Special watermelon organic-inorganic compound fertilizer and preparation method thereof

A technology of compound fertilizer and organic fertilizer, which is applied in the field of special organic-inorganic compound fertilizer for watermelon and its preparation, can solve the problems such as the difficulty of fertilization knowledge, and achieve the effect of improving the level of scientific fertilization of watermelon, improving the quality of watermelon, and reducing the difficulty of fertilizer selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

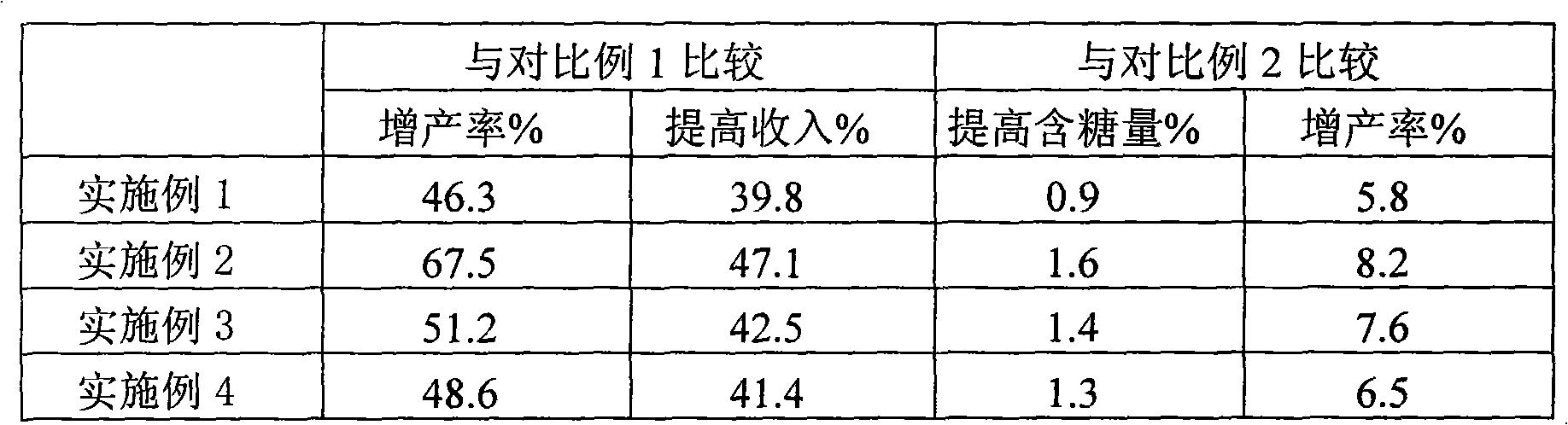

Examples

Embodiment 1

[0041] In terms of parts by mass, 30 parts of bean cake with a fineness of 20 meshes, 45 parts of xylitol residue, 13 parts of peat, 10 parts of calcium magnesium phosphate fertilizer, and 2 parts of microbial fermentation agent are fully mixed and uniform. Adjust the moisture content of the mixture to be 57%, C / N to be 27, and pH to be 7.5. Pile the mixture into a trapezoidal pile with a height of 1.5 meters, punch holes from the top down, 10 holes per square meter, cover with a plastic film, and carry out aerobic fermentation. When the temperature of the heap rises to 50°C, start timing, and ferment for 5 days. Turn the pile when the pile temperature begins to drop below 45°C, and ferment for another 4 days when the pile temperature rises above 50°C. Dry the moisture content of the fermented organic fertilizer to 30%. Take 60 parts of fermented organic fertilizer, 6 parts of urea, 24 parts of diammonium phosphate, and 10 parts of potassium sulfate. Mix all raw materials e...

Embodiment 2

[0043]In terms of parts by mass, 35 parts of cake with a fineness of 20 meshes, 37 parts of xylitol residue, 14 parts of peat, 13 parts of calcium magnesium phosphate fertilizer, and 1 part of microbial fermentation agent are fully mixed and uniform. Adjust the moisture content of the mixture to be 62%, C / N to be 25, and pH to be 7.2. Pile the mixture into a trapezoidal pile with a height of 1.8 meters, punch holes from the top down, with 14 holes per square meter, cover with a plastic film, and carry out aerobic fermentation. When the temperature of the heap rises above 50°C, start timing, and ferment for 7 days. Turn the pile when the pile temperature begins to drop below 45°C, and ferment for another 3 days when the pile temperature rises above 50°C. Air the moisture content of the above-mentioned fermented organic fertilizer to 28%. Take 65 parts of fermented organic fertilizer, 4 parts of urea, 20 parts of diammonium phosphate, and 11 parts of potassium sulfate. Mix al...

Embodiment 3

[0045] 45 parts of cottonseed cake, 15 parts of xylitol residue, 20 parts of peat, 18 parts of calcium magnesium phosphate fertilizer were used as raw materials, and 2 parts of microbial fermentation agent were added to ferment to prepare organic fertilizer. Take 50 parts of fermented organic fertilizer, 23 parts of urea, and 27 parts of potassium sulfate. All the other operations are carried out according to the method of Example 1. This fertilizer is suitable for topdressing watermelons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com