A kind of desulfurization and denitrification equipment and method

A desulfurization and denitrification equipment technology, applied in the field of desulfurization and denitrification, can solve problems affecting water source safety, sulfur dioxide and nitrogen oxide entry, environmental pollution, etc., and achieve the effects of simple operation, reduced loss, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

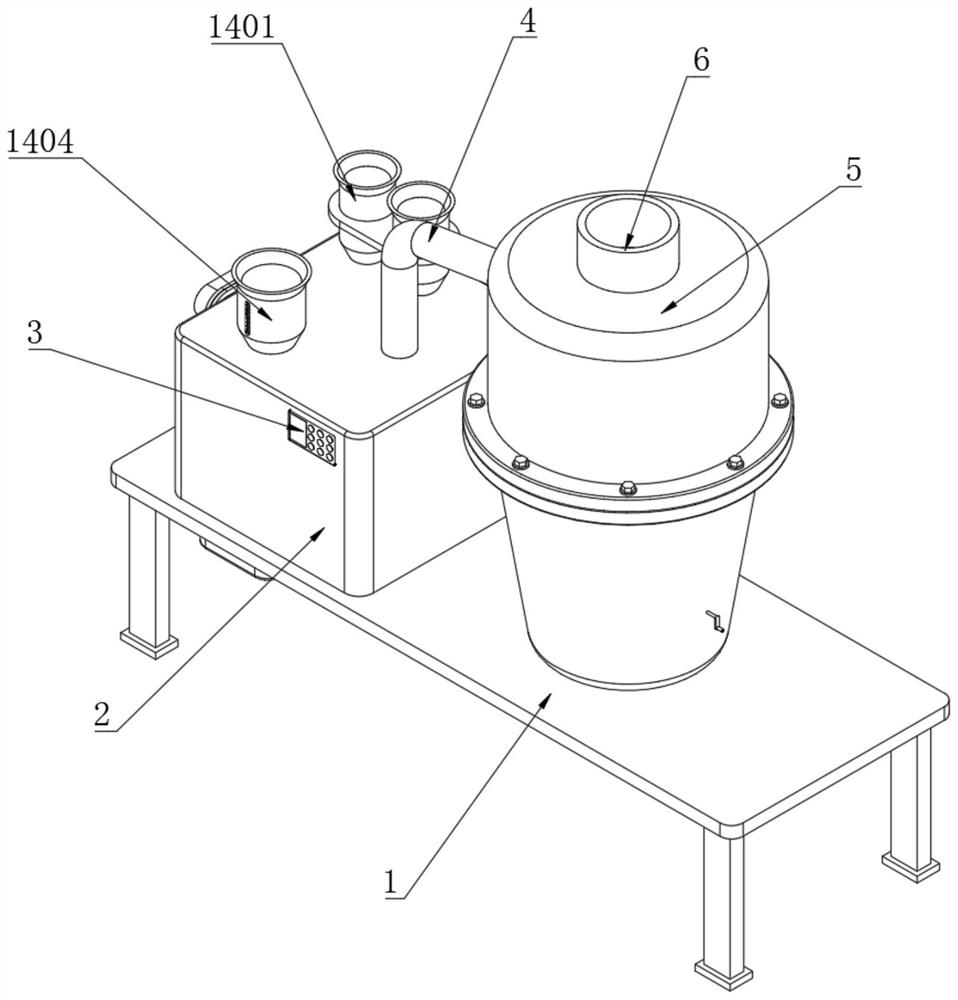

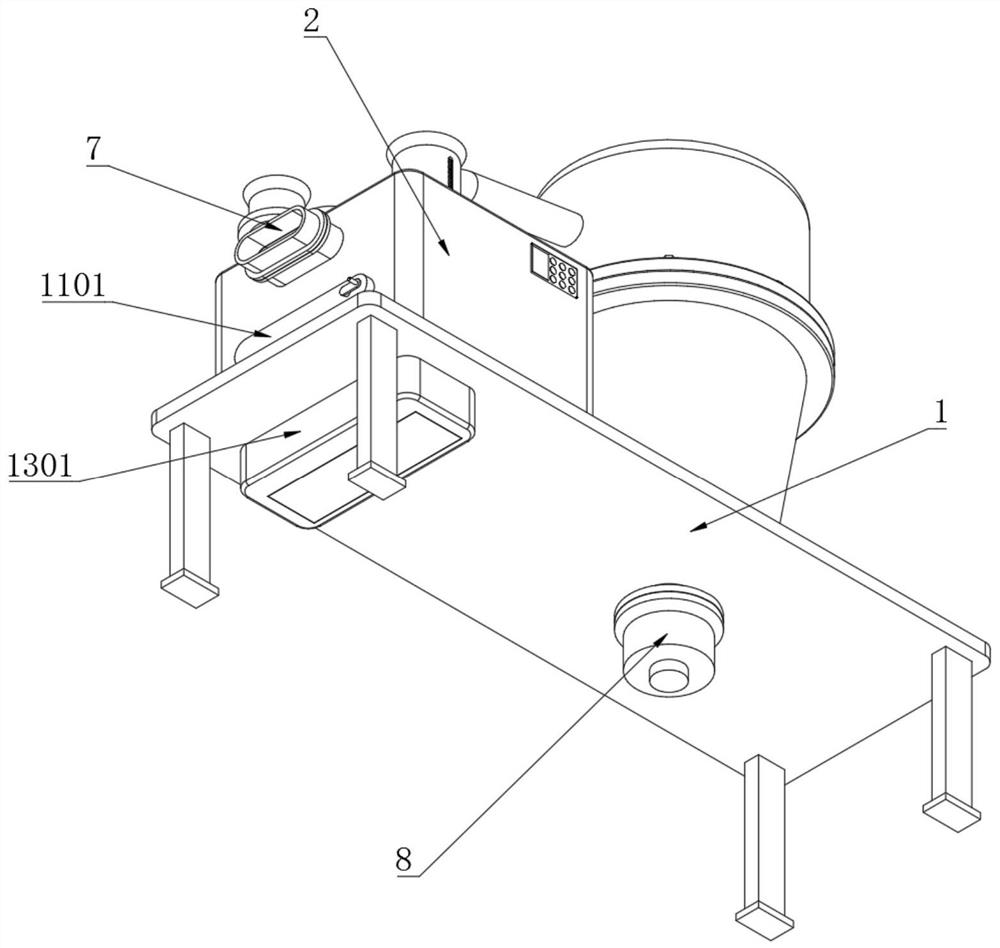

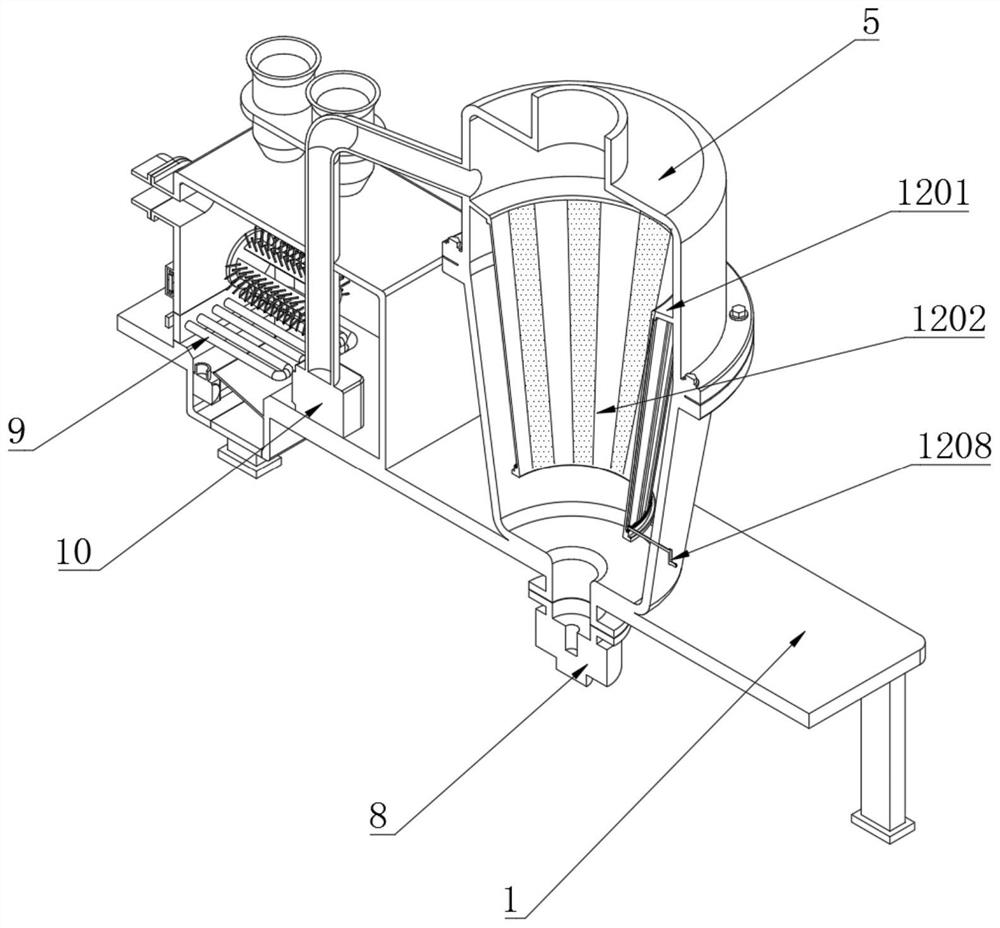

[0054] Embodiment 1: as Figure 1-11 As shown, the present invention provides a technical solution, a kind of desulfurization and denitrification equipment, including a placement rack 1, a transfer box 2 is installed on the top of the placement rack 1, a control switch 3 is embedded and connected to one end of the transfer box 2, and a control switch 3 is connected to the top of the transfer box 2. The conveying pipe 4, the top of the placement frame 1 corresponds to the position on the side of the transfer box 2, and the swirl scrubber 5 is installed through it. The top of the swirl scrubber 5 is connected to the outlet pipe 6, and the other