Method for preparing acarbose

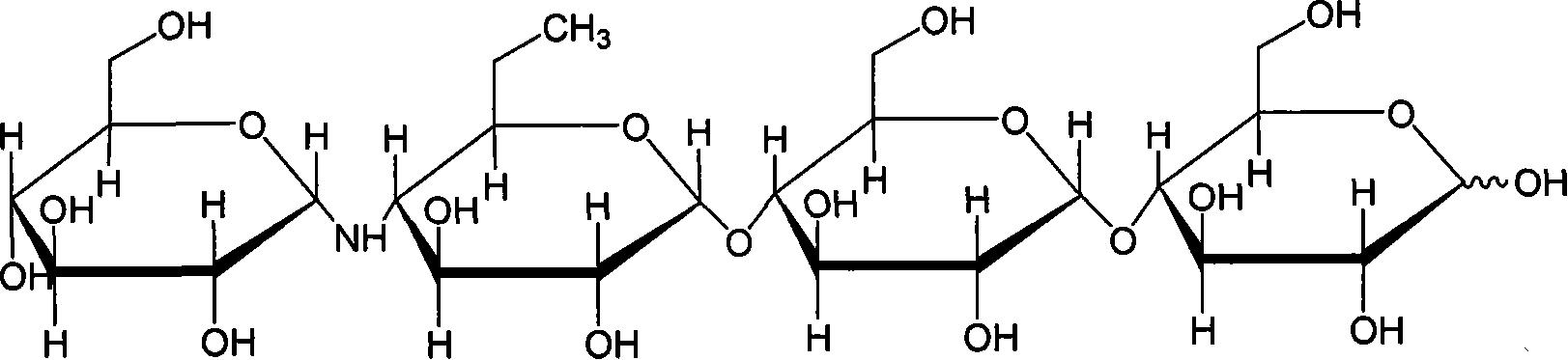

A kind of technology of acarbose and seeds, applied in the field of preparation of α-glucosidase inhibitor active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

