Method for desulfuration by recombination alkylate catalytic distillation

A catalytic distillation and alkylation technology, used in hydrocarbon distillation, petroleum industry, refined hydrocarbon oil, etc., can solve the problems of insufficient boiling point of alkylthiophene derivatives, poor sulfur transfer effect, and separation of low-carbon olefins, etc. Mild operating conditions, small construction investment, and the effect of increasing the boiling point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

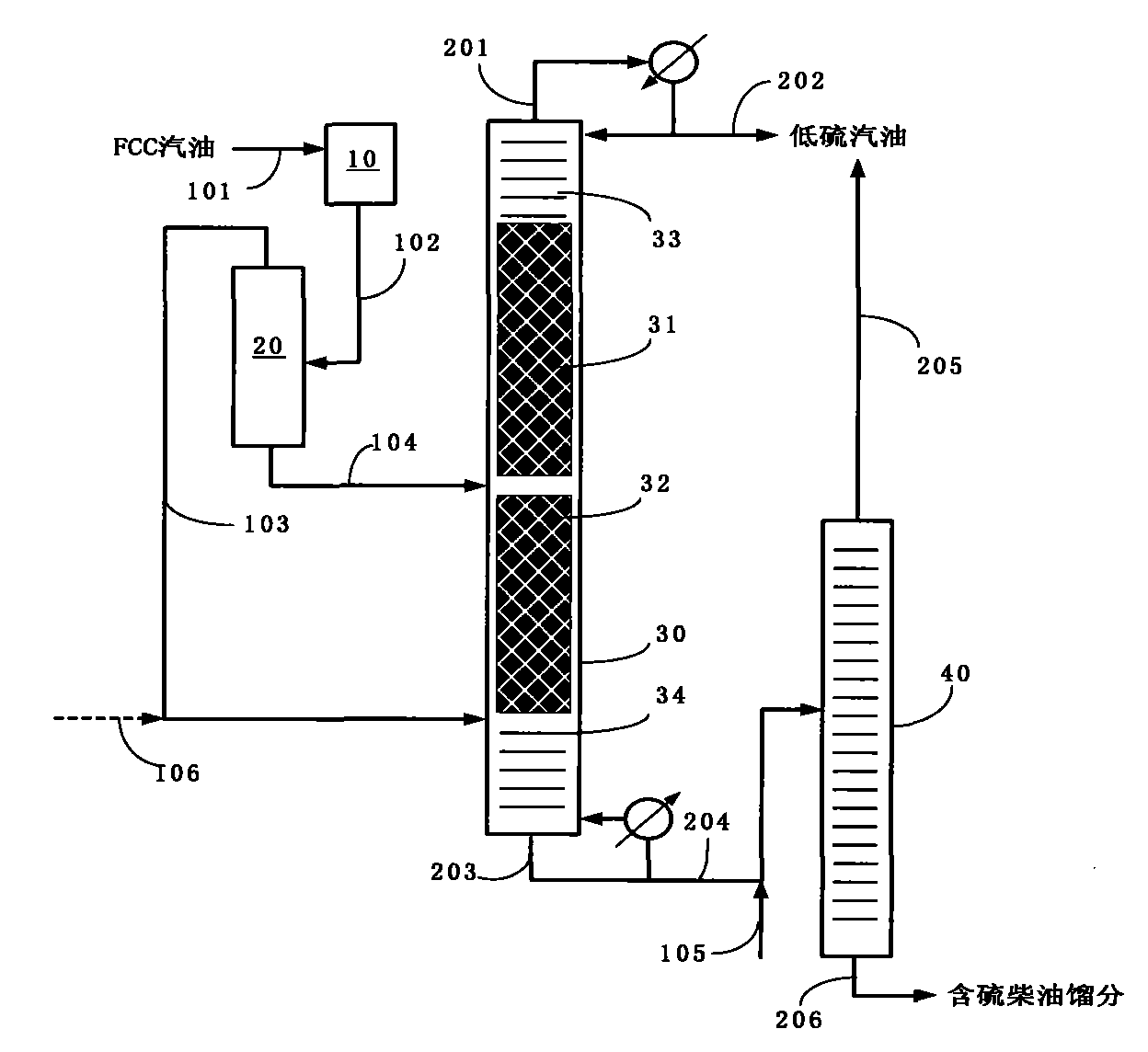

[0029] combined with figure 1 , the process of the present invention is further described.

[0030] The catalytic distillation tower is divided into four parts: an upper reaction section 31 , a lower reaction section 32 , a rectification section 33 and a stripping section 34 . The FCC gasoline raw material is connected to the preprocessor 10 through the pipeline 101 , and then connected to the flash tank 20 through the pipeline 102 . The top of the flash tank is connected to the bottom of the reaction section of the catalytic distillation tower 30 through a pipeline 103 , and the C3-C5 olefin raw material is connected to the bottom of the reaction section through a pipeline 106 . The bottom of the flash tank is connected with the upper reaction section 31 and the lower reaction section 32 of the catalytic distillation column 30 through the pipeline 104 . The top of the tower is connected to the total condenser through the pipeline 201, and the pipeline 202 is connected to th...

