Blast furnace slag liquid grinding aid and preparation method thereof

A grinding aid and liquid technology, which is applied in the field of blast furnace slag liquid grinding aid and its preparation, can solve problems such as shortage and rising, and achieve the effect of easy purchase of raw materials, improvement of activity index, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

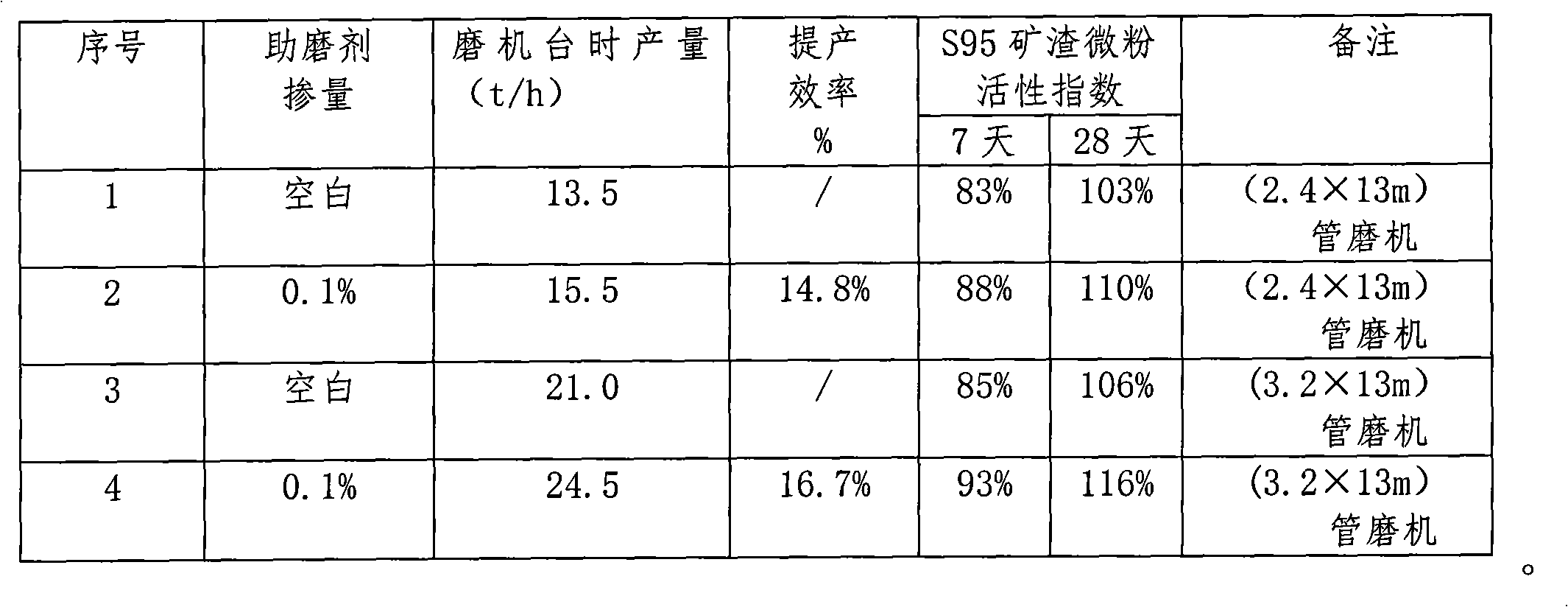

Image

Examples

Embodiment 1

[0013] Embodiment 1: a kind of liquid slag grinding aid, each component ratio is as follows (mass percentage):

[0014] Diethylene glycol 20%

[0015] Sugarcane waste liquid 15%

[0016] Sorbitol 10%

[0017] Glycerin 20%

[0018] Sodium Tripolyphosphate 5%

[0020] The balance is water.

[0021] The preparation process of this liquid slag grinding aid is as follows:

[0022] Inject hot water at 30-40°C into the reactor, add sodium tripolyphosphate and sodium carbonate and stir for 15 minutes, then add sugar cane residue waste liquid and stir for 10 minutes; filter the materials in the reactor with a 150-mesh screen; Add diethylene glycol, sorbitol and glycerin and stir for 20 minutes to obtain a grinding aid product.

Embodiment 2

[0023] Embodiment 2: a kind of slag grinding aid, each component ratio is as follows (mass percentage):

[0024] Diethylene glycol 20%

[0025] Sugarcane waste liquid 10%

[0026] Sorbitol 10%

[0027] Glycerin 20%

[0028] Sodium Tripolyphosphate 1%

[0029] Sodium Carbonate 10%

[0030] The balance is water.

[0031] Its preparation process is with embodiment 1.

Embodiment 3

[0032] Embodiment 3: a kind of liquid cement grinding aid, each component ratio is as follows (mass percentage):

[0033] Diethylene glycol 10%

[0034] Sugarcane waste liquid 10%

[0035] Sorbitol 10%

[0036] Glycerin 20%

[0037] Sodium Tripolyphosphate 5%

[0038] Sodium Carbonate 5%

[0039] Sodium dodecylbenzenesulfonate 5%

[0040] Ethylene glycol 5%

[0041] The balance is water.

[0042] The preparation method of this liquid cement grinding aid is as follows:

[0043] Inject hot water at 30-40°C into the reaction kettle, add sodium tripolyphosphate and sodium carbonate and stir for 15 minutes, then add sugar cane residue waste liquid and stir for 10 minutes, then add ethylene glycol and sodium dodecylbenzenesulfonate Stir evenly; filter the material in the reaction kettle with a 150-mesh screen; add diethylene glycol, sorbitol, and glycerin and stir for 20 minutes to obtain a grinding aid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com