Semiconductor element isolating structure and forming method thereof

A technology of component isolation and isolation structure, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as short circuit and integrated circuit failure, and achieve the effect of preventing bridging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

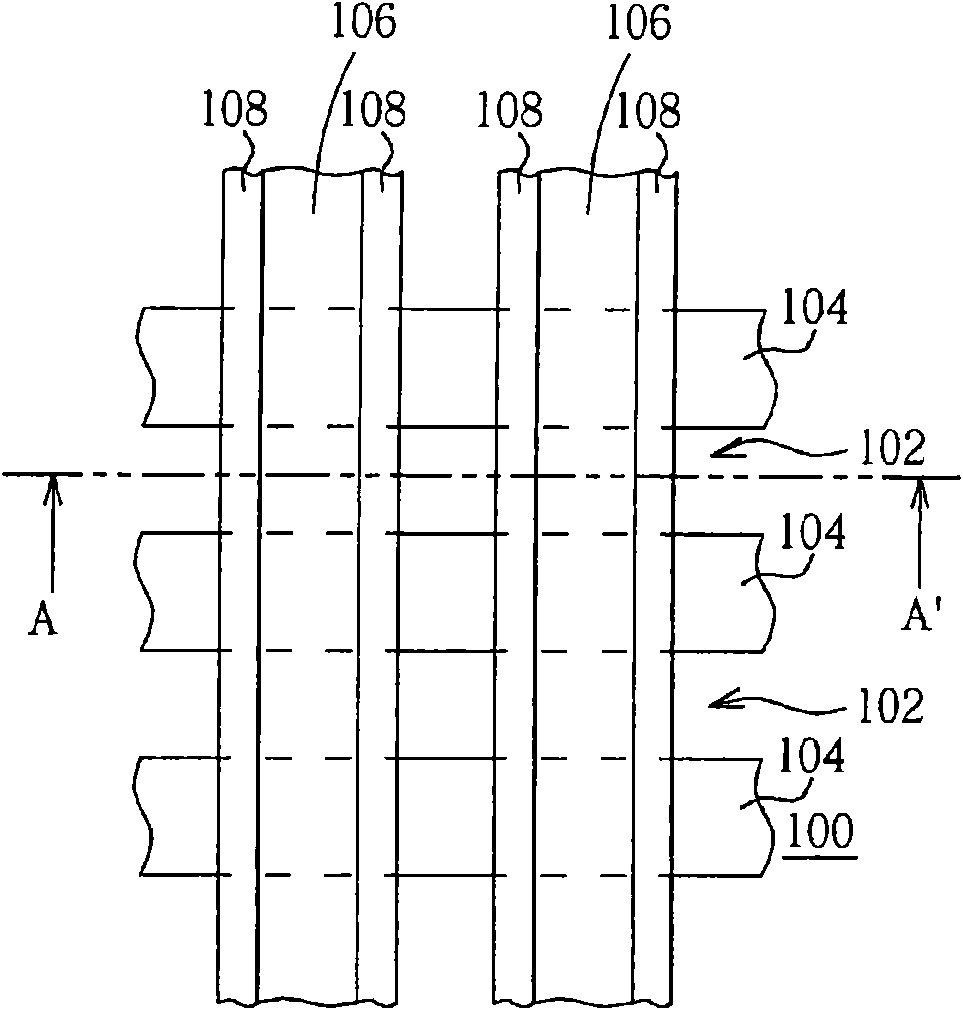

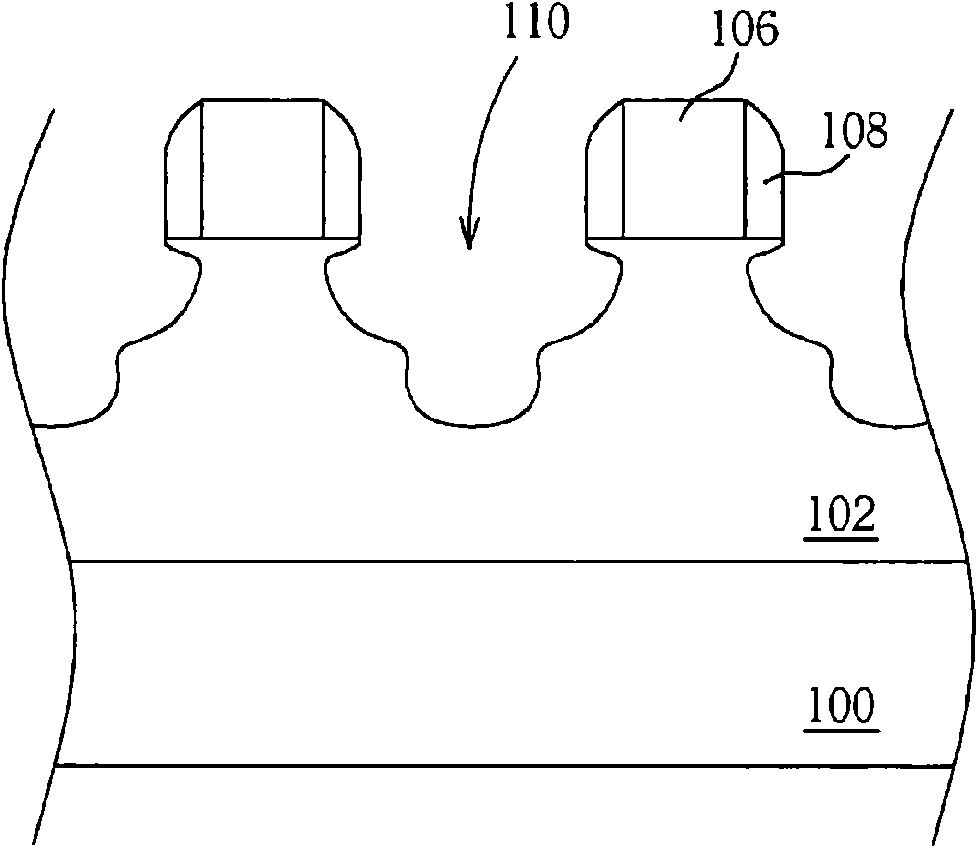

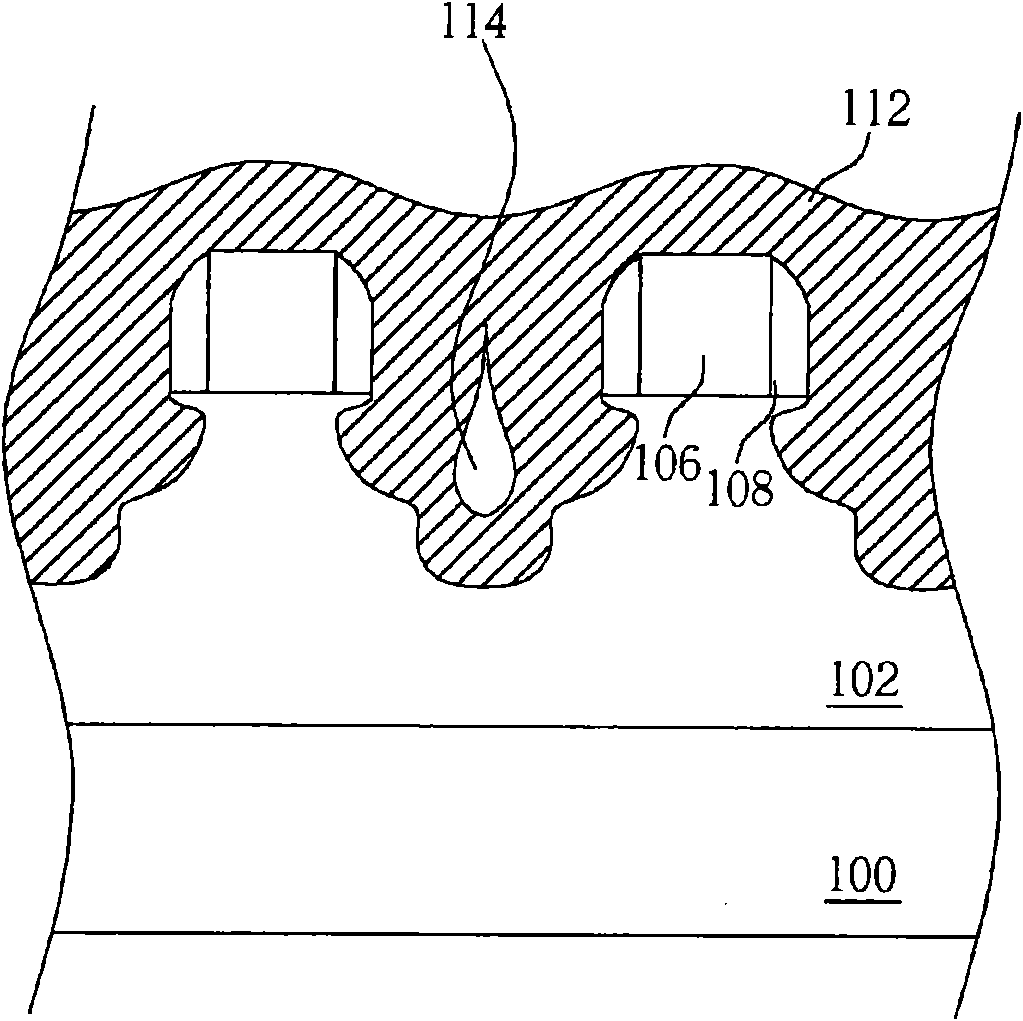

[0027] Please refer to Figure 4 to Figure 9 , Figure 4 It is a semiconductor element of a preferred embodiment of the present invention, such as a dynamic random access memory (DRAM) storage unit (memory cell), a schematic top view of the layout, Figure 5 to Figure 9 For a preferred embodiment of the present invention along Figure 4 Schematic diagram of the formation method of the semiconductor element isolation structure of the BB' line. Such as Figure 4 and Figure 5 As shown, first, a substrate 200 is provided, such as a silicon wafer or a silicon-on-insulator substrate. The substrate 200 includes at least one shallow trench isolation structure 202 and a plurality of gate structures 204 disposed on the shallow trench isolation structure 202 and the substrate 200, wherein the shallow trench isolation structure 202 defines a plurality of active regions 206, and The shallow trench isolation structure 202 is used to isolate each active region 206 . In addition, space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com