Embodiment 2

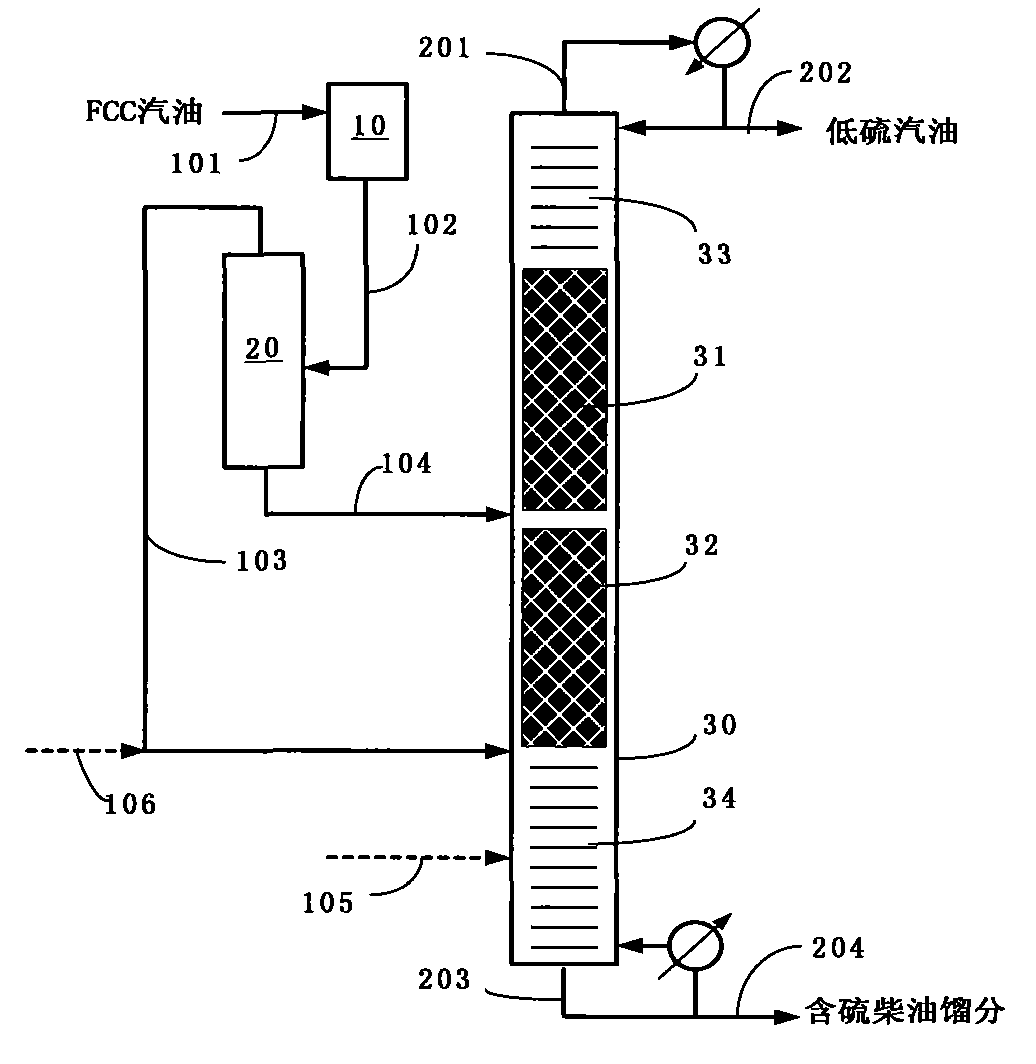

[0034] Knot and attach figure 2 , the process of the present invention is further described.

[0035] The catalytic distillation tower 30 is divided into four parts: an upper reaction section 31 , a lower reaction section 32 , a rectification section 33 and a stripping section 34 . The FCC gasoline raw material is connected to the preprocessor 10 through the pipeline 101 , and then connected to the flash tank 20 through the pipeline 102 . The flash tank is connected to the bottom of the reaction section of the catalytic distillation tower through a pipeline 103 , and the C3-C5 olefin raw material is connected to the bottom of the reaction section through a pipeline 106 . The bottom of the flash tank is connected with the upper reaction section 31 and the lower reaction section 32 of the catalytic distillation column 30 through the pipeline 104 . The top of the tower is connected to the total condenser through the pipeline 201, and the pipeline 202 is connected to the outlet...

