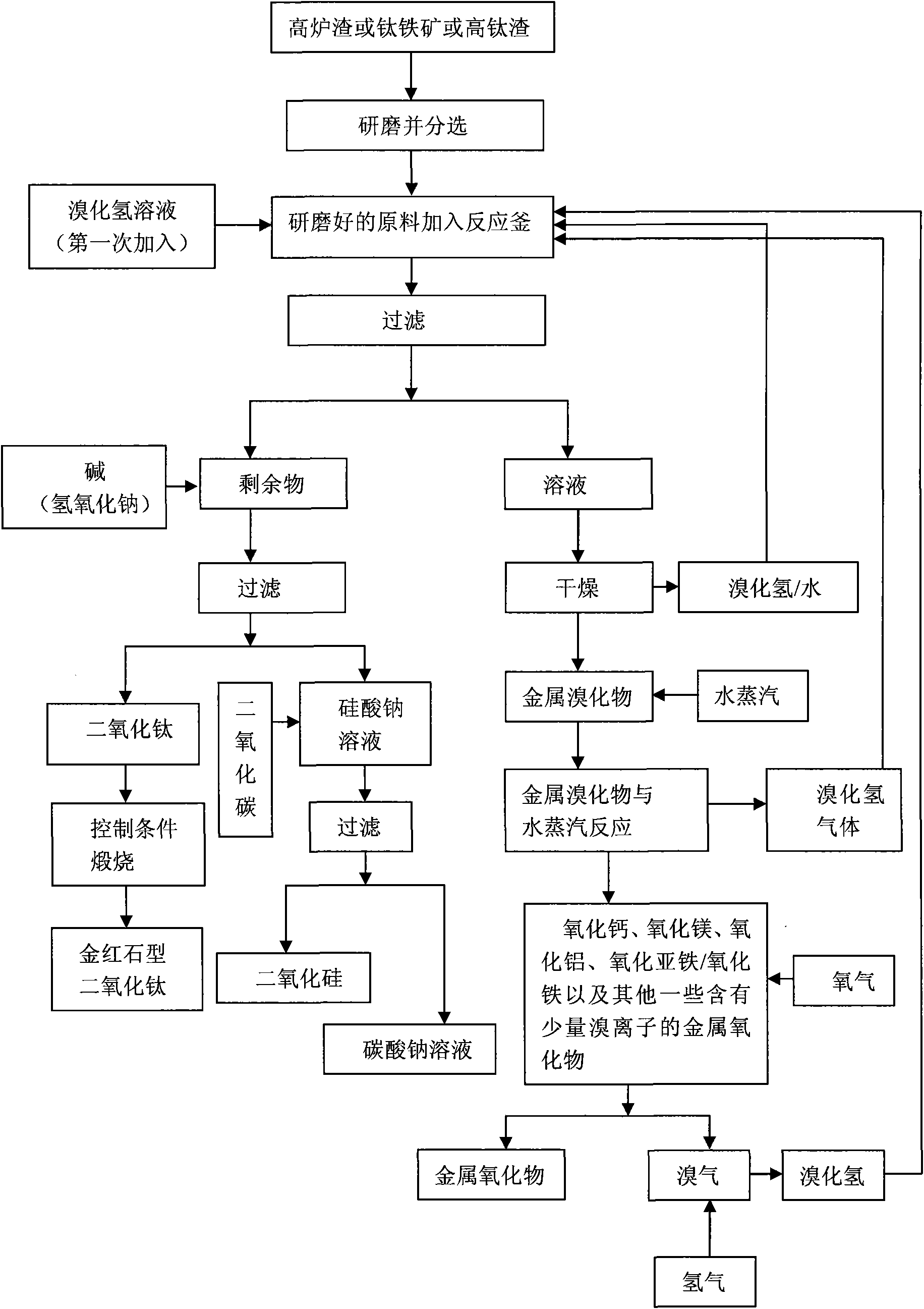

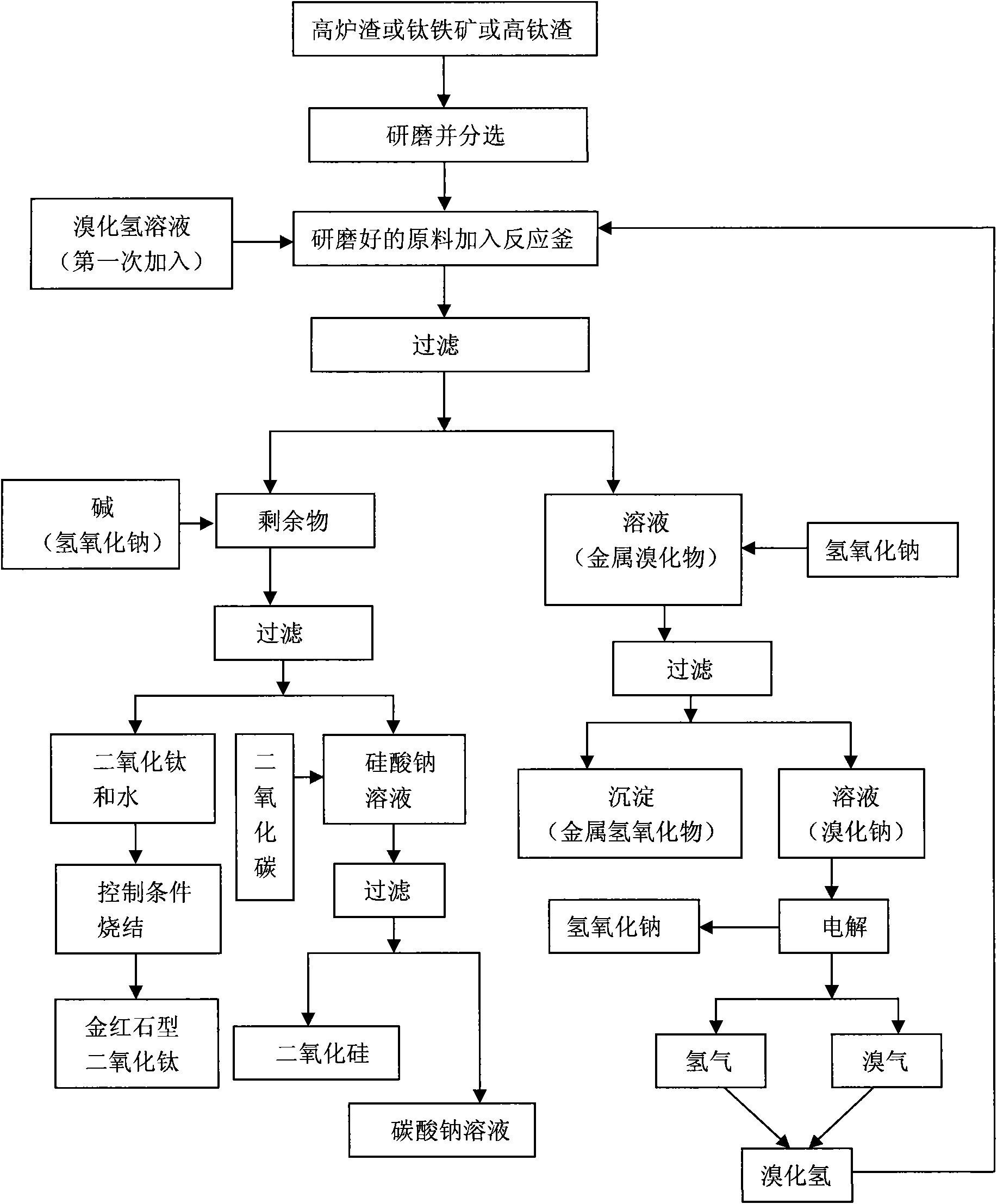

Method used

Image

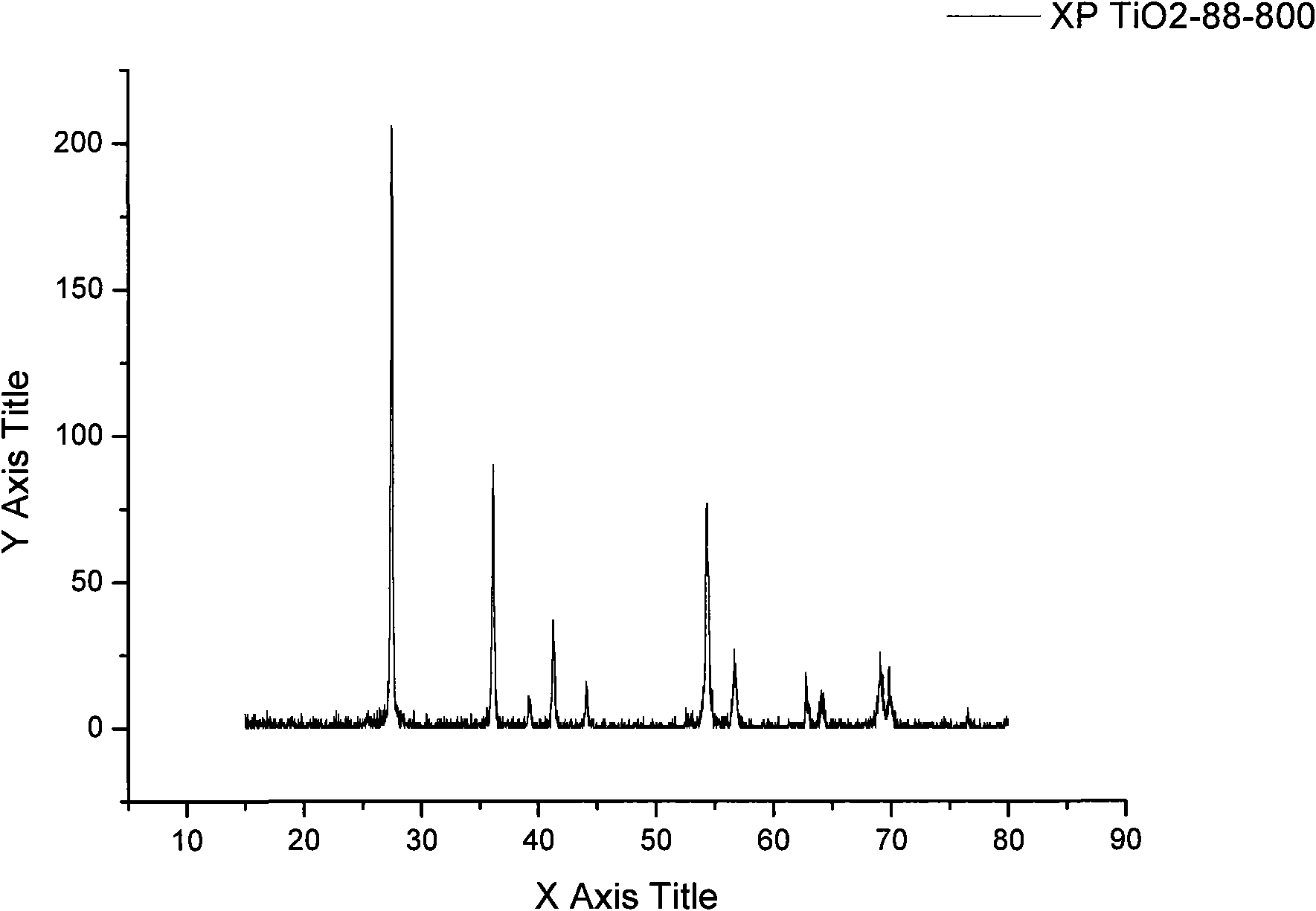

Examples

Embodiment 1

[0083] In this embodiment, the chemical composition of the blast furnace slag used as the raw material is shown in Table 2.

[0084] Table 2

[0085] Component

Content (mass percentage)

TiO 2

~22%

SiO 2

~24%

CaO

~28%

MgO

~8%

al 2 o 3

~13%

FeO / Fe 2 o 3

~2.5%

V 2 o 5

~0.5%

other

~2%

[0086] Before the reaction, the blast furnace slag was screened with a 40-mesh sieve.

[0087] The reaction is carried out in a hydrothermal reactor that can withstand 4MPa and 200°C. Because hydrogen bromide is a corrosive acid, a PTFE gasket needs to be installed on the inner wall of the hydrothermal reactor. The capacity of the reaction kettle is 300mL. Add 149.9g of 40% hydrogen bromide solution and 6.0254g of blast furnace slag into the reaction kettle at room temperature, seal the reaction kettle, raise the temperature to 180°C, maintain it for 4h, and...

