Preparation method of SnS2 nanoplate anode material of a lithium-ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in electrode manufacturing, battery electrodes, circuits, etc., to achieve high electrochemical lithium storage capacity, excellent electrochemical lithium storage performance, and good cycle stability

Inactive Publication Date: 2011-01-05

ZHEJIANG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

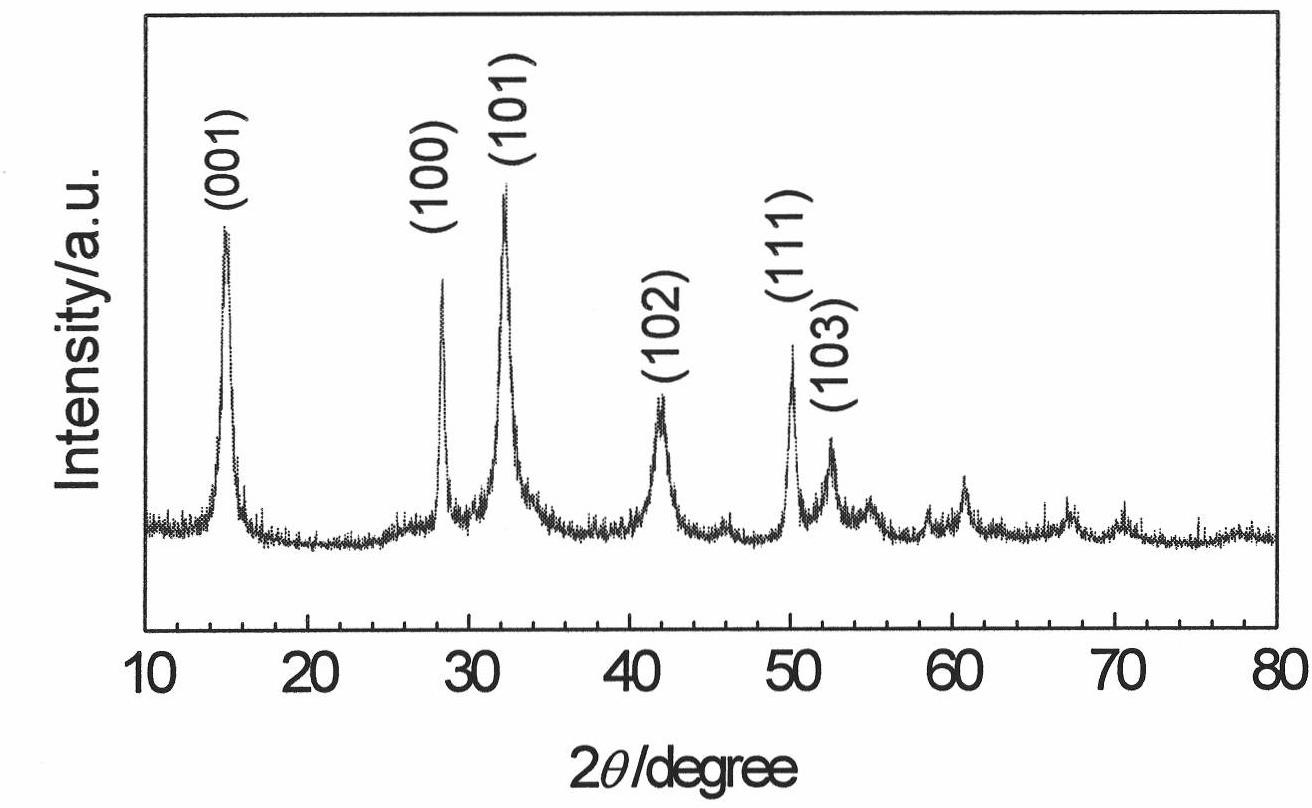

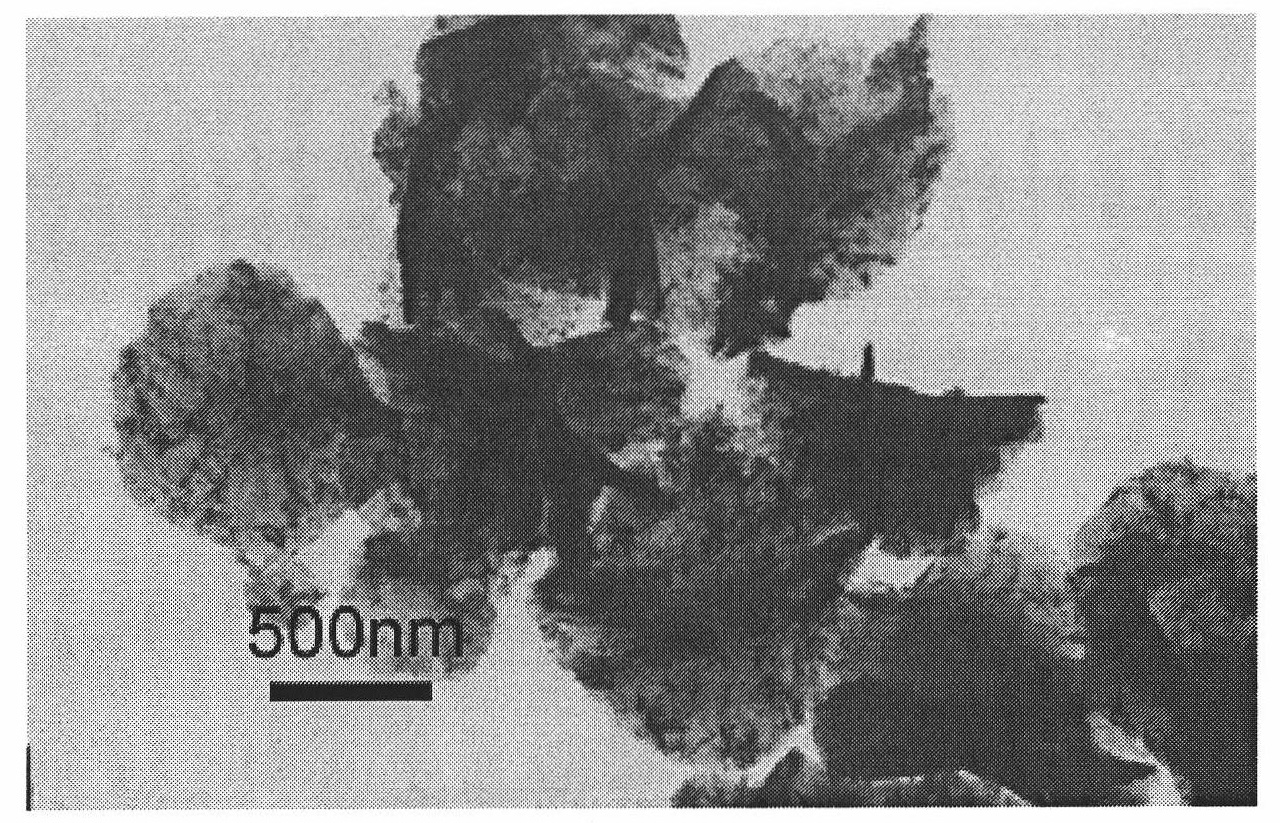

The invention discloses a preparation method of SnS2 nanoplate anode material of a lithium-ion battery, comprising the following steps: dissolving L-cysteine in deionized water, then adding stannic chloride and fully stirring the solution to dissolve the stannic chloride; transferring the mixed solution in a reaction kettle with a polytetrafluoroethylene tank to react hydrothermal reaction at 180-220 DEG C for 8-12h, then cooling to the room temperature, centrifugalizing the products to obtain precipitate, cleaning and drying the precipitate fully to obtain the SnS2 nanoplate anode material of a lithium-ion battery; wherein, the molar ratio of L-cysteine to stannic chloride is 4:1-8:1. The SnS2 nanoplate anode material of a lithium-ion battery prepared by the method of the invention has high electrochemical capacity and good cyclic stability.

Description

A kind of preparation method of lithium-ion battery SnS2 nano sheet negative electrode material technical field The invention relates to a preparation method of lithium-ion battery electrode materials, in particular to a preparation method of lithium-ion battery SnS2 nanosheet negative electrode materials, and belongs to the technical fields of inorganic material synthesis and new energy. Background technique Lithium-ion batteries have excellent properties such as high specific energy, no memory effect, and environmental friendliness, and have been widely used in portable mobile appliances such as mobile phones and notebook computers. As a power battery, lithium-ion batteries also have broad application prospects in electric bicycles and electric vehicles. At present, graphite materials (such as: graphite microspheres, natural modified graphite and artificial graphite, etc.) are mainly used as negative electrode materials for lithium-ion batteries. These graphite materials...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M4/04H01M4/58

CPCY02E60/12Y02E60/10

Inventor 李辉陈卫祥常焜赵杰

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com