Controlled-bactericide-release fruit and vegetable preservative packaging composite film, preparation method thereof, and use thereof

A technology for preservation and controlled release of fruits and vegetables, applied in the directions of preservation, application, and packaging of fruits and vegetables, it can solve the problems of insufficient controlled release, difficulty in producing sufficient amounts of sulfur dioxide, etc., to inhibit further erosion, prevent bacterial growth, The effect of delaying ripening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

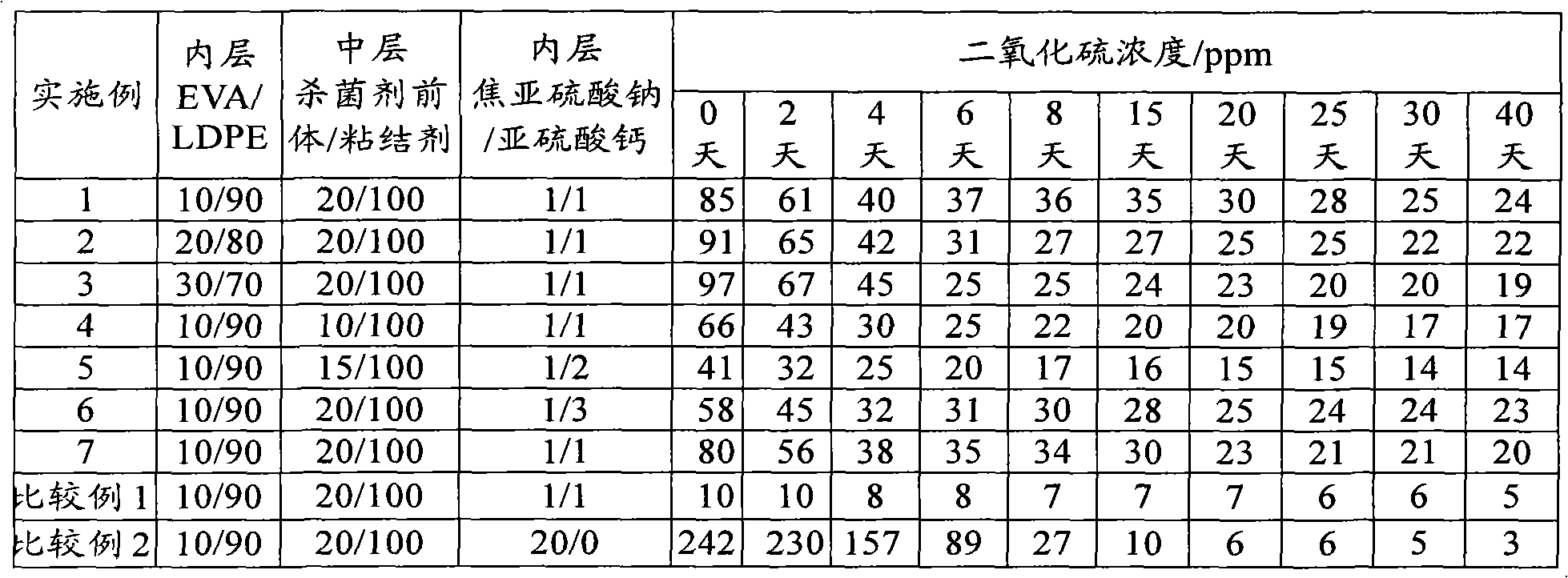

Examples

preparation example Construction

[0049] Another specific embodiment of the present invention provides a method for preparing the composite film for fresh-keeping packaging of fruits and vegetables, including:

[0050] Step (1): A certain amount of low-density polyethylene resin and polyethylene vinyl acetate resin are melt-blended in an extruder, then blown into a film with a thickness of 20 to 40 microns, and optionally corona treated, as the inner layer of the fruit and vegetable fresh-keeping packaging composite film;

[0051] Step (2): The thickness is 10-20 microns, the moisture permeability is less than 10ml / (m 2 day·atm) selected from the group consisting of low-density polyethylene, low-density polyethylene and linear low-density polyethylene, high-density polyethylene, medium-density polyethylene blended modified resin film, or biaxially oriented polypropylene The non-polar film in carries out corona treatment, as the outer layer of described fruit and vegetable fresh-keeping packaging composite fil...

Embodiment 1

[0079] The fruit and vegetable fresh-keeping packaging composite film with controlled release of bactericide of embodiment 1 is prepared by the following method:

[0080] Step 1. Buy 10-20 microns thick water vapor transmission rate less than 10ml / (m) on the market 2 day · atm) of BOPP film, corona treatment, spare.

[0081] Step 2. Melt and blend 900g of LDPE resin and 100g of EVA resin in a twin-screw extruder, then blow mold it into a film with a thickness of 20 to 40 microns, and perform corona treatment for subsequent use.

[0082] Step 3. Take 90g of solvent-based two-component polyurethane binder (component A), add a mixture of 10g sodium metabisulfite and 10g calcium sulfite, stir evenly, then add 10g of polyurethane component B (crosslinking agent), mix 5min.

[0083] Step 4. carry out dry compounding to the BOPP film (outer layer film) after corona treatment and the LDPE / EVA film (inner layer film) obtained by step 2 with the binding agent that step 3 obtains, obta...

preparation Embodiment 2

[0086] The difference from Preparation Example 1 is that in step 2, 800g of LDPE resin and 200g of EVA resin are melt-blended in a twin-screw extruder, and then blown into a film with a thickness of 20-40 microns, and subjected to corona treatment for future use. The rest are the same, make a composite fresh-keeping packaging film, add the same fruit simulant, and measure the concentration of the fungicide produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com