Embodiment 3

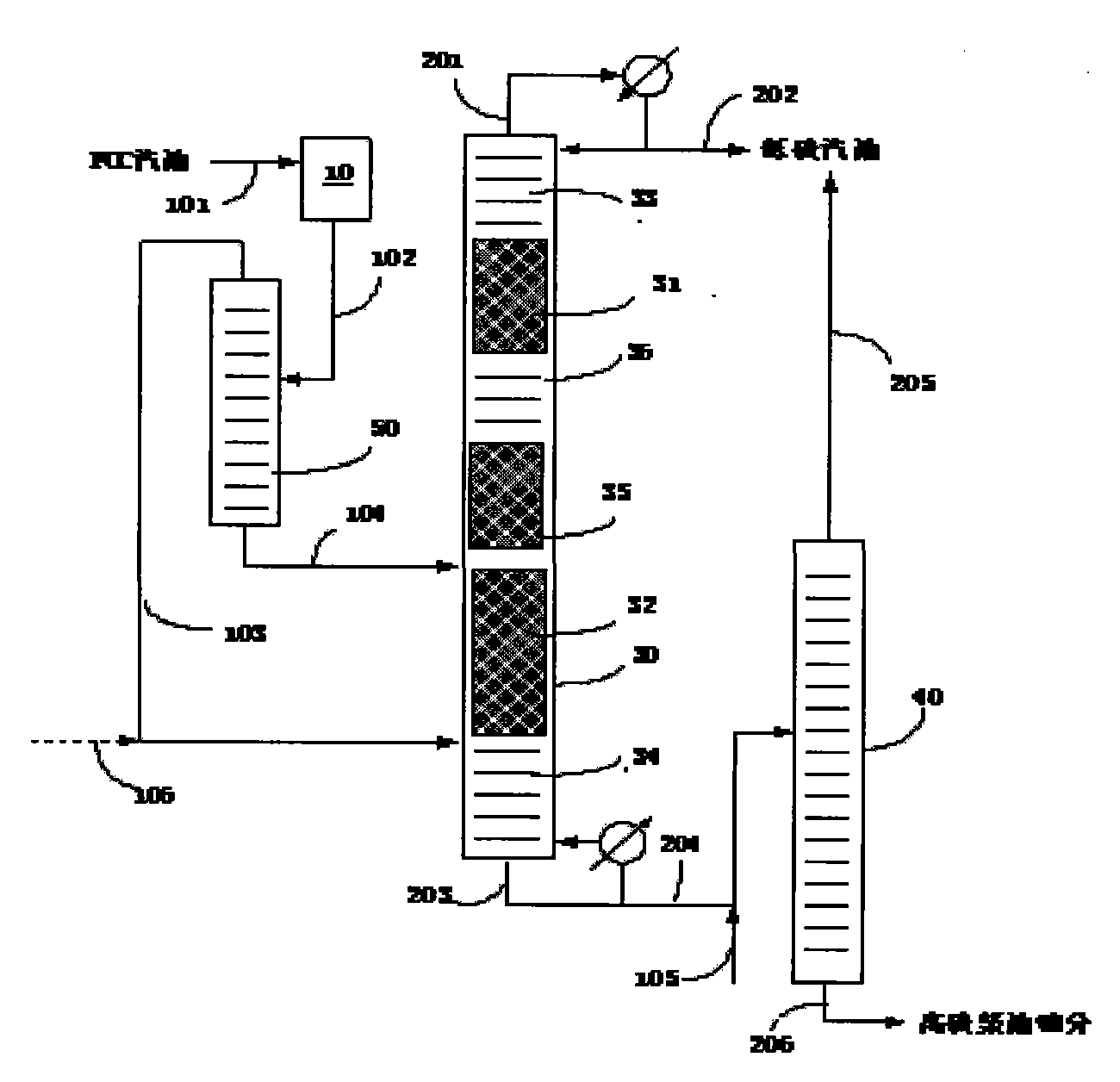

[0039] combined with image 3 , the process of the present invention is further described.

[0040] The catalytic distillation tower is divided into six parts: a rectification section 33 , a stripping section 34 , an upper reaction section 31 , an upper reaction section 2 35 , a lower reaction section 32 , and an intermediate fractionation section 36 . The FCC gasoline raw material is connected to the preprocessor 10 through the pipeline 101 , and then connected to the prefractionator 50 through the pipeline 102 . The top of the prefractionation tower is connected to the bottom of the reaction section of the catalytic distillation tower 30 through a pipeline 103 , and the C3-C5 olefin raw material is connected to the bottom of the reaction section through a pipeline 106 . The bottom of the pre-fractionation tower is connected with the upper reaction section 2 35 and the lower reaction section 32 of the catalytic distillation tower 30 through a pipeline 104 . The top of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com