Nanotube and carbon layer nanostructured composites

A nanostructure composite and nanostructure technology, applied in nanostructure manufacturing, nanocarbon, carbon nanotubes, etc., can solve the problems of complex nanotube manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

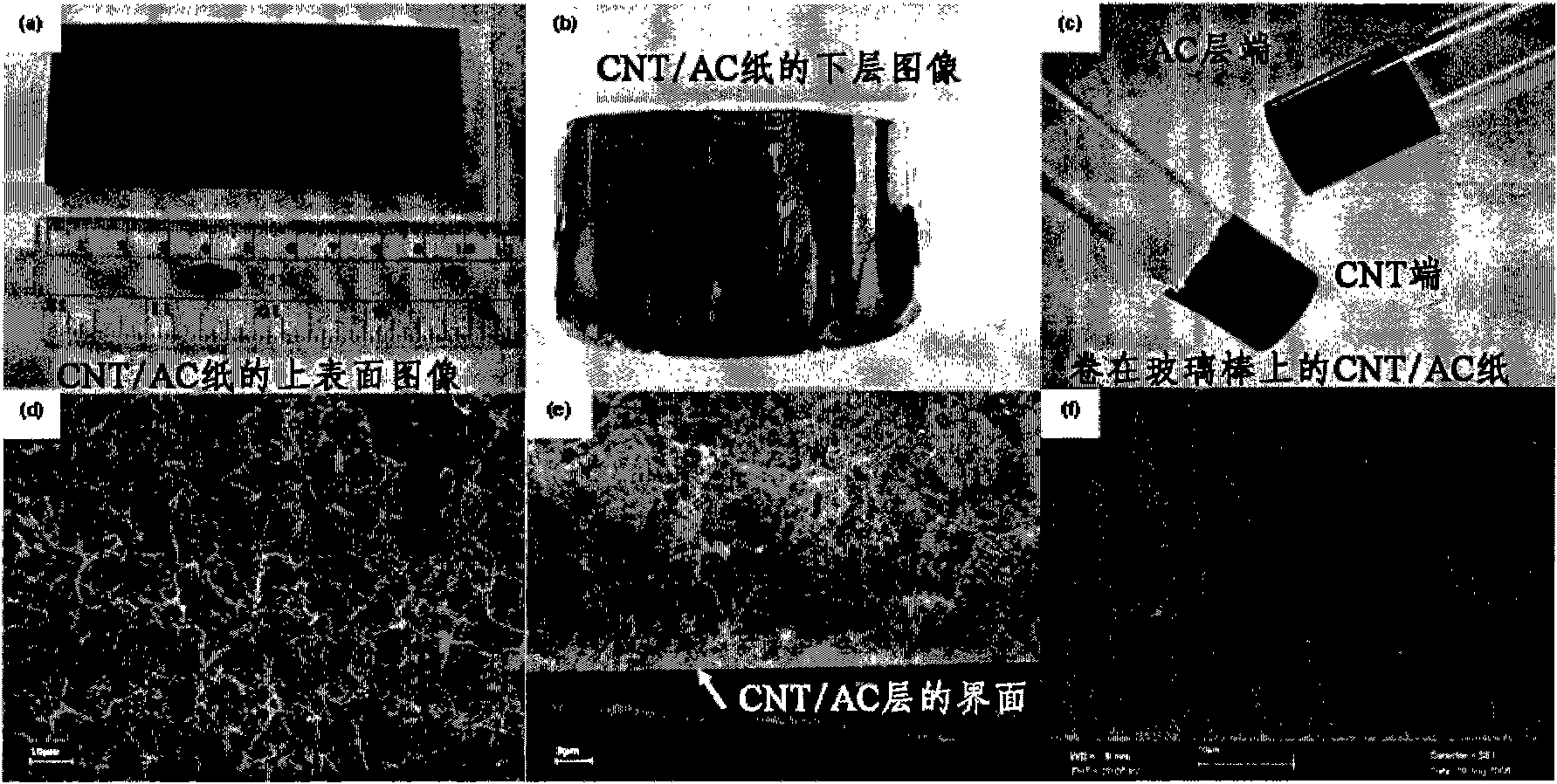

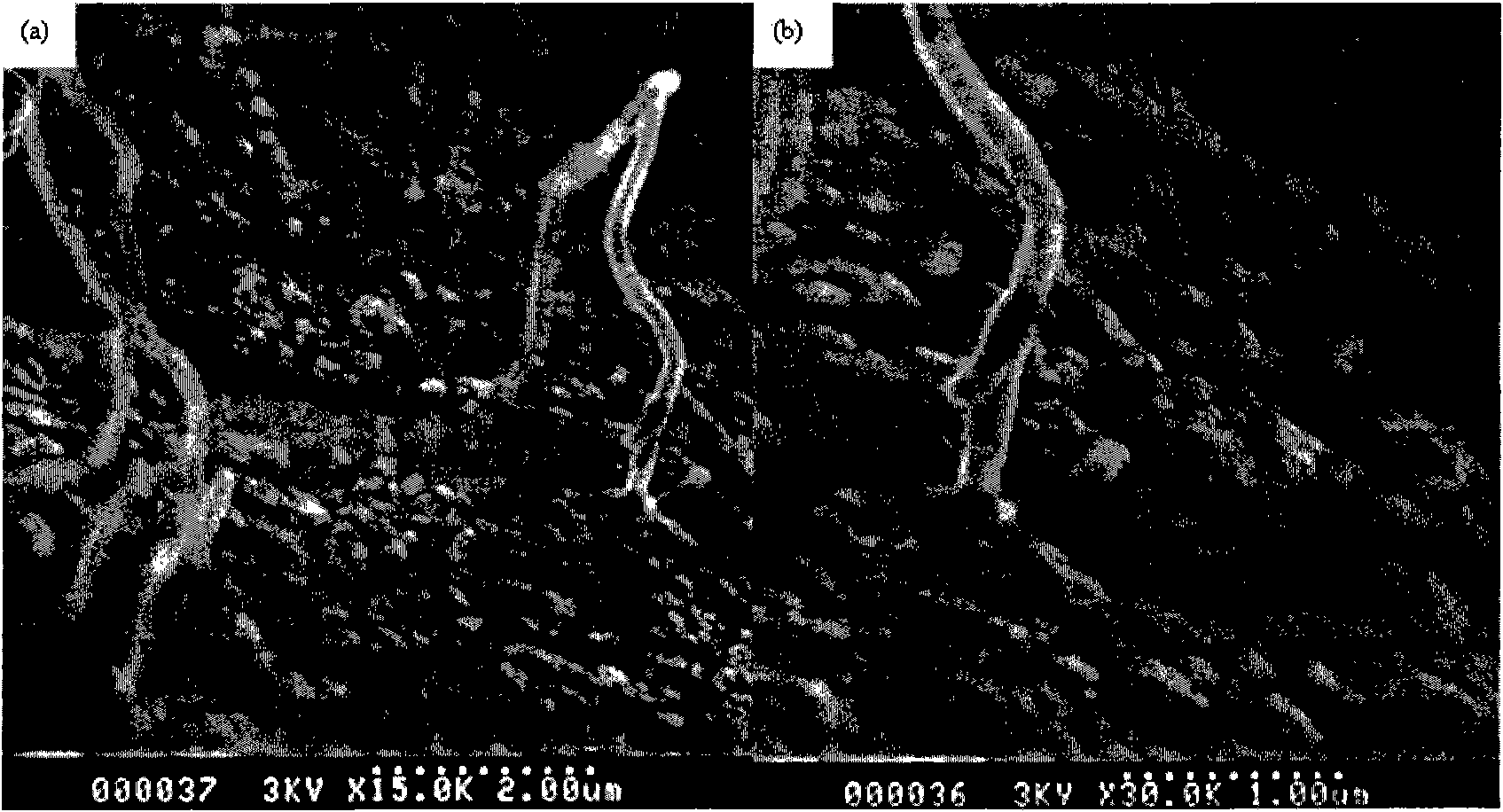

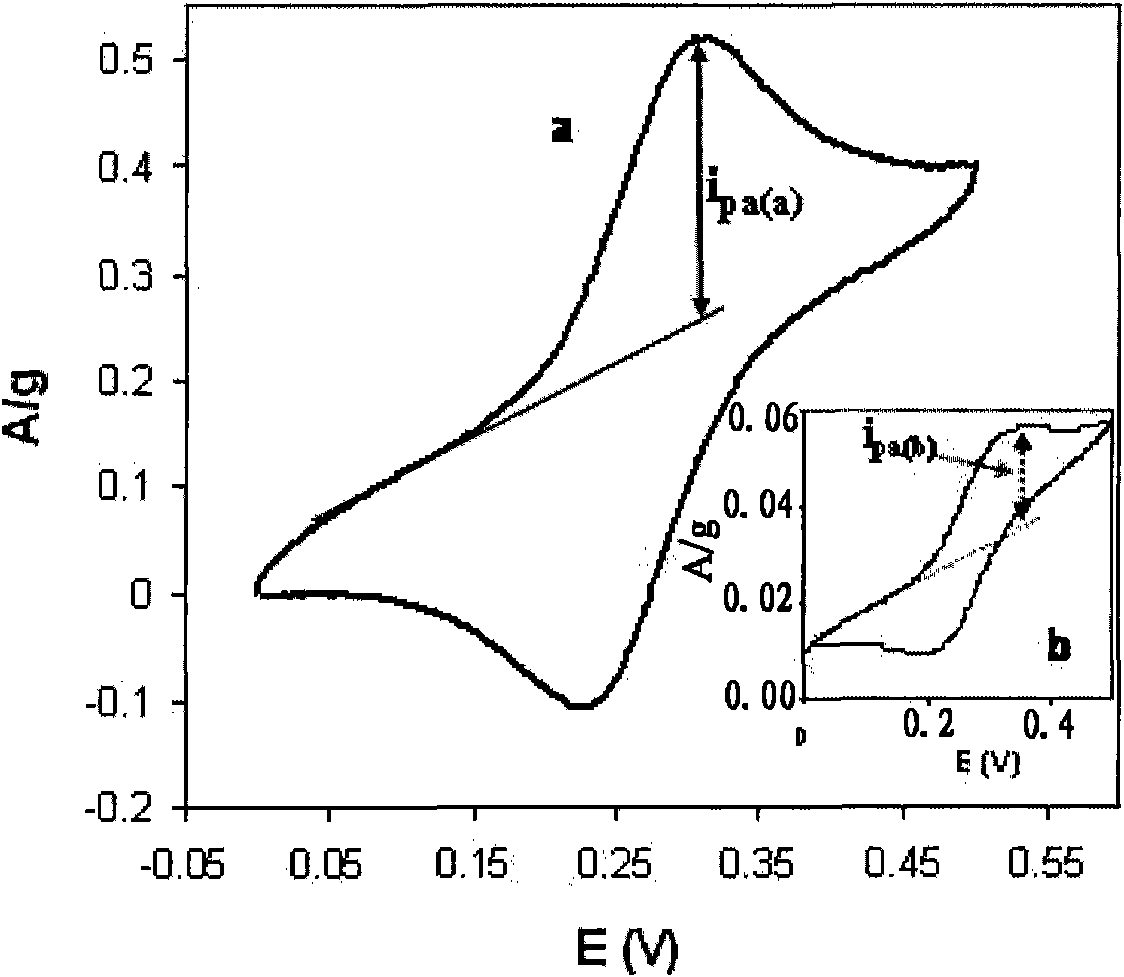

Image

Examples

Embodiment

[0136] Using a commercially available spin coater (Laurell Tech), the catalyst (Fe(III) / TS / DBS or / PS was spin-coated from a 10% (w / w) Fe(III) TS / ethanol solution at 1000 rpm) to A thin film of 1μm is formed on a quartz plate (3mm thick, 4×10cm). Then, in a conventional heating furnace at 60-80℃, the catalyst film is annealed for 5 minutes until the film color becomes dark yellow, indicating that the ethanol solvent has evaporated .

[0137] Commercially available thermal CVD system (Atomate) is used to enable the software to control gas flow, furnace temperature and deposition time for chemical vapor deposition. Rinse the system with argon (Ar, 150ml / min) for 30 minutes, and then use Ar (200ml / min) and H 2 (20ml / min) The temperature of the furnace is increased under the air flow to 500°C. Then, the furnace temperature is maintained at 500° C. for 10 minutes to reduce the iron (III) into iron nanoparticles. Then increase the temperature to 800 ℃, and then use the gas flow rate Ar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com