Method for measuring phthalic acid ester (PAE) in water-based adhesive for tobacco

A technology of phthalate and tobacco water-based adhesive, which is applied in the field of tobacco, can solve the problems of unestablished safety and sanitation index measurement methods, and achieve the effects of avoiding potential harm to health, accurate testing, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

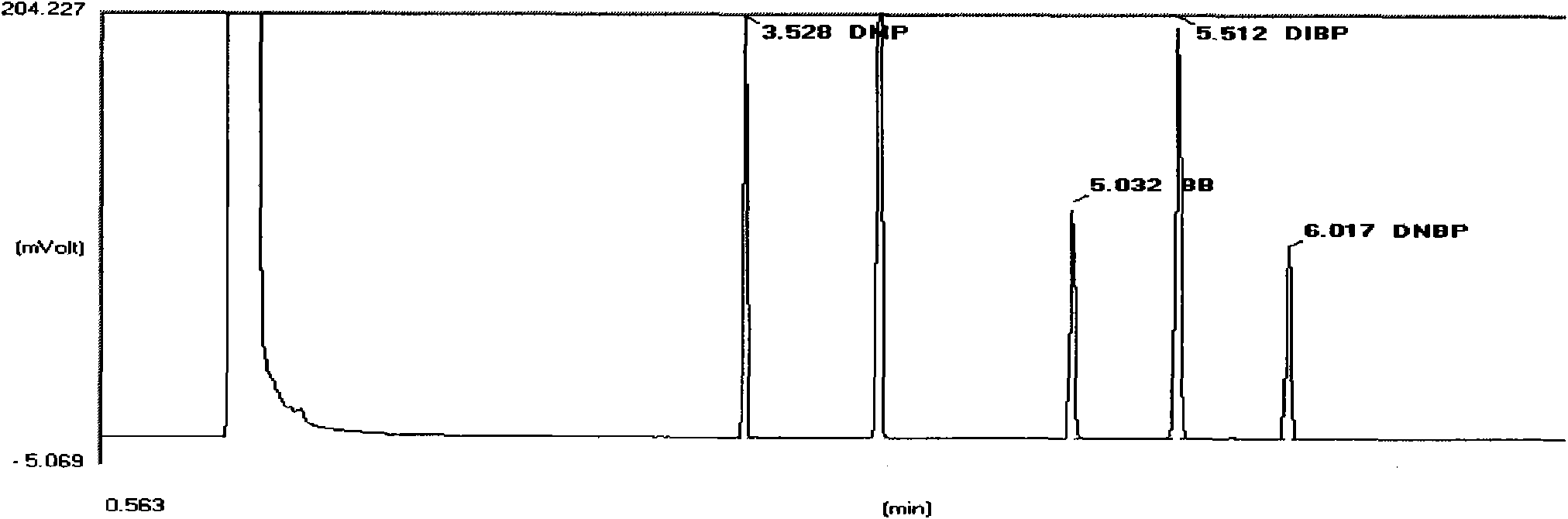

[0048] Prepare the gas chromatograph:

[0049] Adopt Agilent 6890N gas chromatograph, chromatographic column adopts HP-5 (30m * 0.32mm * 0.25 μ m), hydrogen flame ionization detector, take benzyl benzoate as internal standard; Gas chromatography conditions are as follows: carrier gas: He, Flow: 2.5ml / min; Inlet temperature: 300°C; Injection volume: 1μl, split ratio 10:1; Detector temperature: 300°C, Hydrogen flow: 30ml / min, Air: 300ml / min, Makeup gas: He, 30ml / min; the heating program is as follows: the initial temperature is 100°C, hold for 0.5min, increase to 180°C at a rate of 30°C / min, and then maintain at a rate of 15°C / min to 300°C for 10min. Preparation of standard working curve:

[0050] 1) Preparation of standard stock solution: Accurately weigh three kinds of phthalate standard products dibutyl phthalate (DNBP), diisobutyl phthalate (DIBP), dimethyl phthalate Esters (DMP) 500mg, dilute with acetone to a 100ml volumetric flask, and make a 5mg / ml mixed standard stock...

