Method for determining fragrance stabilizing capacity of tobacco humectant on additional flavors in cut tobaccos

A humectant and fragrance technology, applied in the field of food science, can solve the problems of humectants that have not been reported, and achieve the effects of fast and accurate fragrance fixing ability, simple process, and fast analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

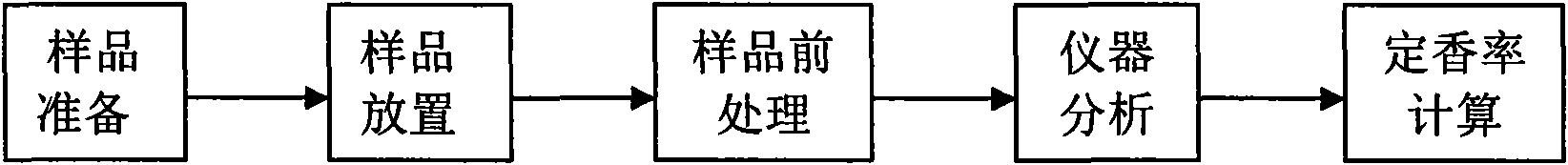

Method used

Image

Examples

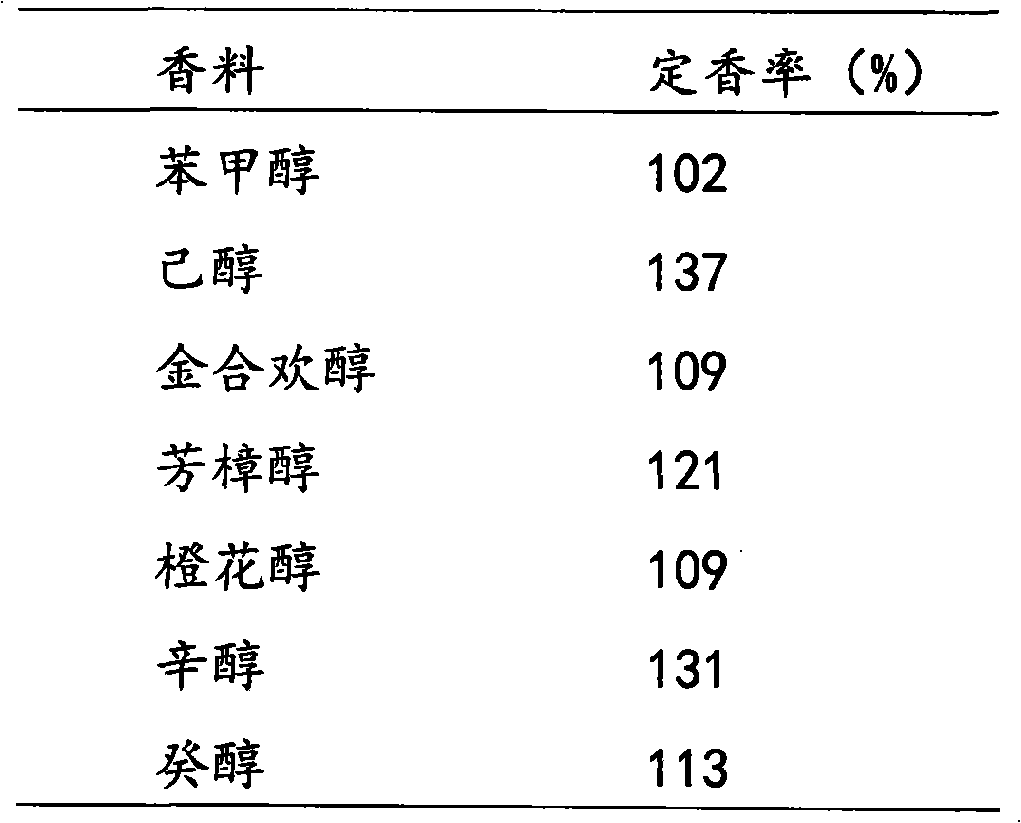

Embodiment 1

[0041] 1. Take two equal parts of shredded tobacco with a mass of 7.982g and an alcohol flavor content of about 150ppm, and add humectant A (for example: hyaluronic acid 1 / 10,000 aqueous solution) with a mass percentage of 1 / 10000 (cut tobacco) to one part , and ensure that the humectant is evenly distributed;

[0042] 2. Place the samples obtained in 1 in a constant temperature and humidity chamber (22±2°C, RH 60±5%) sealed for 48 hours, and then completely open for 8 hours;

[0043] 3. Use 20ml of dichloromethane solution containing 150ppm phenylethyl acetate (chromatographically pure) to ultrasonically extract the shredded tobacco for 35 minutes, and filter it through a 0.45um microporous membrane for subsequent use;

[0044] 4. Gas chromatography / mass spectrometry conditions:

[0045] Chromatographic column: HP-5 (5% phenylpolysiloxane) capillary column 60m×0.20mm×0.50μm;

[0046] Injection port temperature: 250°C;

[0047] Programmed temperature rise: 70°C, keep for 1m...

