Organic solar cells and method of manufacturing the same

A solar cell, organic technology that can be used in final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., to solve problems such as the degree of molecular orientation limitation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

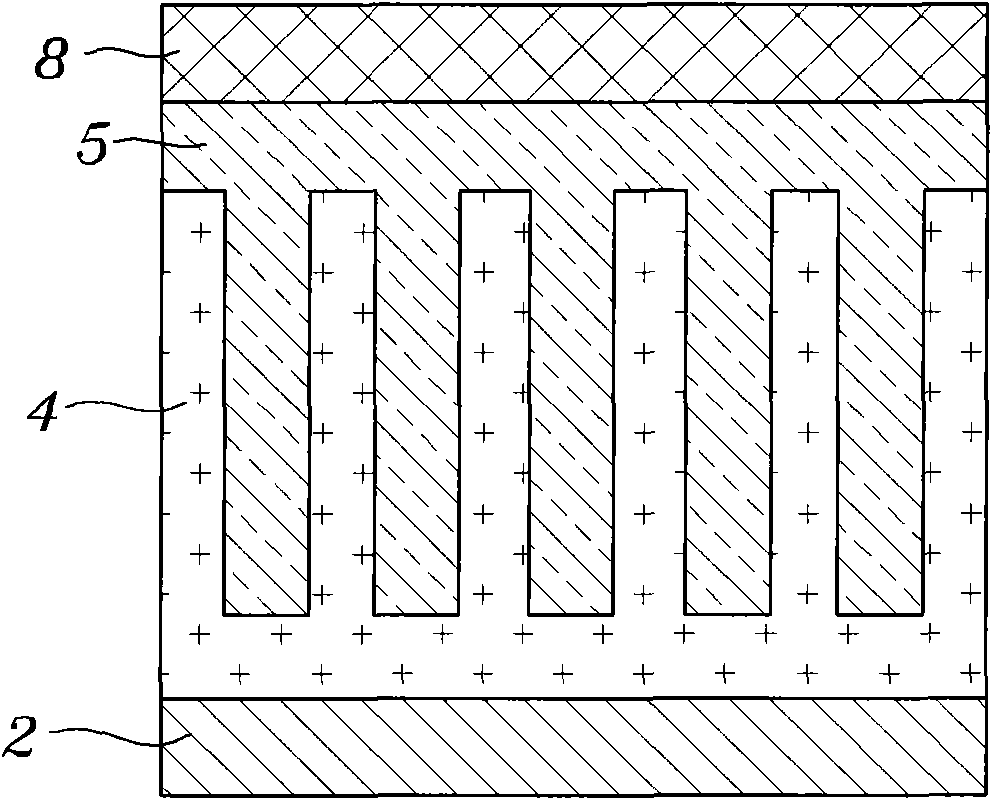

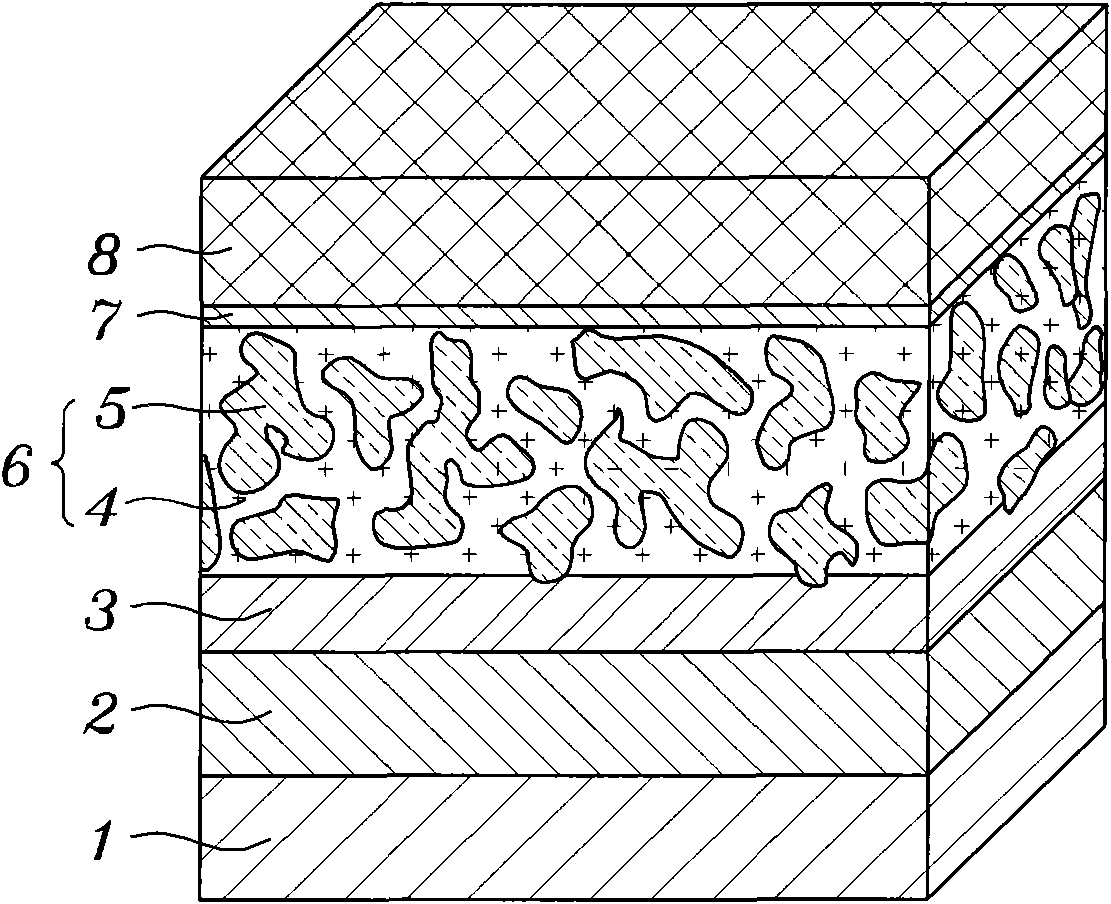

[0052] Example 1: Fabrication of organic solar cells using nanoimprinting after drying the photoactive layer