Embodiment 2

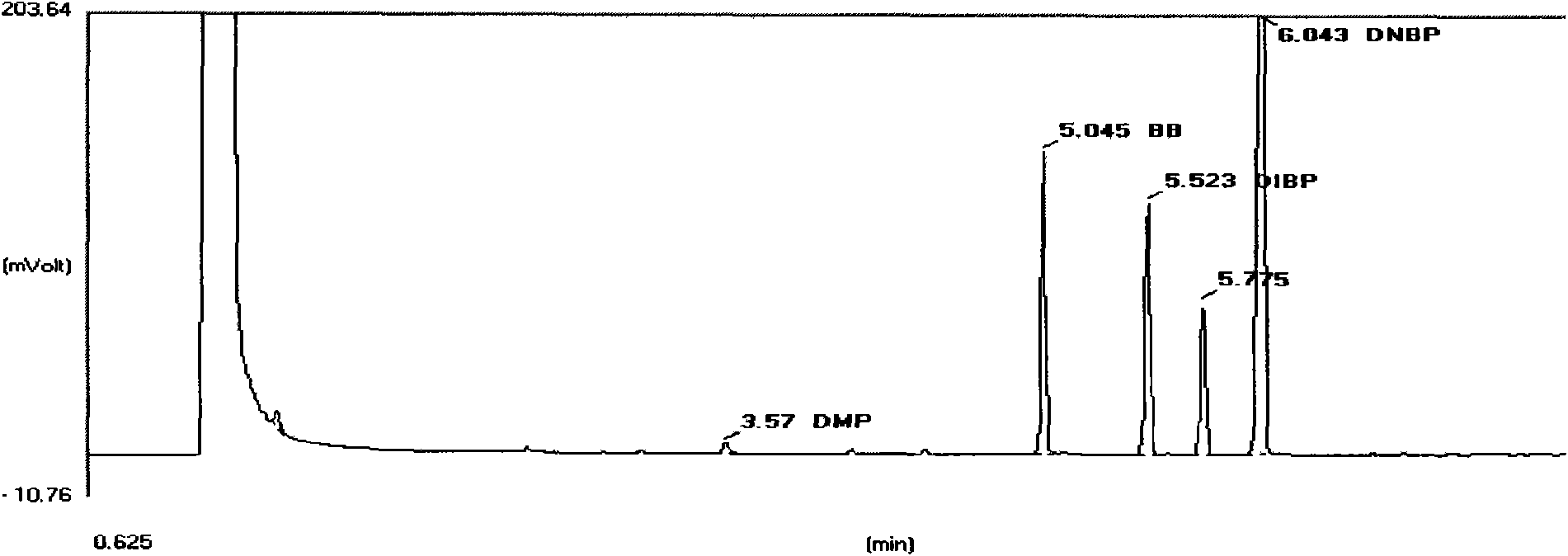

[0080] Prepare the gas chromatograph:

[0081] Adopt Agilent 6890N gas chromatograph, chromatographic column adopts HP-5 (60m * 0.32mm * 0.25 μ m), hydrogen flame ionization detector, take benzyl benzoate as internal standard; Gas chromatography condition is: carrier gas: He, Flow: 3.0ml / min; Inlet temperature: 270°C; Injection volume: 1μl, split ratio 30:1; Detector temperature: 310°C, Hydrogen flow: 35ml / min, Air: 350ml / min, Makeup gas: He, 25ml / min; heating program: initial temperature 100°C, hold for 0.5min, increase to 180°C at a rate of 30°C / min, then increase to 300°C at a rate of 15°C / min, and maintain for 10min.

[0082] Standard working solution preparation process is the same as embodiment 1, difference is in preparation standard stock solution, weighs dimethyl phthalate (DMP), diethyl phthalate (DEP), diisobutyl phthalate ester (DIBP), dibutyl phthalate (DNBP), butyl benzyl phthalate (BBP), bis(2-ethyl)hexyl phthalate (DEHP), phthalic acid Dioctyl ester (DNOP), d...

