Method for advanced treatment and recycling of petroleum and petrochemical wastewater

A petrochemical wastewater and advanced treatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of high system operation and maintenance costs, water volume cannot be guaranteed, and equipment operation is stable In order to achieve the effects of strong resistance to the impact of sewage water quality changes, intuitive and convenient operation and maintenance, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

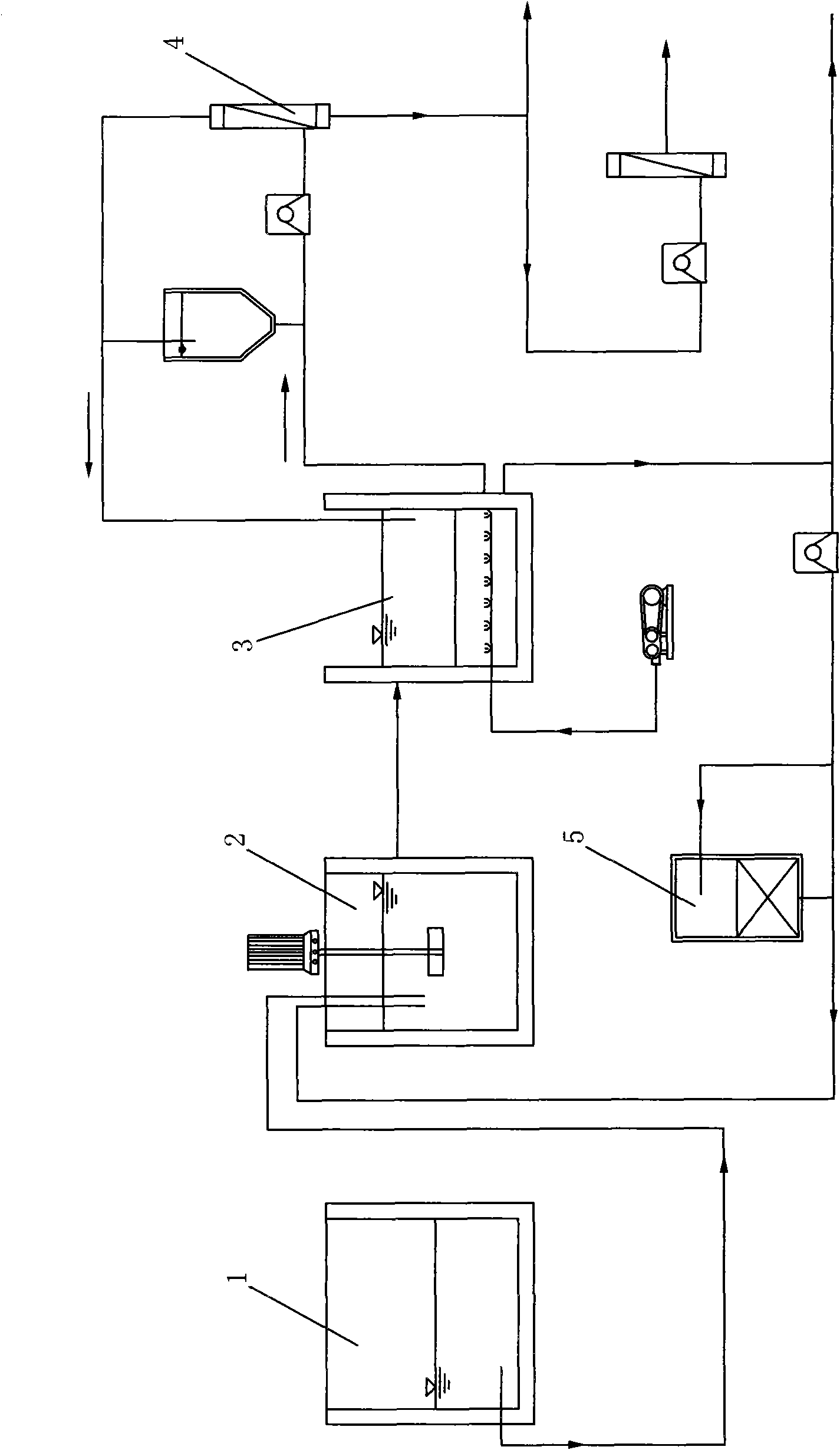

[0026] 1) The effluent (B / C<0.2) after preliminary treatment of refinery sewage enters the regulating tank 1 .

[0027] 2) The sewage is transported from the regulating tank 1 to the anaerobic tank 2 through the water pump, and the sewage entering the anaerobic tank is quickly mixed with the micro-ecological flora in the anaerobic tank by using the stirring device of the anaerobic tank, so that it is basically completely mixed state; after anaerobic treatment, the macromolecular refractory substances in the sewage are transformed into small molecular substances that are easy to degrade and biochemical, improving the biodegradability of sewage. The COD of the anaerobic biological reaction effluent is 100-200mg / L, preferably 120-160mg / L.

[0028] 3) The sewage simply settles after passing through the anaerobic tank, and then enters the aerobic tank 3 for aerobic biochemical treatment. On the one hand, the sludge in the aerobic tank is aerated to ensure the oxygen content in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com