[0053] 1-1: Formation of hole transport layer

[0054] The ITO-coated glass substrate was washed with acetone and alcohol using an ultrasonic cleaner, and then subjected to plasma treatment using an oxygen plasma generator (PDC-32G, available from Harrick Plasma) in an oxygen atmosphere, thereby removing organic substances from the surface. Hydroxyl groups are formed on the surface of ITO, making the ITO surface hydrophilic. Then, poly(3,4-ethylenedioxythiophene)-polystyrenesulfonate (obtained from Bayer) was coated on the hydrophilic surface of ITO by spin coating, and then dried at 140 °C, so that the The solvent was removed, thereby forming a hole transport layer on the glass substrate.

[0055] 1-2: Formation of photoactive layer

[0056] 30 mg of electron donor material, e.g., poly-3-hexylthiophene (P3HT) and 21 mg of electron acceptor material, e.g., PCBM, we...

Embodiment 2

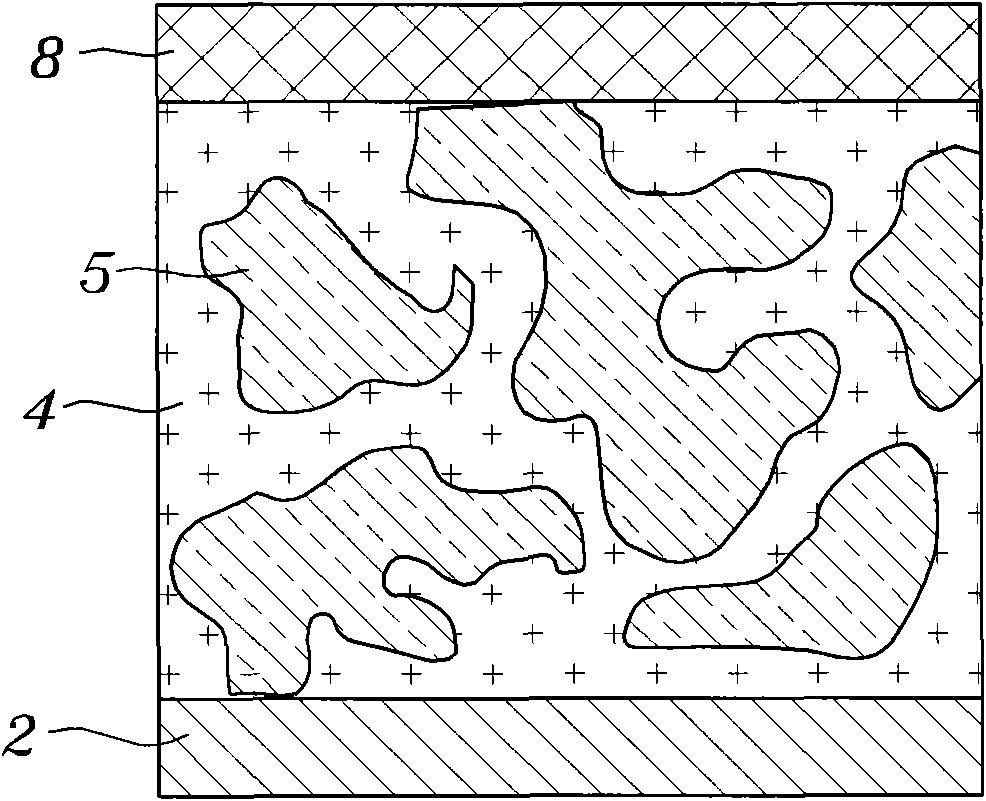

[0061] Example 2: Fabrication of organic solar cells using nanoimprinting prior to drying the photoactive layer

[0062] An organic solar cell was fabricated in the same manner as in Example 1, except that in Examples 1-2, the mixture of the photoactive layer coated on the hole transport layer was not dried, and a mold was placed in which the just-coated The solvent of the mixture is dried in a state of the mixture on the photoactive layer after the mixture.

experiment example 1

[0067] Experimental example 1: Comparison of characteristics of solar cells

[0068] The current-voltage characteristics of the organic solar cells manufactured in Examples 1 and 2 and Comparative Examples 1 and 2 were compared using a solar simulator (66984 from Newport). As a solar simulator, a 300W xenon lamp (6258 from Newport) and an AM1.5G filter (81088A from Newport) were used, and the intensity of the light was set to 100mW / cm 2 .

[0069] From Table 1 and Figure 7 From the results shown, it can be seen that compared with the organic solar cells of Comparative Examples 1 and 2, the organic solar cells of Examples 1 and 2 had very high short-circuit currents. In addition, when evaluating the effect of heat treatment for making the photoactive layer flexible during the nanoimprint process of Example 1 on the improvement of short-circuit current, because compared with the organic solar cell of Comparative Example 1 without heat treatment, no The solar cell of Comparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com