Organic-inorganic composite anion exchange resin for adsorbing hexavalent chromium ions and preparation method thereof

A hexavalent chromium ion and inorganic composite technology, applied in the direction of anion exchange, anion exchanger material, ion exchange, etc., can solve the problems of low chromium adsorption capacity, narrow pH range, etc., achieve uniform distribution, simple operation, high ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

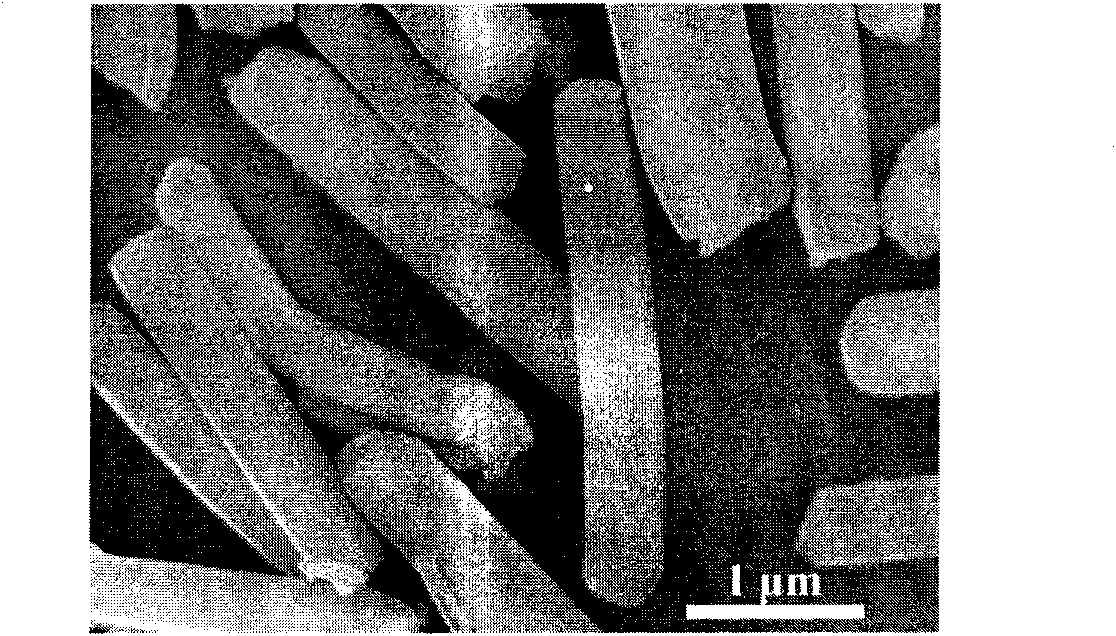

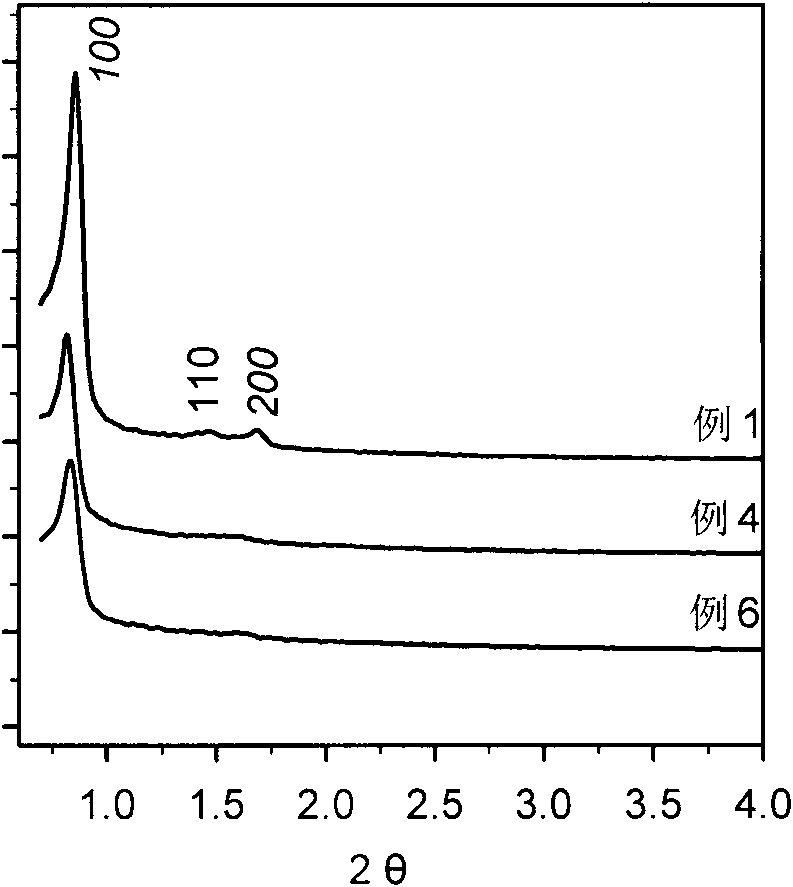

[0023] Example 1 Take 1g of P123 and 1g of NaCl, add 7.5mL of distilled water and 30mL of 2mol / L hydrochloric acid, stir until dissolved at 40°C, add 2.05mL of TEOS, stop stirring after 5min, pre-hydrolyze for 1h under static conditions, add 0.33g of MTICl After stirring for 2 minutes, stop stirring, hydrolyze for 20 hours under static conditions, put it into a polytetrafluoroethylene-lined reactor, and crystallize at 100°C for 2 days. After cooling, filter, wash, and dry. The obtained solid is placed in a fat extractor and used Ethanol extraction 24h, air-drying, obtain the chlorine type organic-inorganic composite anion exchange resin that is used to adsorb hexavalent chromium ion, this product is short stick shape, the result is as follows: figure 1 , the specific surface area is 716m 2 / g, the average pore diameter is 6.5nm. According to thermogravimetric analysis, the temperature at which the organic functional group of the product begins to decompose is 408°C.