Embodiment 2

[0091] The blast furnace slag raw material is first ground and screened through a 325 mesh screen.

[0092] Add 35.2g of 40% hydrogen bromide solution and 8.001g of blast furnace slag into the reactor at room temperature, seal the reactor, heat the reactor to 200°C for 4h, and then cool to room temperature. The reaction product was filtered to obtain a solid precipitate and a filtrate. The main components of the solid precipitate are titanium dioxide and silicon dioxide. The above solid residue is washed and sent to an oven for drying. The final product weighs 3.581g, and the recovery rate of titanium dioxide and silicon dioxide is 44.76%.

[0093]Put 3.570g of the above final product into a 100mL hydrothermal reaction kettle, and add 2.695g of sodium hydroxide and 20mL of water at the same time. Seal the reaction kettle, heat the reaction kettle to 180° C., maintain for 4 hours, cool the reaction kettle to room temperature, and filter the reaction product to obtain a precipi...

Embodiment 3

[0095] The blast furnace slag raw material is first ground and screened through a 325 mesh screen.

[0096] Add 35.2g of 40% hydrogen bromide solution and 8.000g of blast furnace slag into a 300ml hydrothermal reactor at room temperature, seal the reactor, heat the reactor to 200°C for 2 hours, and then cool to room temperature. The reaction product was filtered to obtain a solid precipitate and a filtrate. The main components of the solid precipitate are titanium dioxide and silicon dioxide. The above solid residue is washed and sent to an oven for drying. The final product weighs 3.643g, and the recovery rate of titanium dioxide and silicon dioxide is 45.54%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com