Embodiment 3

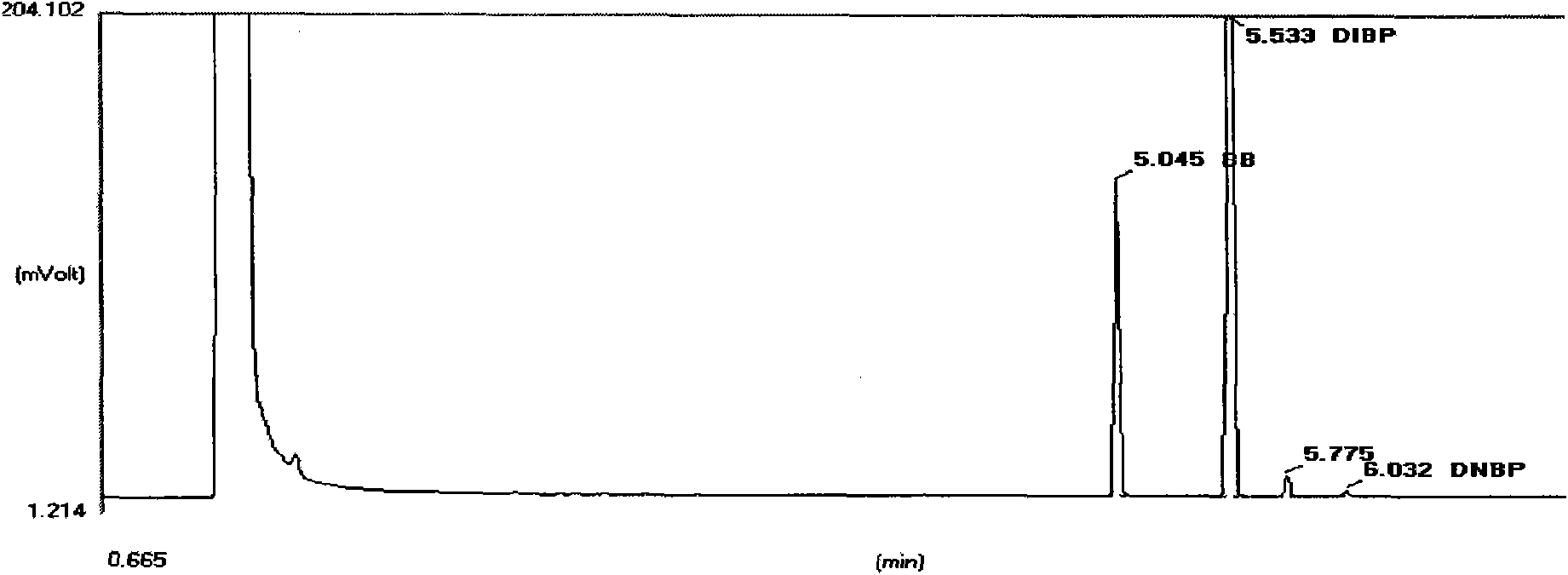

[0087] Prepare the gas chromatograph:

[0088] Adopt Agilent 6890N gas chromatograph, chromatographic column adopts HP-5 (30m * 0.32mm * 0.25 μ m), hydrogen flame ionization detector, take benzyl benzoate as internal standard; Gas chromatography condition is: carrier gas: He, Flow: 2.0ml / min; Inlet temperature: 300°C; Injection volume: 1μl, split ratio 10:1; Detector temperature: 320°C, Hydrogen flow: 30ml / min, Air: 300ml / min, Makeup gas: He, 30ml / min; heating program: initial temperature 100°C, hold for 0.5min, increase to 180°C at a rate of 30°C / min, then increase to 300°C at a rate of 15°C / min, and maintain for 10min.

[0089] The preparation of the standard working solution is the same as in Example 2.

[0090] Get the standard working solution and inject a sample under the chromatographic conditions and obtain the standard working curve, wherein the dimethyl phthalate regression equation: y=1.3985x-0.0053, R 2 =0.9999; Diisobutyl phthalate regression equation: y=1.2016x...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com