Slice production method for treating tobacco waste extract by using membrane separation technology

A technology for the production of tobacco waste and flakes, which is applied in the treatment of tobacco, tobacco, and preparation of tobacco, etc. It can solve the problems of poor fluidity, difficulty in controlling the quality of the extract solution, unfavorable growth and reproduction of microorganisms, etc., and achieves the improvement of the quality of tobacco flakes and the separation process. Ease of control, the effect of improving the quality of tobacco sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

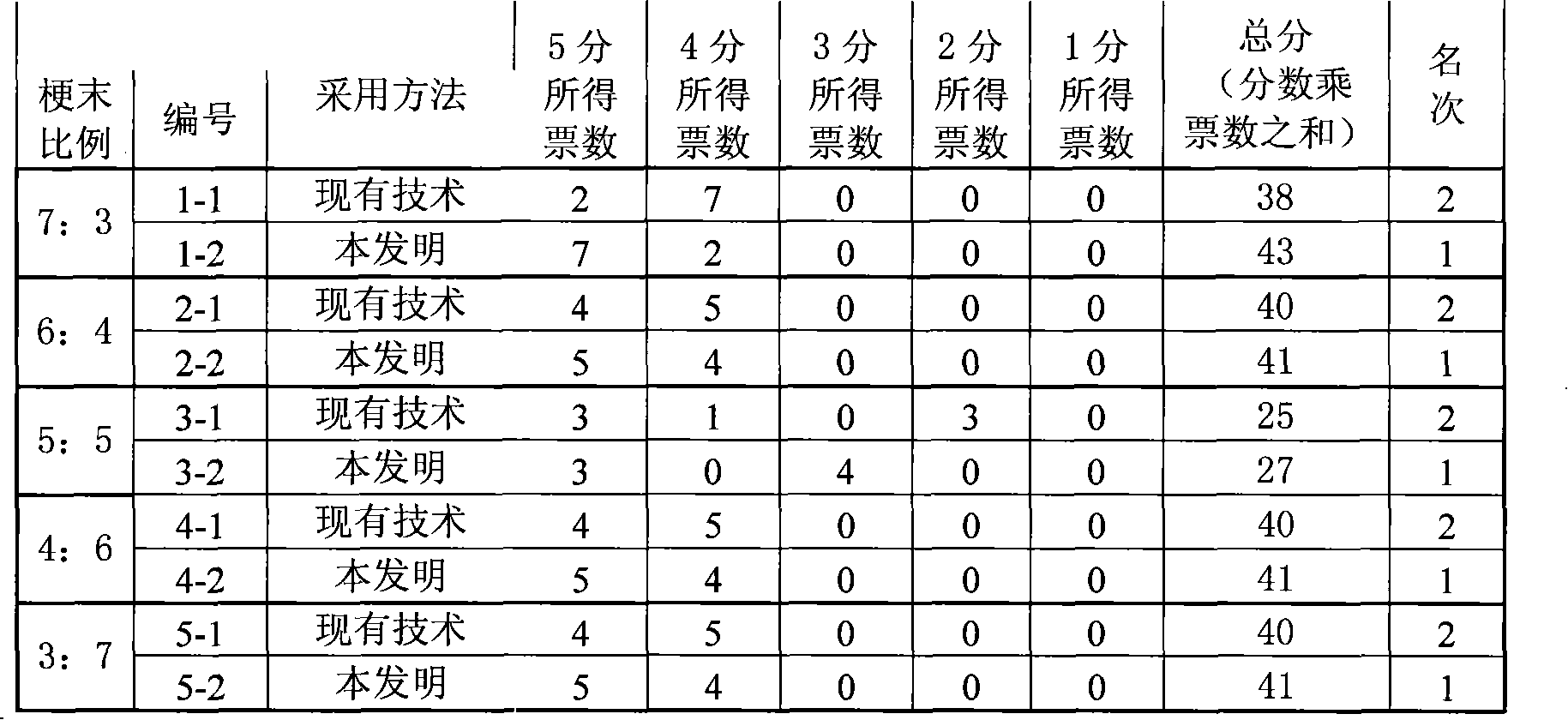

Examples

Embodiment 1

[0023] 1. Take 15kg of tobacco stems, add 5 times of water, raise the temperature to 60°C, and soak for 1 hour.

[0024] 2. Separation with a conventional centrifuge to obtain 50kg of extract. Sampling and detection of the extract showed that the total nitrogen was 3.2 mg / L and the pectin was 1.03 mg / L. The total nitrogen includes macromolecular proteins, small molecular amino acids, nicotine and other substances.

[0025] 3. Use the ultrafiltration membrane separation device to remove impurities from the extract, and the pore size of the membrane element is 7nm. The working conditions are: pressure 0.5MPa, flow velocity 4m / s, temperature 40°C, and 44kg of filtrate is obtained. The ultrafiltration filtrate was sampled and detected: the total nitrogen was 2.2 mg / L, which was 31% lower than the original extract, and pectin was not detected. The remaining total nitrogen should be small molecular nitrogen-containing substances such as amino acids and nicotine that pass through ...

Embodiment 2

[0031] 1. Take 12kg of tobacco powder, add 5 times of water, raise the temperature to 60°C, and soak for 1 hour.

[0032] 2. Separation with plate and frame to obtain 50kg of extract solution. Sampling and detection of the extract showed that the total nitrogen was 2.8 mg / L, and the pectin was 0.4 mg / L. The total nitrogen includes macromolecular proteins, small molecular amino acids, nicotine and other substances.

[0033] 3. Pass the leaching solution through an ultrafiltration membrane separation device to remove impurities, and the pore size of the membrane element is 7nm. The working conditions are: pressure 0.5MPa, flow velocity 4m / s, temperature 40°C, and obtain 41kg of filtrate. The ultrafiltration filtrate was sampled and detected: the total nitrogen was 2.1 mg / L, which was 25% less than the original extract, and the pectin was not detected. The remaining total nitrogen should be small molecular nitrogen-containing substances such as amino acids and nicotine that pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com