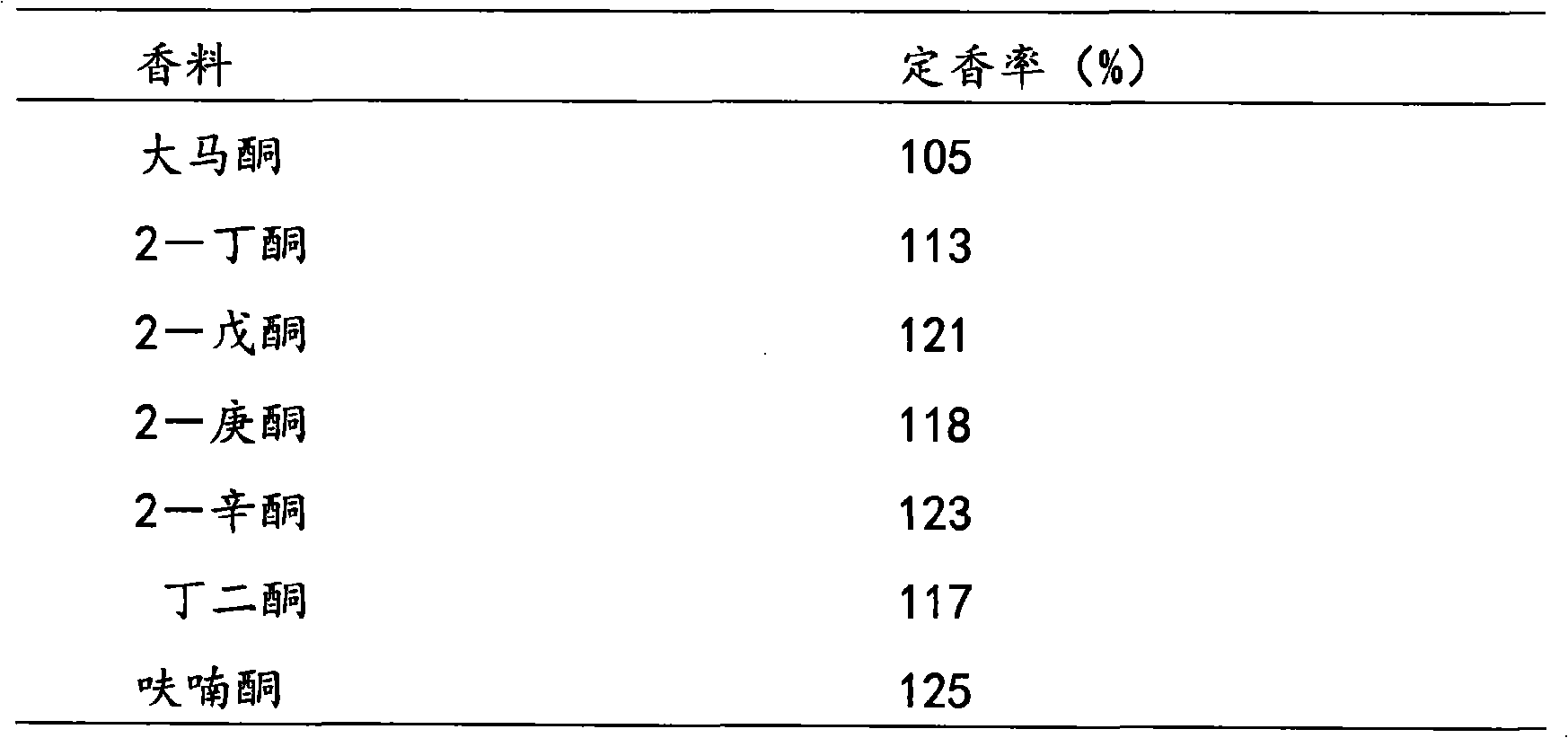

Embodiment 2

[0055] 1. Take two equal portions of 8.597g shredded tobacco with a mass of about 100ppm of ketone flavoring, one of which is added with humectant B with a mass percentage of 5 / 1000 (cut tobacco), and ensure that the humectant is evenly distributed;

[0056] 2. Place the samples obtained in 1 in a constant temperature and humidity chamber (22±2°C, RH 60±5%) sealed for 72 hours, and then completely open for 6 hours;

[0057] 3. Use 20ml of dichloromethane solution containing 100ppm phenylethyl acetate (chromatographically pure) to ultrasonically extract the shredded tobacco for 40 minutes, and filter it through a 0.45um microporous membrane for subsequent use;

[0058] 4. Gas chromatography / mass spectrometry conditions:

[0059] Chromatographic column: DB-5 quartz elastic capillary column (30m×0.25mm×0.25mm Inlet temperature: 250°C;

[0060] Programmed temperature rise: 60°C, keep for 1min; increase to 280°C at a rate of 3°C / min, keep for 40min;

[0061] Carrier gas: helium, ...

Embodiment 3

[0068] 1. Take two equal parts of shredded tobacco with a mass of 8.127g and an ester flavor content of about 167ppm, one of which is added with humectant C with a mass percentage of 1 / 5000 (cut tobacco), and ensure that the humectant is evenly distributed;

[0069] 2. Place the samples obtained in 1 in a constant temperature and humidity chamber (22±2°C, RH 60±5%) sealed for 60 hours, and then completely open for 10 hours;

[0070] 3. Use 20ml of dichloromethane solution containing 150ppm phenylethyl acetate (chromatographically pure) to ultrasonically extract the shredded tobacco for 30 minutes, and filter it through a 0.45um microporous membrane for subsequent use;

[0071] 4. Gas chromatography / mass spectrometry conditions:

[0072] Chromatographic column: HP-5 capillary column 50m×0.20mm×0.50μm;

[0073] Injection port temperature: 250°C;

[0074] Programmed temperature rise: 60°C, keep for 1min; increase to 270°C at a rate of 3°C / min, keep for 40min;

[0075] Carrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com