Method for base group modification of low molecular heparin

A low-molecular-weight heparin and modification method technology, which is applied in the field of group modification of natural low-molecular-weight heparin for anticoagulant drugs, can solve the problems of comprehensive utilization, deep processing level and backward technical equipment, high production cost of natural low-molecular-weight heparin, and product toxicity. Large side effects and other problems, to achieve the effect of not prone to thrombocytopenia, stable dose-effect relationship, and long plasma half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

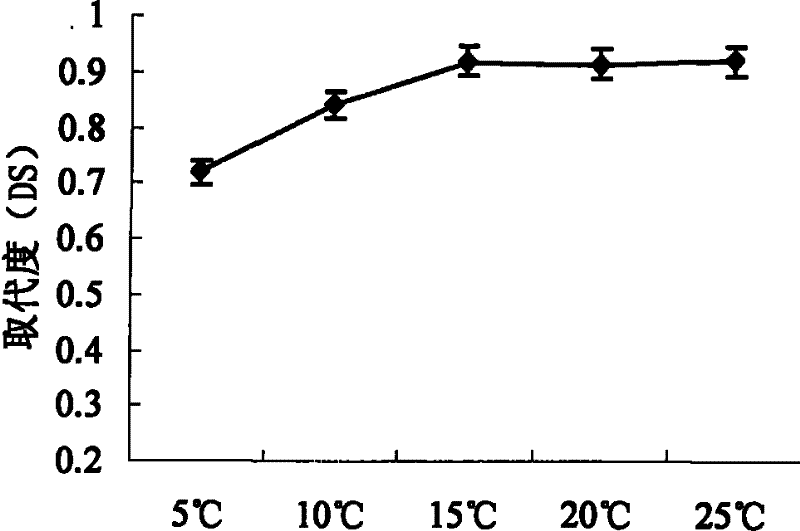

[0016] Embodiment 1, reaction temperature is the important factor that influences degree of substitution in the Wolfom method, at first single factor test is carried out to the range of influence of reaction temperature, other two factors reaction time and esterification reagent ratio are respectively 2h and 1: 1, See the test results figure 1 . Depend on figure 1 It can be seen that with the increase of reaction temperature, the degree of substitution tends to increase continuously, mainly because the increase of temperature makes the functional groups easier to be substituted, so that the degree of substitution of low molecular weight heparin increases, but the degree of substitution does not increase with temperature. The increase of temperature increases continuously, and the degree of substitution decreases when the temperature exceeds 25°C, which is mainly related to the number of functional groups that can be substituted by sulfate groups in low molecular weight hepari...

Embodiment 2

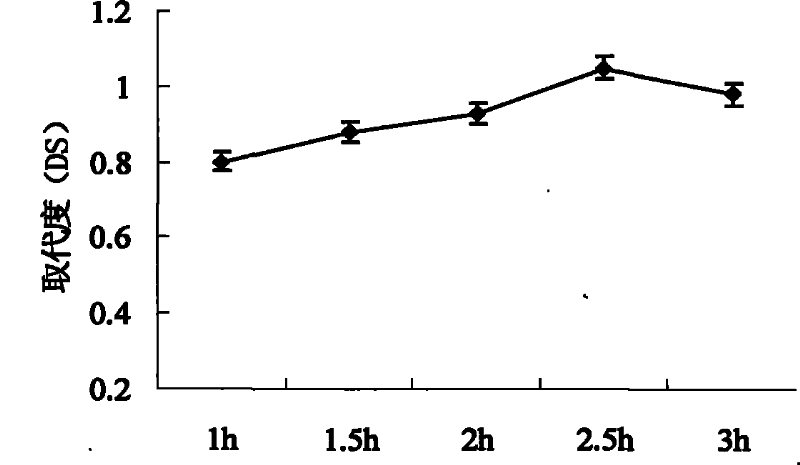

[0017] Embodiment 2, after having carried out the influence of reaction temperature on degree of substitution, continue to carry out experimental analysis to the influence of reaction time, reaction temperature is 15 ℃, and esterification reagent ratio is 1: 1, and test level number is five , the test results see figure 2 . According to the effect of different reaction times on the degree of substitution and figure 2 It can be seen that the degree of substitution increases with the prolongation of the reaction time. But after 2.5 hours, the degree of substitution decreased, which is mainly related to the structure of LMWH. There are three substitutable groups in the main structure of LMWH. After the reaction time is prolonged, the added sulfuric acid group may be replaced by other groups. Substitution, resulting in a decrease in the degree of substitution. So the time is 1h ~ 2.5h is appropriate.

Embodiment 3

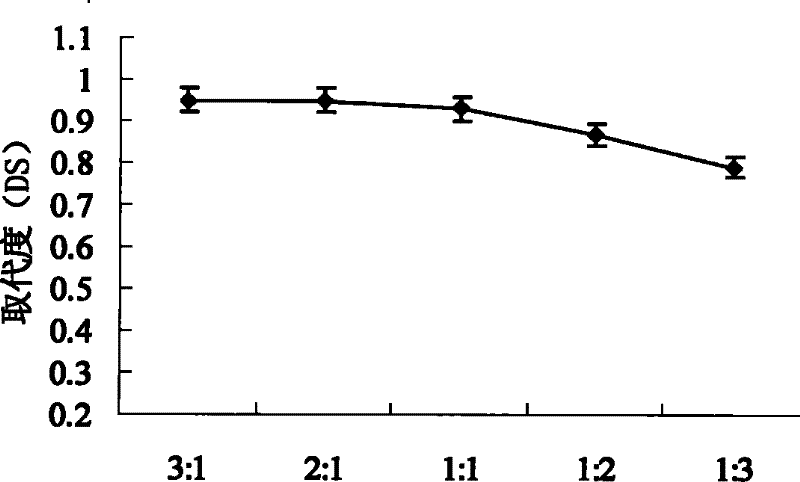

[0018] Embodiment 3, different esterification reagents and their proportions are also an important factor affecting the degree of substitution. During the test, the effect of the ratio of esterification reagents on the degree of substitution in the Wolfom method was studied. The reaction time was 2h, and the reaction temperature was 15°C. see results image 3 . Depend on image 3 It can be seen that with the reduction of the ratio of chlorosulfonic acid and pyridine, the degree of substitution is on a downward trend. The reason is that the proportion of sulfuric acid groups in the esterification reagent is continuously decreasing, and there are fewer groups that can replace the functional groups on the structure of low molecular weight heparin, so that the degree of substitution is also reduced. Declining. The test analysis results show that: 3:1, 2:1, 1:1, 1:2, 1:3 five levels of difference are not significant, the preferred ratio of esterification reagents is 1:1, in consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com