Proton exchange membrane for medium-high temperature fuel cell and preparation method thereof

A technology for proton exchange membranes and fuel cells, applied in fuel cells, fuel cell parts, battery pack parts, etc. to avoid catalyst poisoning and battery performance attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 4

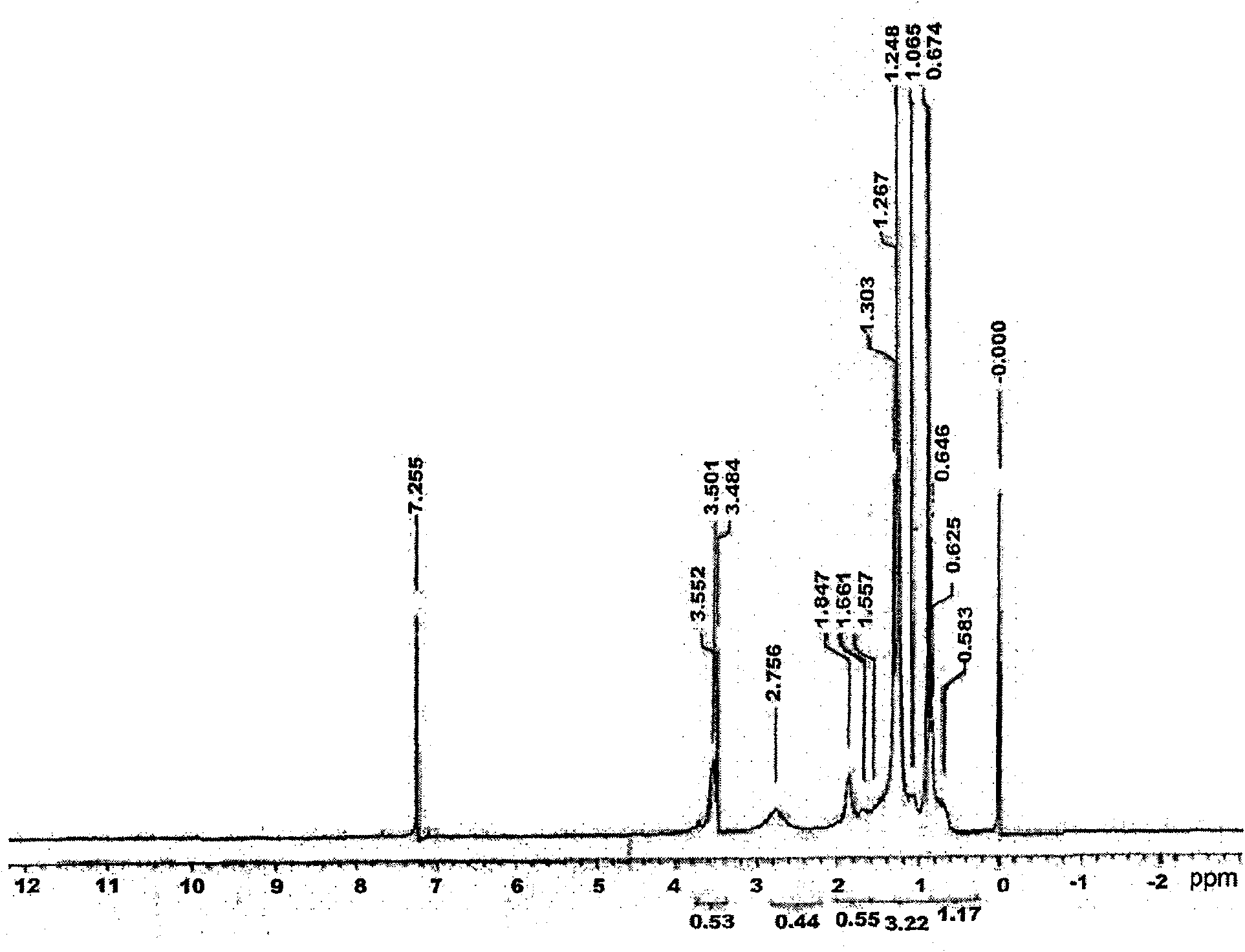

[0048] 1) Put 2.0 grams of compound N-methylimidazole in a flask, add 50 milliliters of chloropropyltrimethoxysilane, reflux for 24 hours, and remove unreacted chloropropyltrimethoxysilane by distillation under reduced pressure, and the obtained product is N -Methylimidazole grafted inorganic nanoparticle precursor, wherein imidazole and inorganic nanoparticle are connected through N-position;