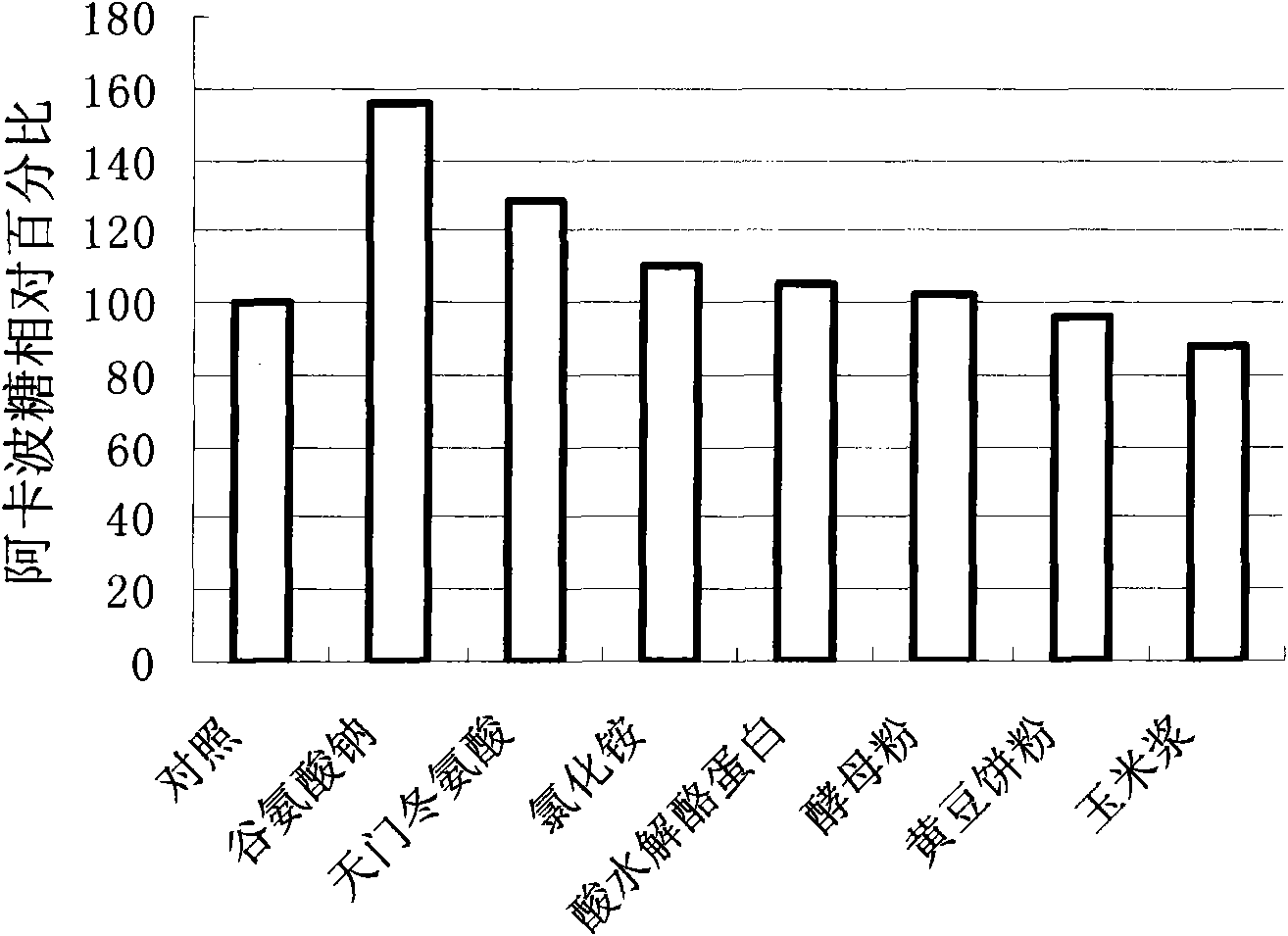

Method used

Image

Examples

Embodiment 1

[0030] (1) Inoculate the slant of Actinomyces mobilis on the slant medium, and cultivate it at 28°C for 6 days; slant medium: starch hydrolyzate 30mg / ml; peptone 5mg / ml; dipotassium hydrogen phosphate 0.6mg / ml; magnesium sulfate 0.6 mg / ml; agar 20mg / ml; pH before digestion = 7.0; medium loading 20%;

[0031] (2) Select the full-grown slant and inoculate it into the seed medium, and cultivate it for 44 hours at 28° C. and 200 rpm; seed medium: starch 10 mg / ml; glycerin 20 mg / ml; soybean cake powder (hot fried) 20 mg / ml; calcium carbonate 2mg / ml; pH before digestion = 6.8; 750ml shake flask seed medium capacity is 90ml;