[0024]...

Embodiment 2

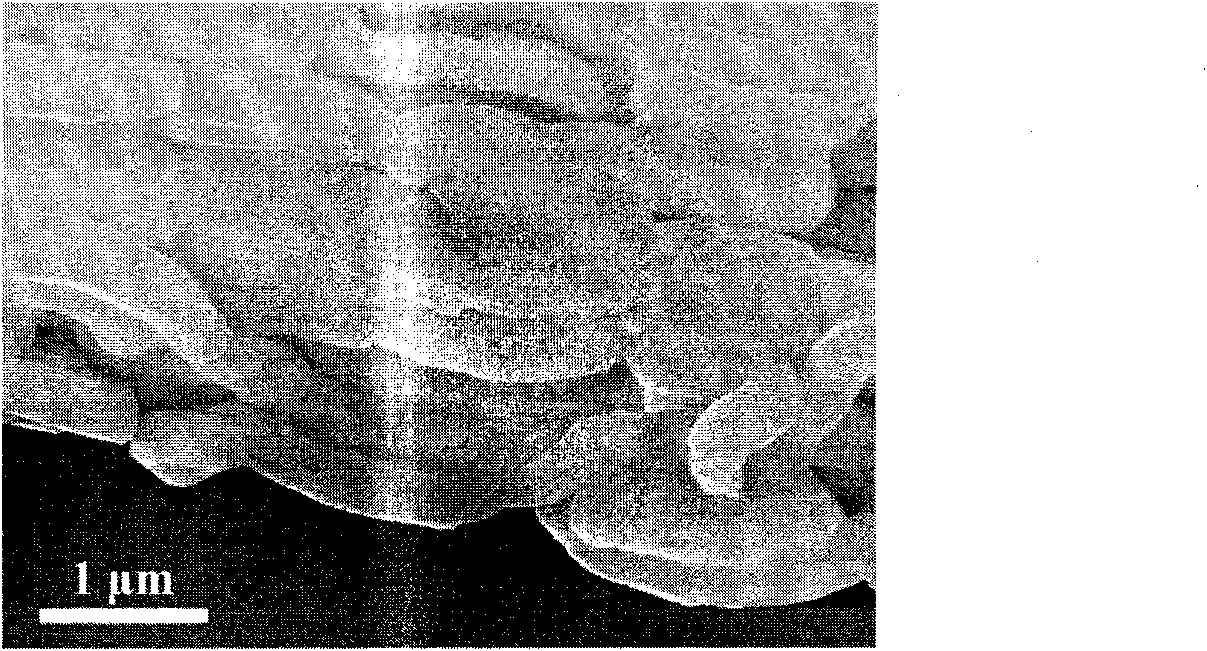

[0025] Example 2 Take 2g of P123, add 15mL of distilled water and 60mL of 2mol / L hydrochloric acid, stir until dissolved at 40°C, add 4.1mL of TEOS and stir for 1h, add 0.66g of MTICl, continue to stir for 20h, and then put the liner into polytetrafluoroethylene Crystallize at 100°C for 2 days in a reaction kettle, filter, wash, and dry after cooling. The obtained solid is placed in a fat extractor, extracted with ethanol for 24 hours, and air-dried to obtain a chlorine-type organic- Inorganic composite anion exchange resin, the product is fibrous, the result is as follows figure 2 , the specific surface area is 624m 2 / g, the average pore diameter is 6.3nm.

[0026] Get 0.01g of the chlorine-type organic-inorganic composite anion exchange resin synthesized in this embodiment and add 15mL of 100mg / L Cr(VI) solution, shake for 1h, and use spectrophotometry to detect the concentration of chromium in the remaining solution, and the adsorption capacity for chromium is 45mg / g. ...

Embodiment 3

[0027] Example 3 Take 4g of P123, add 30mL of distilled water and 120mL of 2mol / L hydrochloric acid, stir until dissolved at 35°C, add 8.2mL of TEOS, stir for 8min, stop stirring, pre-hydrolyze for 1h under static conditions, add 1.32g of MTICl, and stir for 3min Then stop stirring, hydrolyze for 24 hours under static conditions, put it into a reactor lined with polytetrafluoroethylene, crystallize at 100°C for 2 days, filter, wash and dry after cooling, put the obtained solid in a fat extractor, and extract it with ethanol 24h, air-dried, obtains the chlorine-type organic-inorganic composite anion exchange resin that is used for adsorbing hexavalent chromium ion, and this product is short stick shape, and specific surface area is 662m 2 / g, the average pore diameter is 6.3nm.

[0028] Get 0.01g of the chlorine-type organic-inorganic composite anion exchange resin synthesized in this embodiment and add 15mL of 100mg / L Cr(VI) solution, shake for 1h, and use spectrophotometry to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com