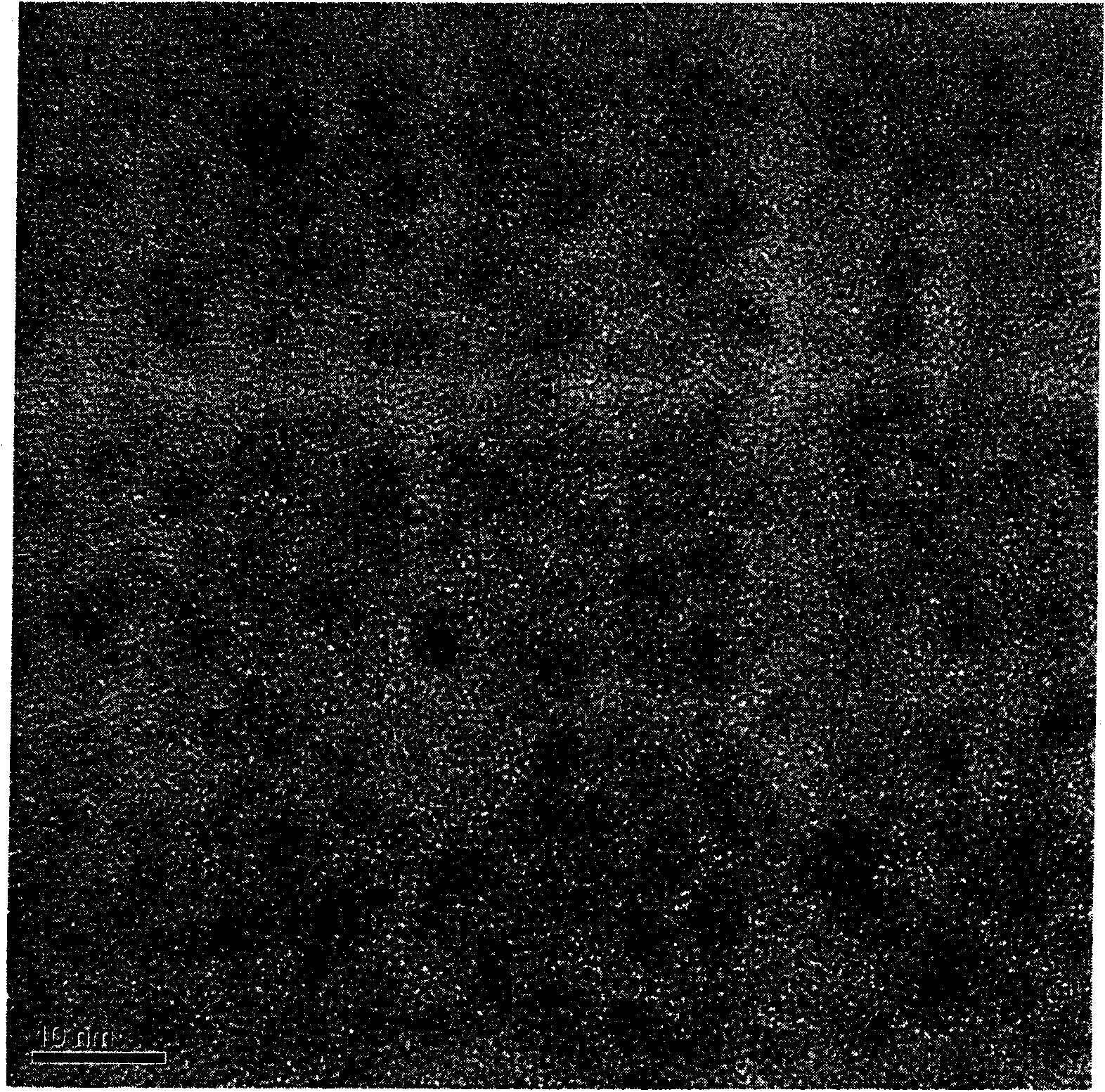

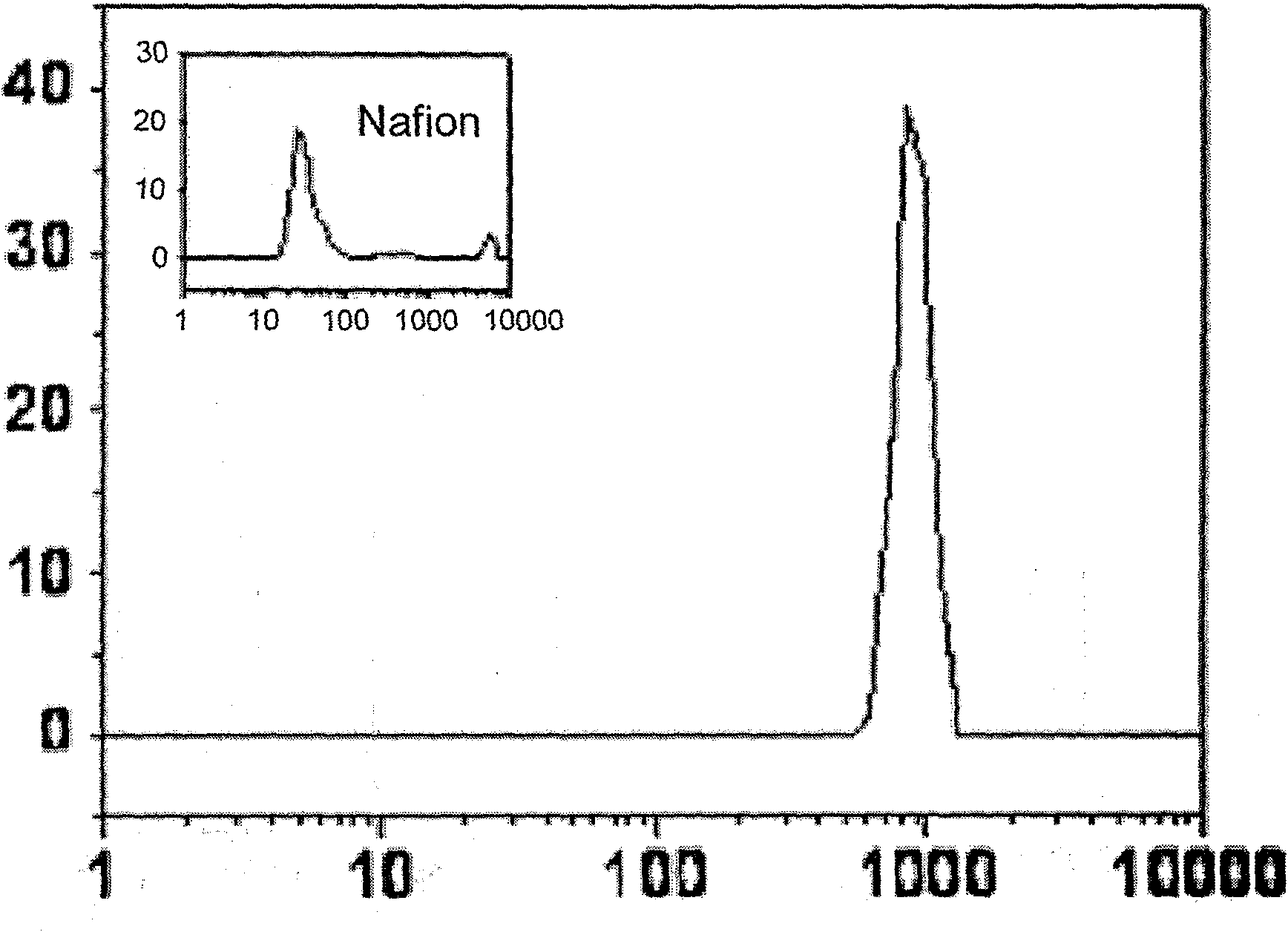

[0049] 2) Get 0.15 grams of the compound prepared in step 1, dissolve it in 2 milliliters of dry ethylene glycol, add the above solution to 10 milliliters of 5 wt% Nafion in dry ethylene glycol solution, and disperse it by ultrasonic wave for 10 minutes. 1M sulfuric acid was added dropwise to the mixed system until the pH value was 1.5, and stirred at room temperature for 10 hours. That is, the Nafion-N-methylimidazole grafted inorganic nano-silica particle dispersion system is obtained.

[0050] 3) Pour the dispersion system prepared in step 2 into a polytetrafluoroethylene petri dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com