end of the transfer box 2 is connected to the waste water inlet pipe. 7. The bottom end of the swirl scrubber 5 is connected with a sewage outlet 8, a heating pipe 9 is installed on the inner wall of one end of the transfer box 2, and a waste water extraction pump 10 is installed on the inner wall of the bottom end of the transfer box 2; ...

Embodiment 2

[0066] Embodiment 2: as Figure 12 As shown, the present invention provides a technical solution, a process for using desulfurization and denitrification equipment, which specifically includes the following steps:

[0067] S1. Wastewater heating: transfer the wastewater to be treated to the transfer box for heating;

[0068] S2. Preliminary separation: use a separation extraction pump and a separation net to separate the larger solid impurities contained in the wastewater;

[0069] S3, adding reactant: adding sodium sulfide, ammonium chloride and ammonia water to the heated wastewater;

[0070] S4. Cyclone separation: the wastewater is then transferred to the cyclone scrubber, and the solid sediment and wastewater are separated by cyclone;

[0071] S5. Discharge detection: the separated solid sediment and waste water are discharged separately, and the contents of sulfur dioxide and nitrogen oxides in the discharged waste water are detected.

[0072] According to the above t...

Embodiment 3

[0074] Embodiment 3: as Figure 12 As shown, the present invention provides a technical solution, a process for using desulfurization and denitrification equipment, which specifically includes the following steps:

[0075] S1. Wastewater heating: transfer the wastewater to be treated to the transfer box for heating;

[0076] S2. Preliminary separation: use a separation extraction pump and a separation net to separate the larger solid impurities contained in the wastewater;

[0077] S3, adding reactant: adding sodium sulfide, ammonium chloride and ammonia water to the heated wastewater;

[0078] S4. Cyclone separation: the wastewater is then transferred to the cyclone scrubber, and the solid sediment and wastewater are separated by cyclone;

[0079] S5. Discharge detection: the separated solid sediment and waste water are discharged separately, and the contents of sulfur dioxide and nitrogen oxides in the discharged waste water are detected.

[0080] According to the above t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com