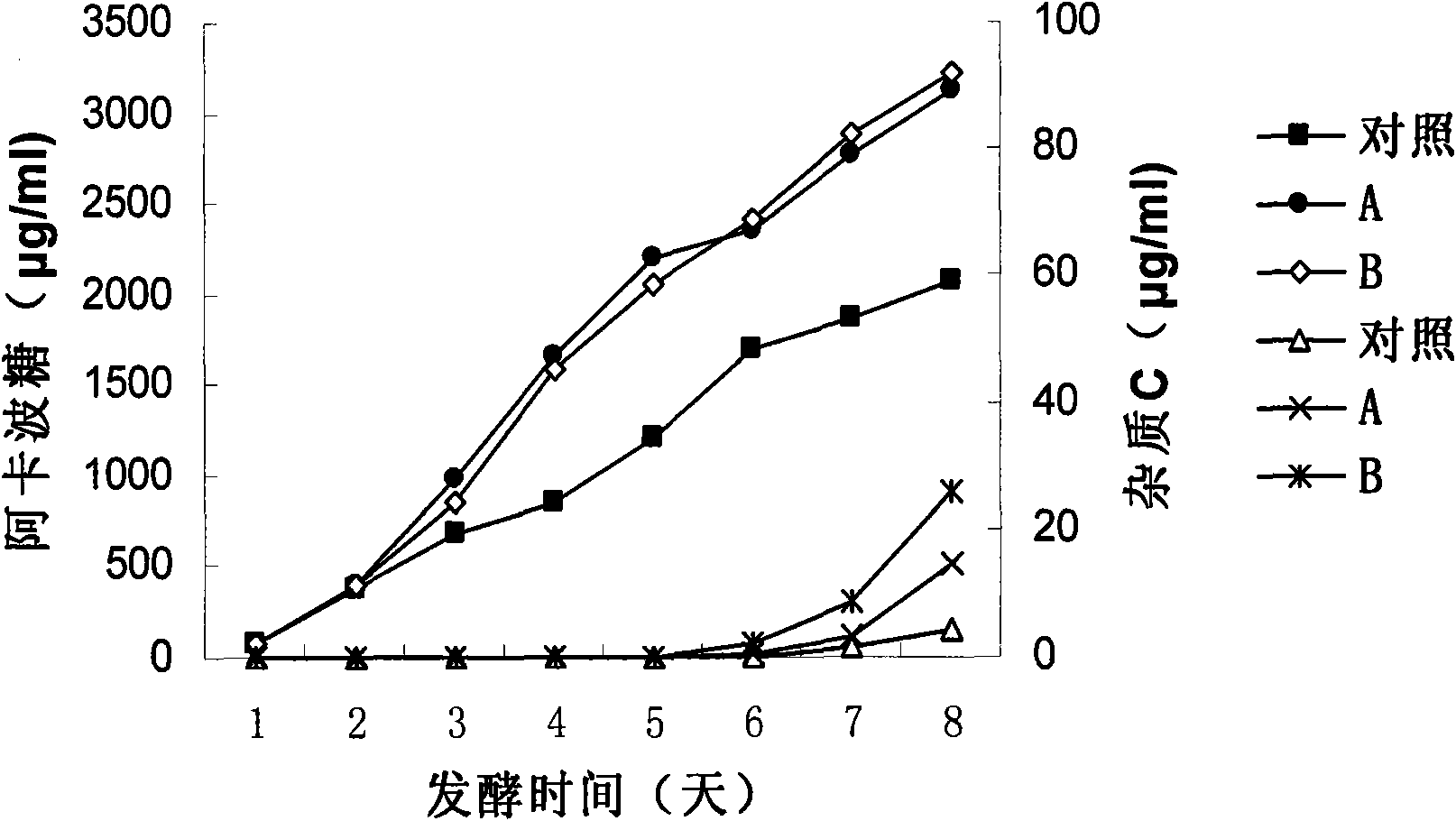

[0032] (3) Fermenter culture, after 40 hours, take samples every 6 hours to detect the content of glucose, maltose and amino nitrogen. ml and amino nitrogen 0.13mg / ml; at the same time, the unit of acarbose was detected by high-pressure liquid phase, and the unit was 2840 μg / ml after 8 days, and the content of component C was 11.6 μg / ml (accounting for 0.41wt ...

Embodiment 2

[0034] (1) Inoculate the slant of Actinomyces mobilis on the slant medium, and cultivate it at 25°C for 7 days; slant medium: starch hydrolyzate 50mg / ml; peptone 4mg / ml; dipotassium hydrogen phosphate 0.4mg / ml; magnesium sulfate 0.4 mg / ml; agar 15mg / ml; pH before digestion = 7.0; slant medium load 12%;

[0035] (2) Select the full-grown slant and inoculate it into the seed medium, and cultivate it for 48 hours at 25°C and 240rpm; seed medium: starch 8mg / ml; glycerol 15mg / ml; soybean cake powder (hot fried) 20mg / ml; calcium carbonate 2mg / ml; pH before digestion = 6.8; 750ml shake flask seed medium capacity is 150ml;

[0036](3) Fermentation tank culture, after 70 hours, take samples and detect glucose, maltose and ammonium chloride every 12 hours, add glucose, maltose and ammonium chloride according to the measurement results, so that the content is controlled at 10 mg / ml of glucose and 25 mg / ml of maltose ml and amino nitrogen 0.05mg / ml; at the same time, the unit of acarbose...

Embodiment 3

[0038] (1) Inoculate the slant of Actinomycetes mobilis on the slant medium, and cultivate it at 25°C for 6 days; slant medium: starch hydrolyzate 30mg / ml; peptone 6mg / ml; dipotassium hydrogen phosphate 0.5mg / ml; magnesium sulfate 0.5 mg / ml; agar 16mg / ml; pH before digestion = 7.0; slant medium load 15%;

[0039] (2) Select the full-grown slant and inoculate it into the seed medium, and cultivate it for 46 hours at 25°C and 220rpm; seed medium: starch 12mg / ml; glycerin 25mg / ml; soybean cake powder (hot fried) 15mg / ml; calcium carbonate 2mg / ml; pH before digestion = 6.8; 750ml shake flask seed medium capacity is 100ml;

[0040] (3) Fermentation tank culture, after 48 hours, take samples every 6 hours to detect the content of glucose, maltose and amino nitrogen, and add glucose, maltose and aspartic acid according to the measurement results, so that the content is controlled at 8 mg / ml of glucose and 23 mg of maltose / ml and amino nitrogen 0.15mg / ml; at the same time, the unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com