Sonochemistry method for preparing AgSbTe2 thermoelectric compound powder

An ultrasonic chemistry and compound technology, applied in chemical instruments and methods, selenium/tellurium compounds, inorganic chemistry, etc., can solve the problems of polycrystalline materials with different phases, microstructures and properties, single compounds, and long reaction cycles, etc. The raw materials are cheap and easy to obtain, the process is simple and easy to control, and the reaction time is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

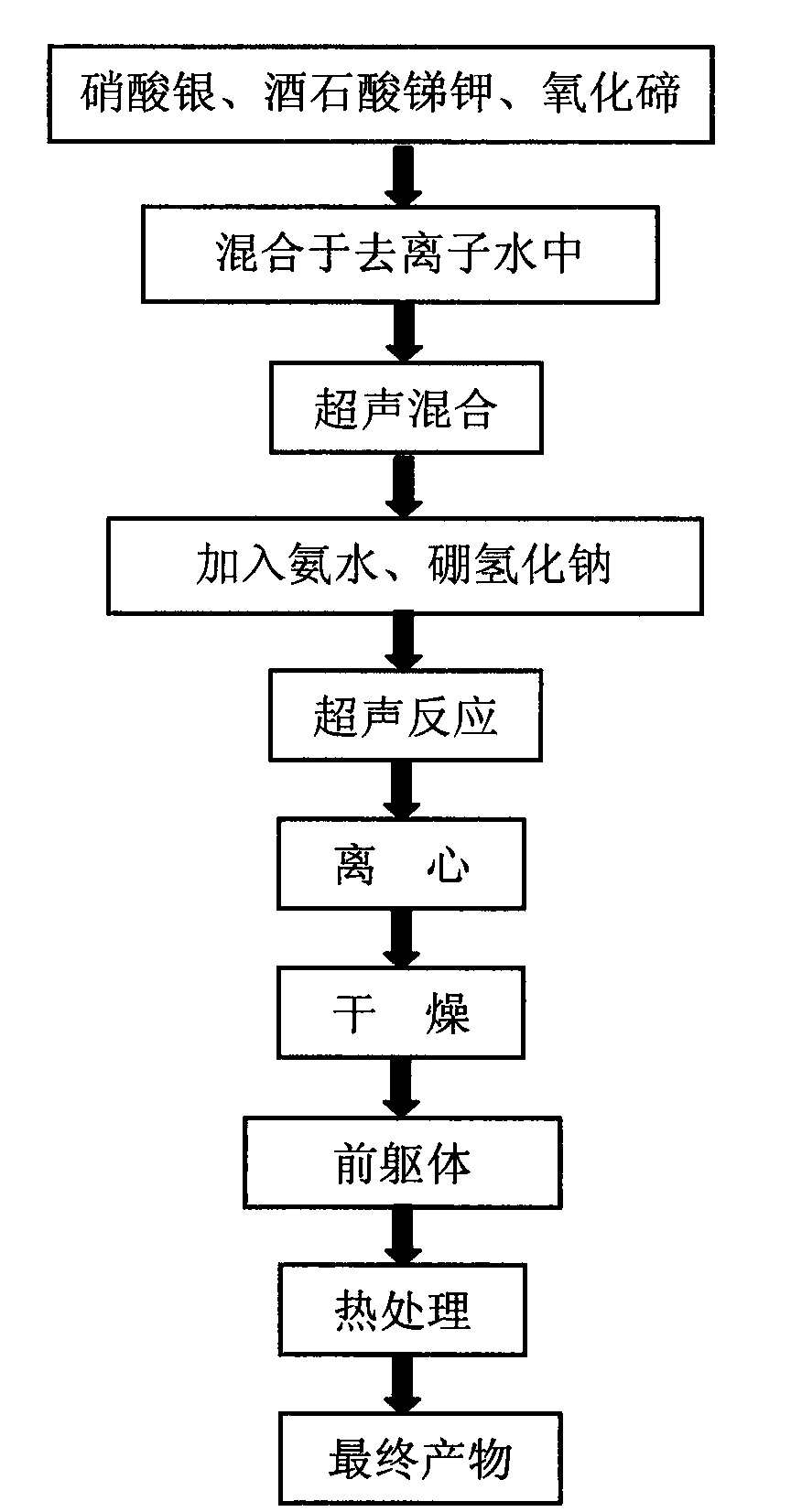

[0024] Such as figure 1 As shown, AgSbTe 2 The sonochemical preparation method of thermoelectric compound powder, it comprises the following steps:

[0025] 1) According to deionized water: AgNO 3 Ag in + : C 4 h 4 KO 7 Sb 1 / 2H 2 Sb in O 3+ : TeO 2 Te in 4+ The ratio is 1L: 0.0166mol: 0.0212mol: 0.04mol, deionized water, AgNO 3 、C 4 h 4 KO 7 Sb 1 / 2H 2 O and TeO 2 ,spare;

[0026] Deionized water was used as solvent, followed by analytically pure AgNO 3 、C 4 h 4 KO 7 Sb 1 / 2H 2 O and TeO 2 , and stirred and mixed to obtain a mixed solution A;

[0027] 2) Measure the ammonia water according to the volume ratio of the ammonia water and the mixed solution A as 8:100, pour the ammonia water into the mixed solution A, and sonicate for 30 minutes to obtain the mixed solution B;

[0028] 3) According to mixed solution B: reducing agent NaBH 4 The ratio is 1L: 0.08mol, choose the reducing agent NaBH 4 ; Add reducing agent NaBH in mixed solution B 4 (concentrati...

Embodiment 2

[0034] Such as figure 1 As shown, AgSbTe 2 The sonochemical preparation method of thermoelectric compound powder, it comprises the following steps:

[0035] 1) According to deionized water: AgNO 3 Ag in + : C 4 h 4 KO 7 Sb 1 / 2H 2 Sb in O 3+: TeO 2 Te in 4+ The ratio is 1L: 0.02mol: 0.02mol: 0.04mol, deionized water, AgNO 3 、C 4 h 4 KO 7 Sb 1 / 2H 2 O and TeO 2 ,spare;

[0036] Deionized water was used as solvent, followed by analytically pure AgNO 3 、C 4 h 4 KO 7 Sb 1 / 2H 2 O and TeO 2 , and stirred and mixed to obtain a mixed solution A (Ag is formed in the mixed solution A + , Sb 3+ 、 Te 4+ The concentrations of the three metal ions are 0.0166mol / L, 0.02mol / L, and 0.04mol / L, respectively);

[0037] 2) Measure the ammonia water according to the volume ratio of the ammonia water and the mixed solution A as 8:100, pour the ammonia water into the mixed solution A, and sonicate for 30 minutes to obtain the mixed solution B;

[0038] 3) According to mixed so...

Embodiment 3

[0043] Such as figure 1 As shown, AgSbTe 2 The sonochemical preparation method of thermoelectric compound powder, it comprises the following steps:

[0044] 1) According to deionized water: AgNO 3 Ag in + : C 4 h 4 KO 7 Sb 1 / 2H 2 Sb in O 3+ : TeO 2 Te in 4+ The ratio is 1L: 0.0176mol: 0.0204mol: 0.04mol, deionized water, AgNO 3 、C 4 h 4 KO 7 Sb 1 / 2H 2 O and TeO 2 ,spare;

[0045] Deionized water was used as solvent, followed by analytically pure AgNO 3 、C 4 h 4 KO 7 Sb 1 / 2H 2 O and TeO 2 , and stirred and mixed to obtain a mixed solution A (Ag is formed in the mixed solution A + , Sb 3+ 、 Te 4+ The concentrations of the three metal ions are 0.02mol / L, 0.0212mol / L, and 0.04mol / L, respectively);

[0046] 2) Measure the ammonia water according to the volume ratio of the ammonia water and the mixed solution A as 8:100, pour the ammonia water into the mixed solution A, and sonicate for 30 minutes to obtain the mixed solution B;

[0047] 3) According to mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com