Method for refining terephthalic acid

A nano-carbon fiber and catalyst technology, applied in chemical instruments and methods, sustainable manufacturing/processing, separation/purification of carboxylic acid compounds, etc., to achieve high porosity, increase speed, and reduce investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] TiO 2 Sol preparation

[0053] TiO 2 The sol is produced by the hydrolysis of tetrabutyl titanate, which is a traditional sol-gel preparation method. For the preparation of TiO 2 The sol uses tetrabutyl titanate as the main raw material (the content is 97%, Aldrich), ethanol as the solvent, and nitric acid as the hydrolysis catalyst. A mixed solution containing 5 mol% tetrabutyl titanate, 90 mol% ethanol, 5 mol% deionized water and 0.1 mol% nitric acid was kept stirring at 60° C. for 30 minutes in a magnetic stirrer. Subsequently, the solution was cooled to room temperature, forming a transparent light yellow TiO 2 Sol.

Embodiment 2

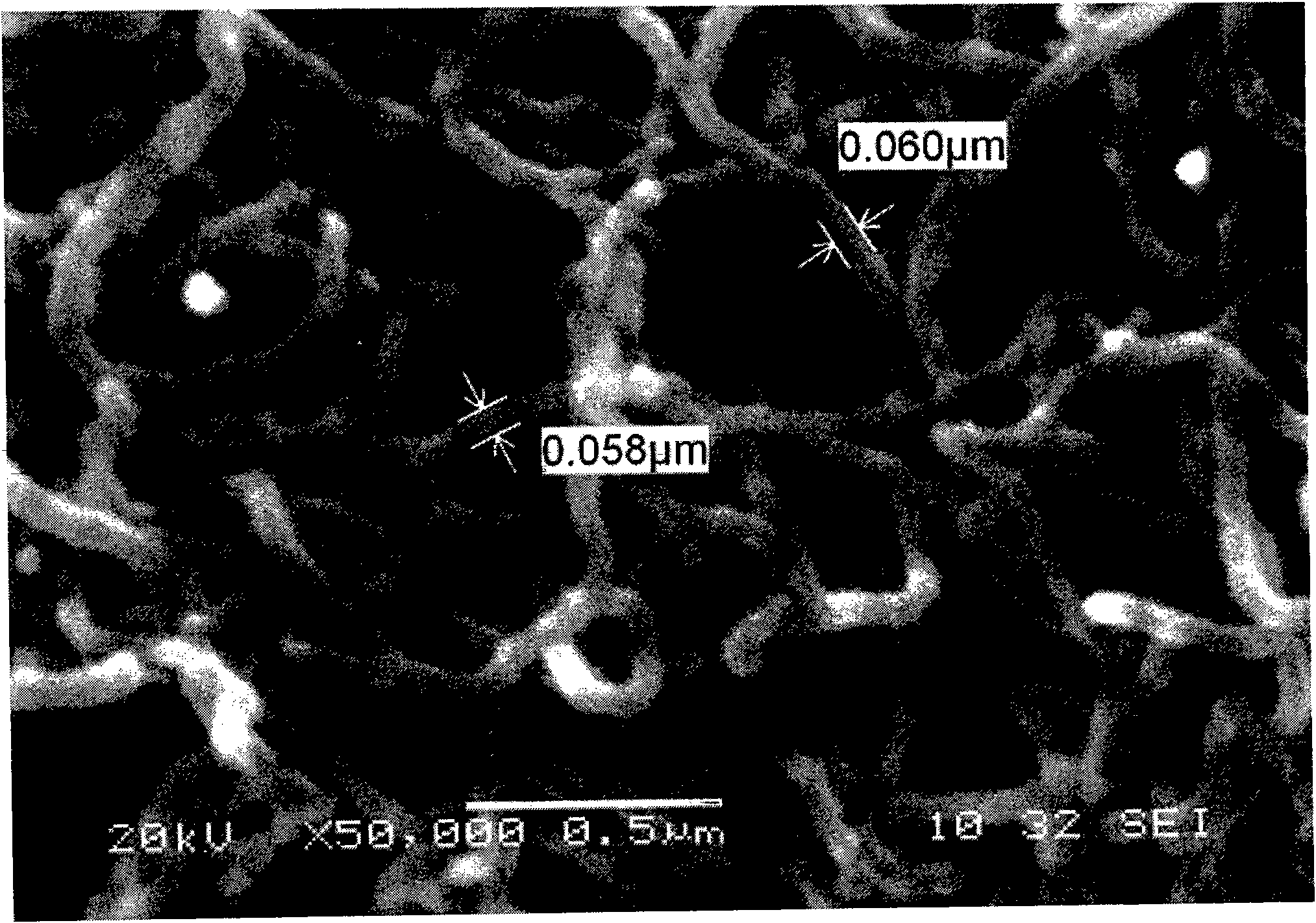

[0055] Preparation of carbon nanofiber carrier with foam structure

[0056] The metal nickel foam with a size of Φ10×5mm and an opening diameter of about 0.6mm is pretreated in the following order. First wash in dilute nitric acid solution and distilled water, and dry at 120°C for 60 minutes. The TiO prepared in embodiment 1 is used for the metal nickel foam through pretreatment 2 Sol dip coating. Slowly immerse metal nickel foam into TiO at a speed of 1cm / s 2 sol and removed immediately from the sol at the same speed to avoid excessive attachment of TiO 2 Sol. The dip-coated foam was dried overnight in a 40°C oven. The sol wrapped on the surface of the metallic nickel foam was converted into a gel film during the drying process, and then further transformed into a gel film with mesopores. Subsequently, the dip-coated foam was dried at 100 °C for 30 min and calcined at 500 °C for 2 h to finally form TiO on the foam surface 2 The protective layer. TiO 2 The thickness o...

Embodiment 3

[0061] Preparation of carbon nanofiber supports with monolith or honeycomb structure

[0062] In this example, monolith is used as a substrate for preparing structured carbon nanofibers. The size of the monolith substrate is: thickness 0.17mm, density 0.45g / cm 3 , the hole density is 400 channels / square inch. The substrate is first washed and dried, and then dip-coated with the TiO prepared in Example 1. 2 Sol and other pretreatments. The TiO 2 The sol contains nickel nitrate Ni(NiO 3 ) 2 .6H 2 O.

[0063] Immerse the monolith into TiO at a speed of 1cm / s 2 sol, and removed immediately at the same speed to avoid excessive adhesion of TiO 2 Sol. The dip-coated monolith was dried overnight in a 40°C oven. During the drying process, TiO is formed 2 Gel film, which is further transformed into a mesoporous xerogel film on the monolith surface. Subsequently, the dip-coated monolith was dried at 100 °C for 30 min and calcined at 500 °C for 2 h. After drying and calcinat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com