Mesoporous-macroporous integral catalyst for purifying CO in hydrogen-rich gas and preparation

A monolithic catalyst and monolithic technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problems of large pressure drop and large volume, and achieve Small size, reduced size, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

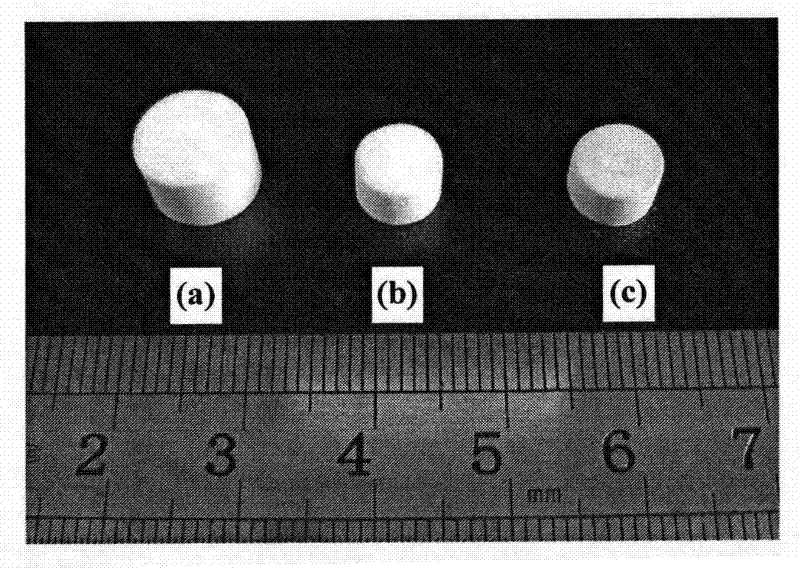

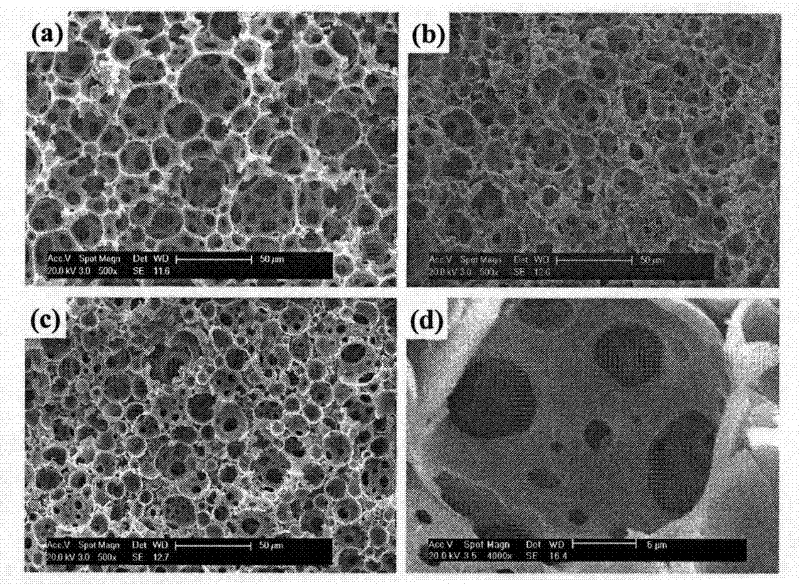

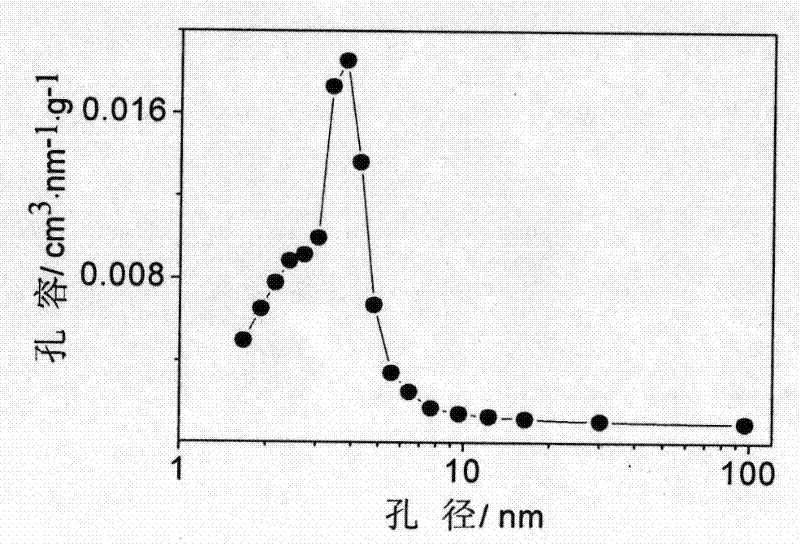

[0020] Preparation of Mesoporous-Macroporous Monolithic M-Pt-Ni / Al 2 o 3 (1:5) Catalyst

[0021] Preparation of mesoporous-macroporous monolithic catalyst: (1) Preparation of polystyrene template Styrene and divinylbenzene monomers were washed 4 times with an equal volume of 0.2mol / L NaOH solution, and then washed with an equal volume of deionized water 4 spares. Accurately weigh 6 mL of washed styrene and 1.5 mL of divinylbenzene, and put them into a 100 mL three-necked bottle. Add 0.062g of initiator azobisisobutyronitrile and 0.54g of surfactant Span 80 therein, and stir to make it evenly mixed. Slowly add 33.9 mL of deionized water (that is, the volume fraction of the aqueous phase is 82.0%) to the three-necked flask under stirring, and the dropping time is controlled at 60 min to form a reverse-phase thick emulsion. After continuing to stir for 30 minutes, the concentrated emulsion was moved into a mold, and placed in a constant temperature oven at 60°C for polymeriza...

Embodiment 2

[0025] According to the catalyst preparation steps of Example 1, the mesoporous-macroporous monolithic M-Pt-Ni / Al was prepared 2 o 3 (1: 3) catalyst, carry out the preferential oxidation of CO in the hydrogen-rich gas with this catalyst, the preferential oxidation condition is the same as embodiment 1, its result is: when 50 ℃, CO conversion rate 2.48%, selectivity 100%; 75 ℃, CO conversion rate 11.29%, selectivity 81.98%; at 100°C, CO conversion rate 30.96%, selectivity 71.02%; at 125°C, CO conversion rate 88.82%, selectivity 62.95%; at 150°C, CO conversion rate 98.52% , the selectivity is 57.72%; at 175°C, the CO conversion rate is 92.81%, and the selectivity is 48.73%; at 200°C, the CO conversion rate is 80.59%, and the selectivity is 46.73%.

Embodiment 3

[0027] According to the catalyst preparation steps of Example 1, the mesoporous-macroporous monolithic M-Pt-Ni / Al was prepared 2 o 3 (1:8) catalyst, carry out the preferential oxidation of CO in the hydrogen-rich gas with this catalyst, the preferential oxidation condition is the same as embodiment 1, its result is: when 50 ℃, CO conversion rate 5.15%, selectivity 100%; During 75 ℃, CO conversion rate 20.15%, selectivity 80.01%; at 100°C, CO conversion rate 25.15%, selectivity 62.91%; at 125°C, CO conversion rate 56.41%, selectivity 57.44%; at 150°C, CO conversion rate 83.01% , the selectivity was 56.02%; at 175°C, the CO conversion rate was 85.52%, and the selectivity was 49.11%; at 200°C, the CO conversion rate was 80.18%, and the selectivity was 42.91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com