Wastewater treatment composite filler containing zeolite and pulverized fuel ash

A technology for wastewater treatment and composite filler, which is applied in the field of zeolite and fly ash wastewater treatment composite filler, and non-sintered porous spherical zeolite ceramsite-type composite filler, which can solve the problems of clogging, difficult zeolite particle shape, low porosity, etc. Achieve the effects of recycling resources, environmental benefits and economic benefits, obvious environmental benefits and economic benefits, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Preparation of composite filler for zeolite and fly ash wastewater treatment.

[0029] The raw materials used in the present invention are purchased from zeolite powder produced by Jiutai Zeolite Mining Company in Jilin Province, Class II fly ash (national Class I fly ash) from Jilin Yuanyuan Thermal Power Plant after electric dust removal, and 42.5 from Jidong Cement Plant in Jilin City Grade ordinary Portland cement, chemical analysis pure gypsum powder (CaSO 4 ·2H 2 O) and caustic soda (NaOH).

[0030] According to the raw material ratio determined by the experiment, weigh 5kg of zeolite powder with a fineness of 80 mesh, 2kg of national standard I grade fly ash, 0.3kg of NaOH in the fixative, and optical analysis of pure gypsum powder CaSO 4 ·2H 2 O0.6kg, 42.5 grade cement 2.1kg, water about 3kg~5kg, (that is, the amount of water used accounts for 23% to 33% of the total material, including the water for dissolving alkali and the amount of water needed for wet...

Embodiment 1、2、3

[0031] Examples 1, 2, 3; Preparation of composite filler for zeolite and fly ash wastewater treatment of the present invention.

[0032] Except for the ratio of raw materials, see Table 1 below, the rest of the preparation process, steps and other process conditions are the same as those in Example 1.

[0033] Table 1. The ratio of raw materials in Examples 1 to 3 (unit: kg)

[0034] example 1

Embodiment 4

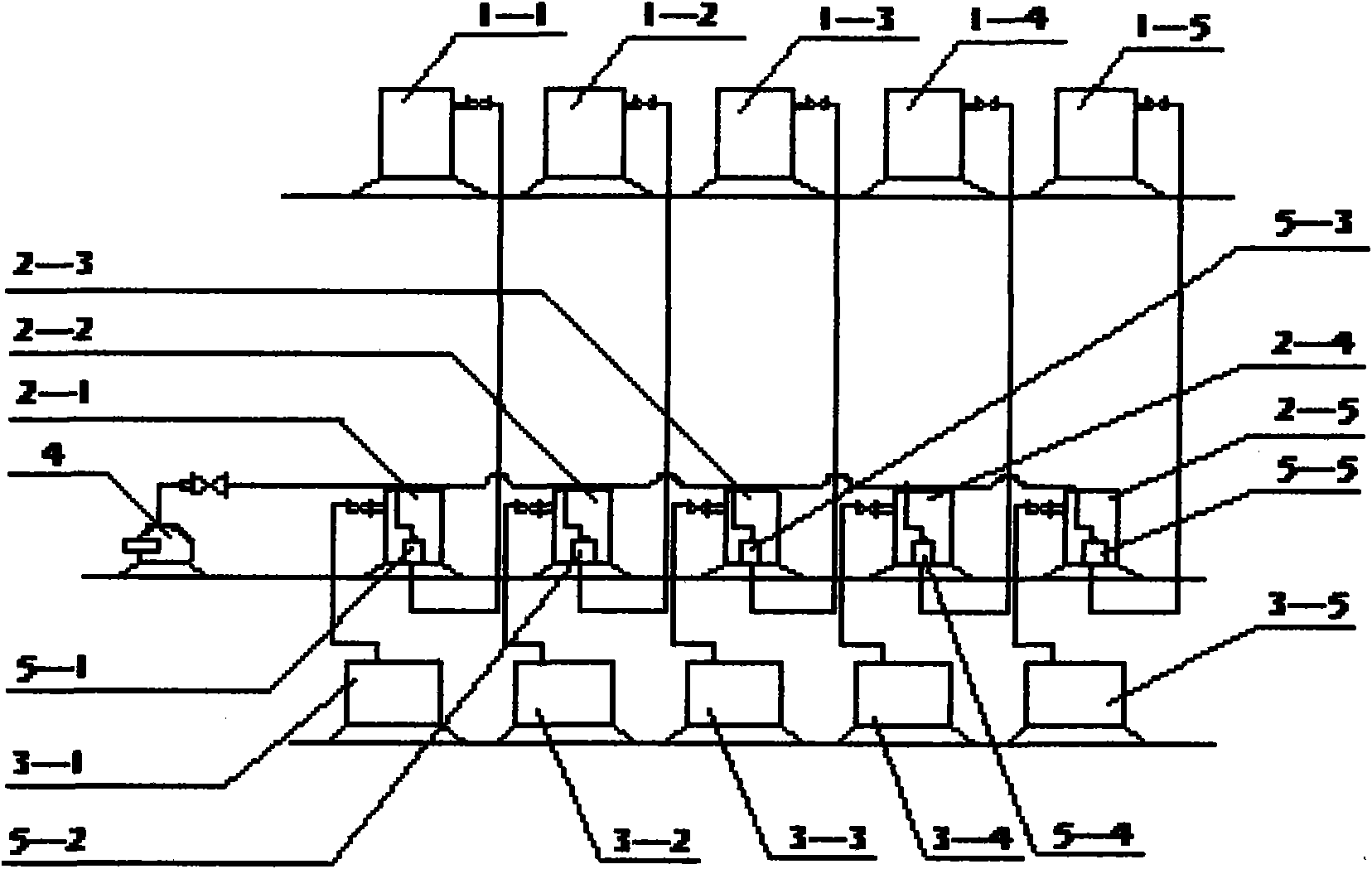

[0035] Example 4: Packing of composite fillers for zeolite and fly ash wastewater treatment of the present invention (the following 4 kinds of fillers are simultaneously packed in the same organic glass column).

[0036] Biological aerated filter is composed of filter tank body, filter material, supporting layer, water distribution system, air distribution system, backwash system, water outlet system, pipeline and automatic control system. According to the different filtering methods of wastewater in the operation of the filter, the biological aerated filter can be divided into an upward flow filter and a downward flow filter. Except for the different flow directions of wastewater in the filter, the pool structure and working principle of the upflow filter and the downflow filter are basically the same. The zeolite and fly ash wastewater treatment composite filler of the present invention, activated carbon from Tianjin Activated Carbon Factory, natural zeolite from Jiutai Zeolite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com